The Lifecycle Cost of HDPE vs. Other Liner Materials

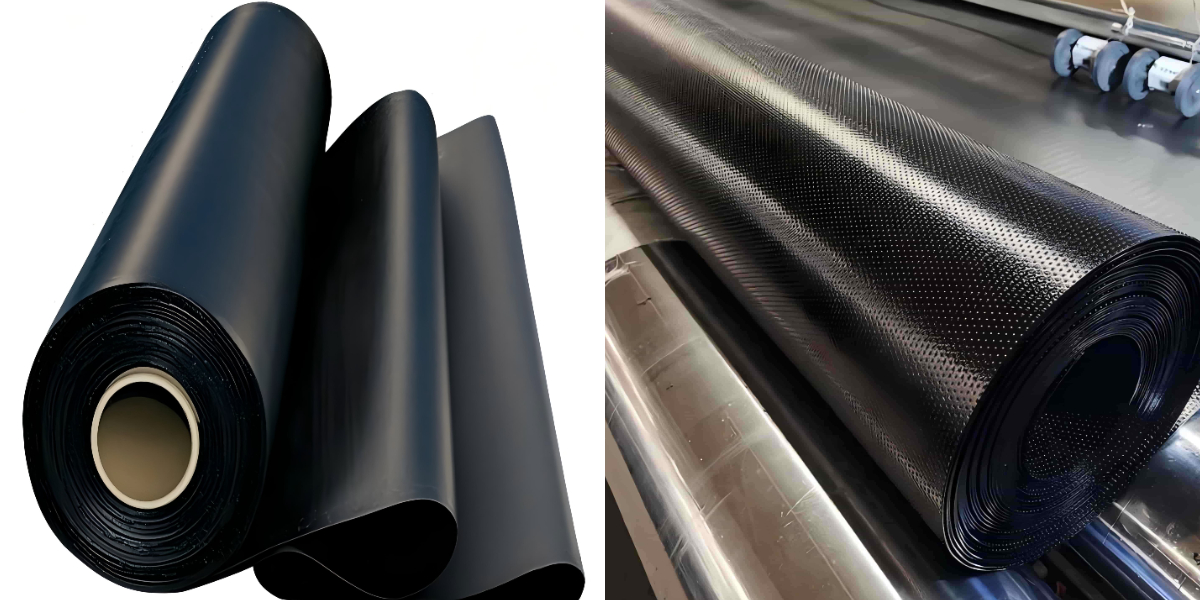

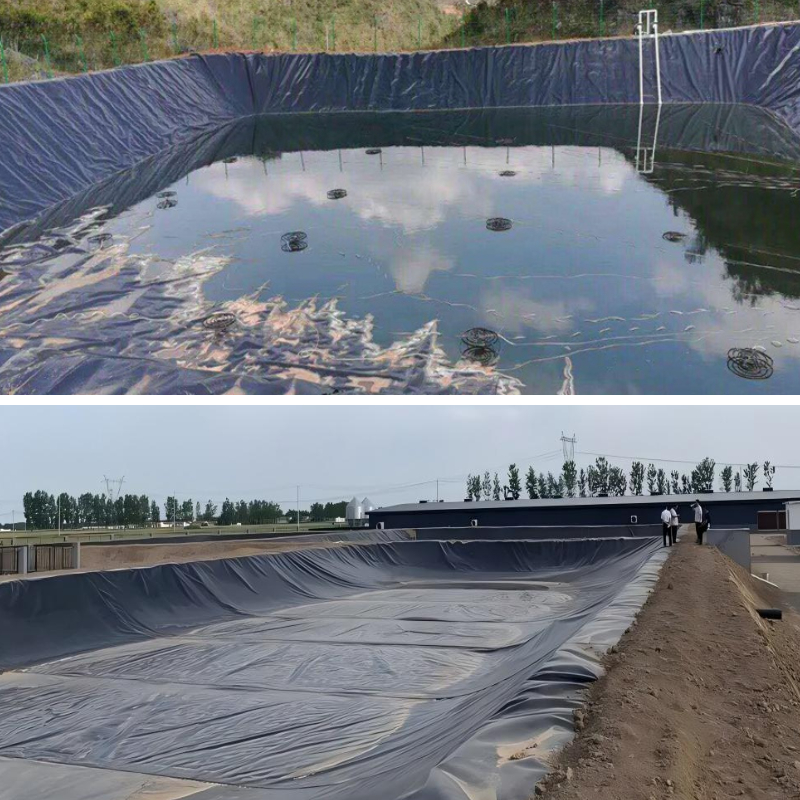

When deciding on liner substances for functions like landfills, water reservoirs, or industrial containment systems, upfront value is regularly a preliminary consideration—but lifecycle price gives a greater complete view of long-term value. HDPE geomembrane has emerged as a main preference in liner systems, thanks to its durability, chemical resistance, and low upkeep requirements. However, grasp how its lifecycle value compares to different liner substances requires evaluating elements past buy price, which include geomembrane set up expenses, preservation needs, alternative intervals, and overall performance reliability. This information breaks down the lifecycle value of HDPE geomembrane versus different frequent liner materials, highlighting the function of impermeable geomembrane residences and ideal set up in maximizing long-term value.

What Is Lifecycle Cost, and Why Does It Matter for Liner Materials?

Lifecycle value encompasses all fees associated with a liner cloth from procurement to disposal, inclusive of buy price, geomembrane set up labor and materials, maintenance, repairs, and eventual replacement. For containment projects, the place liner failure can lead to luxurious environmental injury and regulatory penalties, lifecycle price is a extra dependable indicator of fee than upfront value alone. Impermeable geomembrane substances like HDPE are designed to limit long-term charges via lowering leakage dangers and extending carrier life. By evaluating lifecycle costs, venture managers can make knowledgeable selections that stability finances constraints with overall performance and durability, making sure that the chosen liner fabric promises the pleasant return on funding over the project’s lifespan.

HDPE Geomembrane: Key Lifecycle Cost Advantages

HDPE geomembrane affords numerous lifecycle value blessings that set it aside from different liner materials. First, its inherent sturdiness and resistance to chemicals, UV radiation, and environmental stressors imply it requires minimal protection over time. Unlike some liner substances that degrade rapidly beneath harsh conditions, HDPE geomembrane keeps its impermeable geomembrane residences for decades, decreasing the want for common repairs or replacements. Second, geomembrane set up for HDPE is notably efficient, in particular when working with skilled teams. While set up expenses might also fluctuate based totally on challenge complexity, the long-term financial savings from decreased upkeep and alternative frequently offset any preliminary investment. Additionally, HDPE geomembrane is recyclable at the give up of its provider life, doubtlessly decreasing disposal prices and aligning with sustainable challenge goals. These elements mix to make HDPE geomembrane a low-budget preference when evaluating complete lifecycle expenses.

Comparing HDPE to Other Common Liner Materials

HDPE vs. PVC Geomembrane

PVC geomembrane is some other famous impermeable geomembrane option, however its lifecycle value regularly exceeds that of HDPE. While PVC can also have a decrease upfront buy price, it is extra prone to chemical degradation and UV damage, main to extra everyday preservation and previously replacement. Geomembrane set up for PVC additionally requires specialised strategies to forestall harm to the material, which can enlarge labor costs. Over time, the cumulative costs of repairs and substitute make HDPE a greater low-priced preference for most long-term containment projects.

HDPE vs. Clay Liners

Clay liners have been used for many years in containment systems, however their lifecycle fee is generally greater than HDPE geomembrane. Clay liners require vast website practise and compaction to reap impermeable properties, using up preliminary set up costs. They are additionally susceptible to cracking and erosion over time, which can compromise their effectiveness and require pricey repairs or reinforcement. In contrast, HDPE geomembrane’s flexible, seamless format reduces the danger of leakage and requires minimal maintenance, making it a greater low-cost preference over the lengthy term. Additionally, geomembrane set up for HDPE is much less based on web site conditions, lowering the threat of fee overruns due to bad soil quality.

HDPE vs. Concrete Liners

Concrete liners provide excessive structural power however come with sizeable lifecycle price drawbacks in contrast to HDPE geomembrane. Concrete set up is labor-intensive and expensive, and the cloth is inclined to cracking, specially in areas with temperature fluctuations or floor movement. Repairs to concrete liners are expensive and time-consuming, and the material’s permeability can extend over time as cracks form. HDPE geomembrane, through contrast, is bendy and resistant to cracking, preserving its impermeable geomembrane houses even with minor floor movement. Its decrease set up and preservation expenses make it a extra good value choice for most containment applications, in particular these requiring long-term reliability.

The Impact of Geomembrane Installation on Lifecycle Cost

Proper geomembrane set up is a fundamental issue in minimizing the lifecycle price of HDPE geomembrane and different impermeable geomembrane materials. Poor set up can lead to wrinkles, seams that fail, or punctures, all of which amplify the chance of leakage and steeply-priced repairs. Working with skilled set up groups ensures that HDPE geomembrane is exact anchored, seamed, and covered, maximizing its sturdiness and decreasing long-term renovation needs. Additionally, investing in great set up materials—such as like minded adhesives and seam tapes—prevents untimely failure and extends the provider existence of the liner. While exceptional set up might also require a barely greater preliminary investment, it offers tremendous financial savings over time by way of fending off steeply-priced repairs and replacements.

Maximizing the Lifecycle Value of HDPE Geomembrane

To in addition optimize the lifecycle fee of HDPE geomembrane, mission managers have to prioritize suited protection and monitoring. Regular inspections can discover small issues—such as minor punctures or seam damage—before they improve into most important problems. Prompt repairs the use of well matched substances assist preserve the impermeable geomembrane houses of HDPE and lengthen its carrier life. Additionally, defending the liner from bodily damage—such as from heavy tools or sharp objects—reduces the want for repairs. By following these practices, undertaking groups can make sure that HDPE geomembrane offers most fee over its whole lifecycle, reinforcing its role as a most economical liner material.

Conclusion: HDPE Geomembrane as a Lifecycle Cost Leader

When evaluating the lifecycle fee of liner materials, HDPE geomembrane persistently outperforms options like PVC, clay, and concrete. Its durability, low upkeep requirements, and environment friendly geomembrane set up technique mix to supply long-term fee that upfront value on my own can't match. The impermeable geomembrane residences of HDPE reduce leakage risks, decreasing the doable for luxurious environmental penalties and repairs. For challenge managers searching for a cost-effective, dependable liner solution, HDPE geomembrane presents the first-rate stability of performance, durability, and lifecycle value. By investing in pleasant HDPE geomembrane and acceptable installation, corporations can make certain that their containment structures supply dependable overall performance for many years whilst minimizing long-term expenses.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province