Waterproofing Solutions: Using Concrete Impregnated Fabric for Tank Linings and Reservoirs

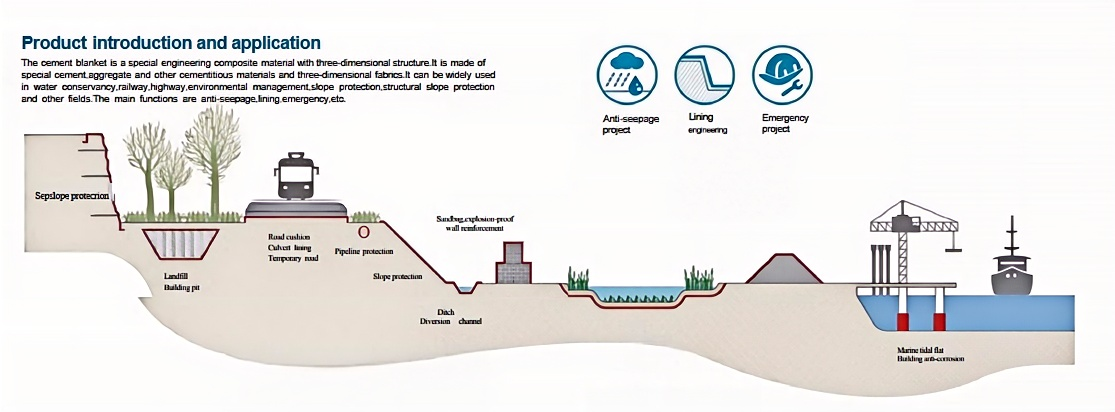

Tanks and reservoirs are vital for storing water, chemicals, and industrial fluids, however their overall performance hinges on high-quality waterproofing. Leaks now not solely waste treasured assets however additionally pose environmental risks, harm infrastructure, and lead to expensive repairs. Traditional waterproofing methods—such as inflexible concrete liners, rubber membranes, or asphalt coatings—often fail due to cracking, bad adhesion, or incapacity to adapt to structural movement. Concrete impregnated cloth has emerged as a game-changing solution, imparting flexibility, durability, and most desirable waterproofing for tank linings and reservoirs. Also acknowledged as concrete fabric fabric, this modern fabric combines the electricity of concrete with the adaptability of fabric, making it an best Ditch Lining Material and storage containment solution. This information explores how concrete impregnated cloth revolutionizes waterproofing for tanks and reservoirs, its key benefits, set up quality practices, and why it’s turning into the desired desire for engineers and contractors.

The Limitations of Traditional Waterproofing for Tanks and Reservoirs

Tanks and reservoirs face special waterproofing challenges: they need to face up to steady fluid pressure, temperature fluctuations, soil settlement, and chemical exposure. Traditional options hostilities to tackle these problems long-term:

Rigid Concrete Liners: Prone to cracking due to structural motion or thermal expansion, growing leakage factors that are difficult to repair.

Rubber Membranes: Can degrade from UV publicity or chemical contact, and require best floor coaching to keep away from delamination.

Asphalt Coatings: Become brittle over time, specially in bloodless climates, and provide confined resistance to aggressive chemicals.

Clay Liners: Have excessive permeability in contrast to synthetic solutions, main to gradual seepage and requiring thick layers that take up storage space.

These boundaries spotlight the want for a waterproofing fabric that balances strength, flexibility, and chemical resistance. Concrete impregnated material fills this hole via leveraging the fantastic houses of concrete and cloth to create a seamless, adaptive barrier.

Why Concrete Impregnated Fabric Stands Out for Waterproofing

Concrete impregnated fabric—often marketed as concrete fabric fabric—is a composite cloth consisting of a three-d cloth matrix infused with a dry concrete mix. When activated with water, the concrete hydrates and hardens, forming a inflexible but bendy water-proof layer. Its special shape promises unmatched advantages for tank and reservoir linings:

1. Superior Waterproofing and Impermeability

Once hydrated, concrete impregnated material varieties a dense, monolithic concrete layer with extraordinarily low permeability. Unlike ordinary concrete, which can improve microcracks, the material matrix bridges small gaps and prevents water or chemical seepage. This makes it best for storing potable water, wastewater, or industrial fluids, as it meets strict hygiene and environmental standards.

2. Flexibility and Adaptability

Unlike inflexible concrete liners, concrete fabric material stays bendy even after hardening. It can conform to irregular shapes, curved surfaces, and minor structural actions barring cracking. This adaptability is essential for tanks with complicated geometries or reservoirs constructed on soil inclined to settlement, as it eliminates the chance of leakage from moving infrastructure.

3. Durability and Chemical Resistance

The hardened concrete layer in concrete impregnated material is resistant to UV radiation, temperature extremes, and a huge vary of chemicals—from acidic wastewater to industrial solvents. The material matrix provides tensile strength, stopping tearing or abrasion injury from fluid motion or preservation activities. This sturdiness ensures the liner lasts for many years with minimal maintenance.

4. Versatility as a Ditch Lining Material and Beyond

While perfect for tanks and reservoirs, concrete impregnated material additionally excels as a Ditch Lining Material. It protects drainage ditches round storage amenities from erosion and leakage, growing a cohesive water-resistant device that extends from the tank to the surrounding infrastructure. This versatility reduces fabric prices and simplifies assignment logistics by using the use of a single answer for more than one applications.

Applications of Concrete Impregnated Fabric in Tank and Reservoir Waterproofing

Concrete impregnated cloth is appropriate for a vast vary of storage and containment projects, including:

1. Potable Water Tanks and Reservoirs

For storing ingesting water, hygiene and impermeability are paramount. Concrete material material is non-toxic and meets potable water standards, growing a safe, leak-free barrier that prevents contamination. Its easy floor additionally resists algae growth, lowering cleansing and renovation needs.

2. Wastewater and Sewage Tanks

Wastewater tanks require resistance to corrosive chemical compounds and organic activity. Concrete impregnated cloth withstands the acidic surroundings of sewage, stopping degradation and leakage. Its flexibility additionally contains the growth and contraction of tanks precipitated via temperature modifications or fluid levels.

3. Industrial Fluid Storage Tanks

Tanks storing oils, chemicals, or fertilizers want sturdy chemical resistance. Concrete impregnated material can be formulated with specialised components to decorate resistance to unique chemicals, making sure long-term containment except seepage. It additionally gives a competitively priced choice to pricey stainless metal or fiberglass liners.

4. Agricultural Reservoirs and Irrigation Tanks

Agricultural storage requires durable, UV-resistant waterproofing. Concrete fabric material stands up to direct daylight and harsh weather, defending water reserves for irrigation. As a Ditch Lining Material, it additionally strains irrigation ditches, stopping water loss and soil erosion.

Installation Best Practices for Concrete Impregnated Fabric

Proper set up is key to maximizing the waterproofing overall performance of concrete impregnated fabric. Follow these steps for profitable application:

1. Surface Preparation

Clean the tank or reservoir surface to cast off debris, oil, or unfastened material. Repair any cracks or uneven areas with a appropriate filler. For uneven substrates, installation a geotextile underlay to supply a smooth, secure base for the concrete impregnated fabric.

2. Fabric Cutting and Placement

Cut the concrete material cloth to healthy the tank’s dimensions, permitting for overlaps of 15–30 cm at seams. Unroll the material and function it carefully, making sure it conforms to all curves and corners. Use anchor pins or adhesive to impenetrable the material in place, stopping moving throughout hydration.

3. Hydration and Curing

Activate the cloth by way of spraying or immersing it in water, making sure the whole floor is evenly wetted. The concrete combine will hydrate and harden inside 24–48 hours, relying on temperature and humidity. Keep the material moist at some point of the curing system to make sure full energy development. Avoid taking walks on the cloth till it is thoroughly cured.

4. Seam Treatment and Quality Control

Seal overlaps with a like minded concrete sealant or through wetting the seams wholly to fuse the concrete layers. After curing, investigate the liner for any voids, tears, or incomplete hydration. Repair minor defects with patches of concrete impregnated cloth and sealant, making sure a non-stop water resistant barrier.

Conclusion: Concrete Impregnated Fabric—The Future of Tank Waterproofing

Concrete impregnated fabric, or concrete material fabric, is redefining waterproofing for tanks and reservoirs. Its special mixture of flexibility, durability, and impermeability addresses the obstacles of standard solutions, whilst its versatility as a Ditch Lining Material provides fee to whole containment systems.

For engineers, contractors, and facility managers, this cloth gives a cost-effective, long-lasting answer that reduces upkeep charges and environmental risks. Whether storing potable water, wastewater, or industrial fluids, concrete impregnated material gives you dependable waterproofing that stands up to the hardest conditions. As the demand for sustainable, adaptive infrastructure grows, concrete impregnated cloth will continue to be at the forefront of waterproofing innovation—ensuring tanks and reservoirs are leak-free, durable, and environment friendly for years to come.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province