PVC Geomembrane vs. Other Geomembranes: A Comprehensive Comparative Analysis for Optimal Project Selection

Introduction: Navigating the Geomembrane Landscape for Superior Containment

Selecting the best geomembrane for your containment undertaking is a vital choice that at once influences long-term performance, set up efficiency, and lifecycle costs. Among the array of artificial liners, Polyvinyl Chloride (PVC) geomembrane holds a wonderful and venerable position. While High-Density Polyethylene (HDPE) is frequently the default desire for large-scale tasks like an hdpe lining for ponds, and a variety of pe geomembrane merchandise are extensively available, a nuanced evaluation displays that PVC presents unmatched blessings in specific, annoying applications. This in-depth evaluation contrasts PVC geomembrane with different important types—HDPE, LLDPE, EPDM, and PP—across key overall performance parameters. We will discover how PVC's special residences make it an remarkable secure geomembrane for complicated geometries, uncovered applications, and conditions requiring finest seam integrity, assisting you make an informed, engineering-driven selection.

1. Core Material Properties and Chemical Composition

Understanding the vital polymer science in the back of every geomembrane is the first step in comparison.

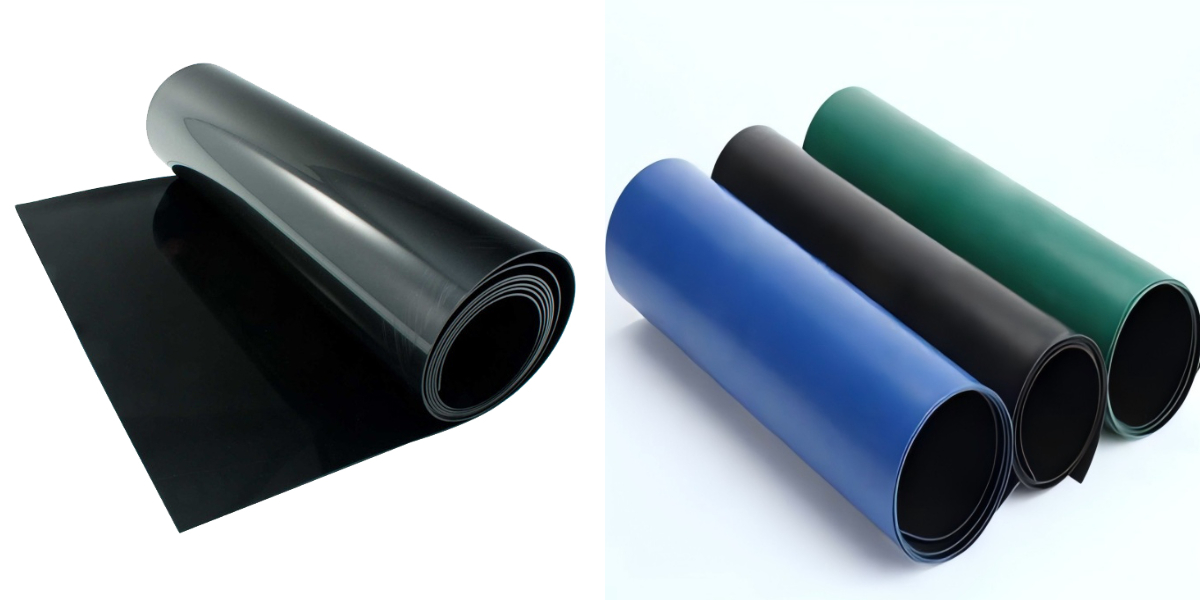

PVC Geomembrane: A flexible, thermoplastic cloth made from PVC resin, plasticizers, and stabilizers. The addition of plasticizers is what delivers PVC its famend flexibility and low-temperature performance. This formula creates an inherently invulnerable geomembrane with superb resistance to a vast vary of acids, bases, salts, and oxidizing agents.

HDPE (High-Density Polyethylene) Geomembrane: A stiff, high-strength thermoplastic made from polyethylene resin. It is characterised by using a excessive crystalline structure, giving it super tensile electricity however decrease flexibility. It is the most frequent desire for an hdpe lining for ponds, landfills, and giant reservoirs due to its strong chemical resistance and durability.

LLDPE (Linear Low-Density Polyethylene) Geomembrane: A greater bendy variant of polyethylene than HDPE. It provides higher elongation and conformability, bridging between the stiffness of HDPE and the excessive flexibility of PVC. Many current pe geomembrane merchandise designed for difficult subgrades use LLDPE or blended resins.

EPDM (Ethylene Propylene Diene Monomer) Geomembrane: A artificial rubber membrane acknowledged for its excessive elasticity, UV resistance, and tolerance to temperature extremes. It is much less frequent in massive civil initiatives however preferred in uncovered functions like ornamental ponds or roofing.

2. Head-to-Head Performance Comparison

A. Flexibility and Conformability

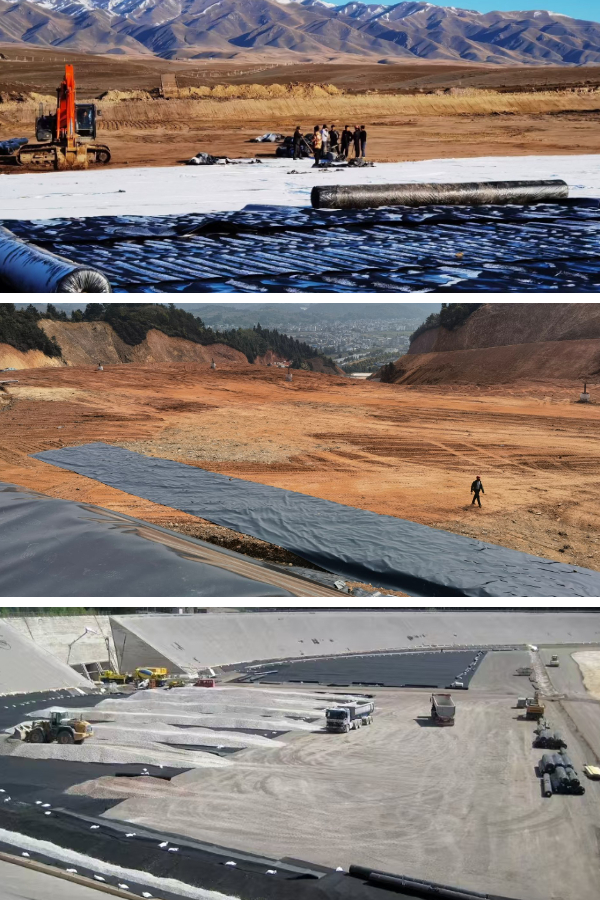

This is PVC's most decisive advantage. PVC geomembranes are extraordinarily flexible, even at low temperatures, permitting them to conform intimately to uneven subgrades, sharp contours, and complicated important points like pipes and penetrations barring stressing the material. This reduces the threat of stress cracking all through and after installation. In contrast, an hdpe lining for ponds is a whole lot stiffer, requiring a very smooth, compacted subgrade to keep away from “bridging” and factor stresses. LLDPE gives higher flexibility than HDPE however usually does now not healthy the supple nature of a well-formulated PVC.

B. Seam Strength and Integrity

Seams are the most fundamental doable failure factor in any liner system. PVC seams, created by solvent or hot-air welding, reap a actual homogeneous, chemical fusion. The ensuing seam electricity is enormously excessive and can frequently meet or exceed the power of the mother or father sheet, growing a monolithic barrier—a critical trait for a dependable invulnerable geomembrane. HDPE seams, made via thermal fusion welding, are additionally very sturdy however require flawlessly easy conditions, specialised equipment, and exceedingly professional operators. The seam is a bodily weld, which, whilst strong, can be greater touchy to set up errors.

C. Puncture and Tear Resistance

HDPE geomembranes commonly have greatest puncture resistance due to their excessive stiffness and tensile strength. This makes them perfect for functions with heavy, sharp overburden. Standard PVC has excellent puncture resistance, however it can be appreciably stronger by means of reinforcing with a polyester or fiberglass scrim, developing a bolstered composite product. In phrases of tear resistance, bendy substances like PVC and LLDPE can show off better overall performance in resisting tear propagation as soon as a puncture occurs.

D. Chemical and UV Resistance

HDPE boasts wonderful broad-spectrum chemical resistance, in particular to hydrocarbons, making it a pinnacle preference for industrial and landfill containment. PVC affords exquisite resistance to a vast array of inorganic chemicals, together with many acids and alkalis, however may also be prone to swelling from sure natural solvents and oils. Both HDPE and first-rate UV-stabilized PVC formulations provide terrific long-term resistance to sunlight. For a completely uncovered hdpe lining for ponds or ornamental feature, the precise UV components in the resin are indispensable for each types.

E. Cost and Installation Considerations

PVC regularly provides a decrease preliminary cloth value in contrast to HDPE of equal thickness. However, the most good sized fee gain often lies in installation. PVC's mild weight and flexibility permit for quicker deployment, less complicated handling, and less difficult seaming in the field, decreasing labor time and tools needs. The set up of a heavy, stiff pe geomembrane like HDPE commonly requires greater labor, heavier gear for panel placement, and greater stringent subgrade preparation, doubtlessly growing usual venture costs.

3. Application-Specific Recommendations

Choose PVC Geomembrane For:

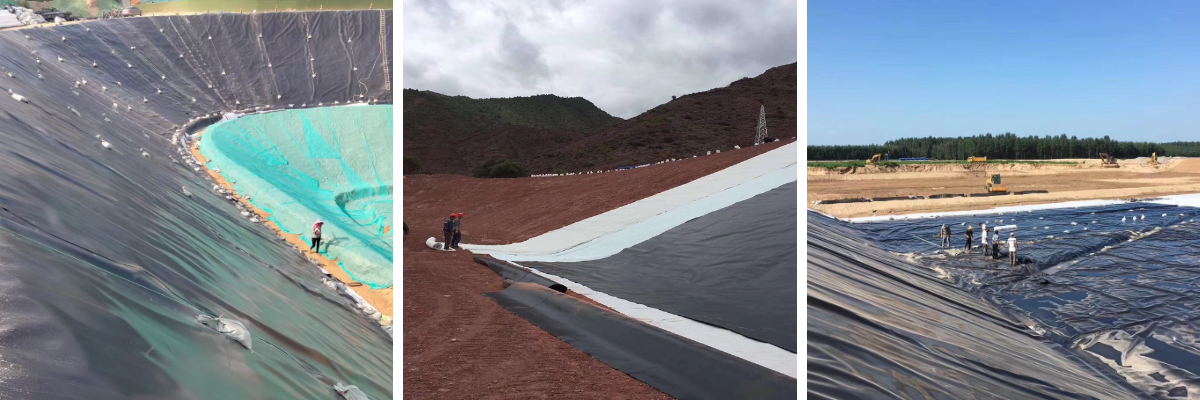

Potable water reservoirs and linings the place flexibility and robust seams are paramount.

Canal linings with complicated shapes and irregularities.

Landfill caps the place contract is expected, and the liner have to accommodate movement.

Tank linings and secondary containment with numerous penetrations.

Projects requiring a fairly dependable secure geomembrane on a hard subgrade.

Choose HDPE Geomembrane For:

Large-scale municipal and hazardous waste landfills (base liners).

Heap leach pads in mining with aggressive chemical exposure.

Large, simple-profile evaporation ponds or an hdpe lining for ponds the place subgrades can be flawlessly prepared.

Applications worrying the absolute perfect puncture resistance and huge chemical resistance.

Consider LLDPE Geomembrane For:

Projects desiring extra flexibility than HDPE however the place PVC's chemical resistance profile is no longer ideal.

Sites with a terrible or uneven subgrade the place a bendy pe geomembrane is wished to conform except excessive stress.

Conclusion: Matching Material to Mission

There is no single "best" geomembrane; there is solely the most fulfilling fabric for your particular project's conditions, stresses, and lifetime requirements. While HDPE and different pe geomembrane merchandise are extremely good for large, aggressive containment, PVC geomembrane stands out as the premier desire for initiatives annoying most appropriate flexibility, seamless conformity, and awesome seam integrity.

For engineers and undertaking managers, this comparative evaluation underscores that for water containment, difficult geometries, and purposes the place set up effectivity without delay influences finances and schedule, PVC gives a compelling, high-performance solution. It promises the self belief of a virtually invulnerable geomembrane with the sensible advantages that streamline building and make certain long-term, leak-free performance. Always seek advice from with a certified geosynthetics engineer to function a site-specific evaluation, making sure your chosen liner is no longer simply adequate, however flawlessly engineered for success.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province