Key Advantages of Using a Cement Blanket Over Traditional Concrete Pouring

Introduction: Revolutionizing Concrete Application

For decades, the go-to approach for growing a durable, shielding concrete floor supposed dealing with the logistical challenges of standard concrete pouring: mixing, forming, pouring, curing, and the inherent mess and delay. Today, a cutting-edge engineered alternative—the cement blanket—offers a paradigm shift. This flexible, fabric-like composite hardens into a thin, high-strength concrete layer upon hydration. When evaluating it to standard strategies for initiatives like culvert lining, bund lining, or changing a degraded plastic ditch liner, the blessings of a cement blanket are now not simply incremental; they are transformative in phrases of speed, cost, and versatility.

1. Unmatched Speed and Simplicity of Deployment

The most immediately and impactful gain is the dramatic discount in task timeline.

No Formwork or Mixing: Traditional pouring requires constructing and putting off complicated timber or steel forms, a time-consuming and labor-intensive process. It additionally requires on-site batching of concrete with mixers. A cement blanket eliminates each steps entirely. The cloth arrives pre-mixed and equipped to deploy.

Rapid Installation: A crew can unroll, cut, and impenetrable a cement blanket in a fraction of the time wanted to set up forms. For repairing a failing culvert lining or developing emergency bund lining round a spill, this pace is critical. The blanket can be established and made traffic-ready inside hours, no longer days.

Immediate Curing: While typical concrete requires 7-28 days to attain full layout strength, a cement blanket units rapidly. It turns into walkable in about 1-2 hours and positive aspects big load-bearing ability inside 24 hours, notably decreasing downtime for indispensable infrastructure.

2. Superior Versatility and Conformability

Traditional poured concrete is inflexible and great suitable to simple, available geometries. Cement blankets excel in complicated or restrained environments.

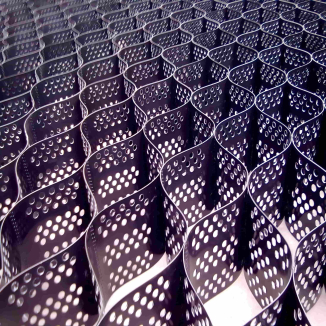

Adapts to Any Shape: The bendy cloth conforms flawlessly to uneven surfaces, tight corners, and complicated curves besides cracking. This makes it perfect for lining irregular culvert lining interiors, wrapping round pipes, or overlaying slopes the place constructing a shape would be impractical or impossible.

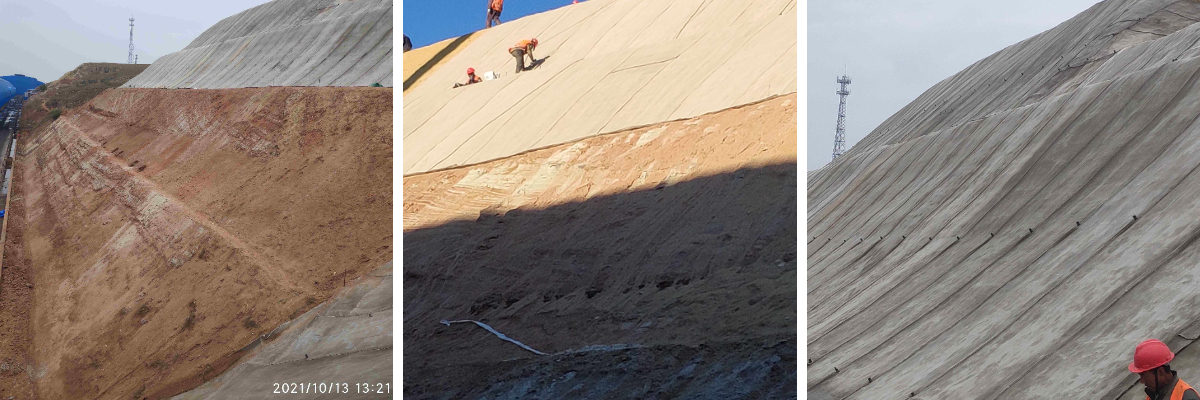

Ideal for Slopes and Vertical Surfaces: Pouring concrete on a slope is notoriously difficult. A cement blanket can be effortlessly draped, stapled, and hydrated in place, making it best for slope protection, channel lining, and vertical bund lining the place it acts as a rapid-sealing barrier.

Direct Overlay: It can regularly be set up at once over a prepared, secure substrate or even an existing, failing floor like a torn plastic ditch liner, growing a new armored floor except the want for whole demolition.

3. Enhanced Material Performance and Durability

Beyond logistical benefits, the cement blanket presents precise overall performance traits that frequently surpass normal skinny concrete pours.

Controlled, Consistent Thickness: Traditional hand-poured concrete on slopes or ditches regularly suffers from inconsistent thickness, main to vulnerable points. A cement blanket affords a uniform, engineered thickness (typically 5-15mm) throughout the complete application, making sure predictable overall performance as a dependable culvert lining or ditch armor.

High Early Strength and Flexibility: The composite of fiber matrix and fine-aggregate concrete creates a fabric with suitable flexural electricity and crack resistance, permitting it to face up to minor substrate motion higher than a brittle, skinny concrete pour.

Excellent Durability: Once cured, it varieties a durable, abrasion-resistant, and weatherproof surface. For hydraulic functions like ditch lining, it affords some distance most excellent erosion and UV resistance in contrast to a plastic ditch liner, which can degrade and emerge as brittle over time.

4. Significant Cost and Logistics Benefits

The effectivity of the cement blanket interprets without delay into bottom-line financial savings and decreased venture complexity.

Reduced Labor and Equipment Costs: Eliminating formwork, mixing, pumping, and great ending labor leads to important value savings. Installation requires solely primary hand equipment and a water source.

Minimal Material Waste: With ordinary concrete, over-ordering is frequent to make sure adequate supply, main to waste. Cement blankets are reduce to precise measurement on-site, absolutely removing waste.

Lower Transportation and Site Impact: A roll of cement blankets consists of the equal of more than one cubic meters of concrete in a lightweight, compact form. This reduces truck traffic, gas costs, and on-site storage space—a necessary gain for faraway web sites or touchy environmental areas the place setting up a bund lining is necessary.

5. Application-Specific Advantages

For Culvert and Ditch Lining: Installing a cement blanket for culvert lining is a one-day operation versus a multi-day form-and-pour process. It creates a seamless, joint-free indoors that improves hydraulics and resists scour. It is the definitive improve from a flimsy plastic ditch liner, presenting permanent, structural protection.

For Bund Lining and Secondary Containment: Speed is security in spill containment. A cement blanket approves for the speedy introduction or restore of an impermeable bund lining round gasoline tanks or chemical stores, offering immediately compliance and environmental protection.

For Emergency and Remote Repairs: Its light-weight nature and easy set up make it the solely sensible desire for pressing repairs in areas the place concrete vans and crews can't without difficulty access.

Conclusion: The Modern Standard for Concrete Protection

The preference between a standard concrete pour and a cement blanket is no longer simply about fabric preference; it is about selecting an outdated, resource-intensive method versus a modern, efficient, and high-performance system. For purposes requiring a durable, shielding concrete layer—whether for indispensable culvert lining, impervious bund lining, or changing an insufficient plastic ditch liner—the cement blanket can provide overwhelming blessings in speed, adaptability, cost, and completed quality. It transforms concrete utility from a heavy, sluggish development venture into a rapid, specific deployment operation. By adopting this technology, challenge managers and engineers can acquire higher consequences faster, with much less danger and decrease complete cost, putting a new fashionable for overall performance and effectivity in shielding lining projects.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province