Infrastructure Applications: Concrete Impregnated Fabric for Culverts, Canals, and Pipes

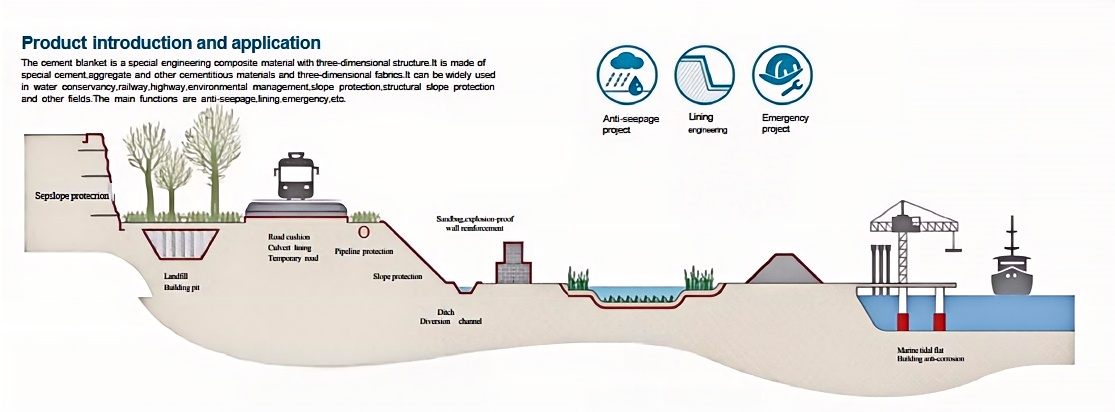

Infrastructure like culverts, canals, and pipes is the spine of water management, transportation, and city development—but it’s continuously below chance from corrosion, erosion, and structural degradation. Traditional building and restore strategies for these belongings are regularly costly, time-consuming, and disruptive, requiring heavy equipment, prolonged closures, and massive crews. Concrete impregnated material has emerged as a transformative solution, redefining how we build, repair, and hold imperative infrastructure. Its revolutionary Instant Concrete Mat variations allow fast deployment, whilst its sturdiness and versatility make it an best Ditch Lining Material and structural reinforcement. This information explores how concrete impregnated cloth revolutionizes infrastructure projects, its key advantages for culverts, canals, and pipes, installation pleasant practices, and why it’s turning into the favored preference for engineers and contractors worldwide.

The Limitations of Traditional Infrastructure Materials

Culverts, canals, and pipes face special challenges that take a look at the limits of usual materials:

Corrosion and Erosion: Metal pipes rust, concrete buildings crack, and earthen canals erode due to water flow, chemical exposure, and weathering.Slow Construction/Repair: Building or repairing with usual concrete requires formwork, curing time (often weeks), and heavy machinery—disrupting traffic, water flow, or close by communities.High Costs: Material transport, labor, and downtime pressure up fees for standard projects, specifically in far flung or hard-to-access areas.Rigidity: Rigid materials like concrete or steel can’t adapt to soil movement, main to cracks and leaks over time.

These barriers demand a answer that’s durable, flexible, speedy to deploy, and cost-effective—qualities that concrete impregnated material provides seamlessly.

Why Concrete Impregnated Fabric Excels for Infrastructure

Concrete impregnated cloth is a composite fabric consisting of a woven or nonwoven cloth matrix infused with a dry, high-performance concrete mix. When activated with water, it hydrates and hardens into a rigid, load-bearing shape with the electricity of usual concrete however the flexibility of fabric. For infrastructure applications, its key residences include:

Rapid Hardening: Instant Concrete Mat versions harden in hours, now not days, lowering assignment timelines from weeks to days (or even hours for repairs).

Flexibility and Conformability: It wraps round curved surfaces (like pipes) and conforms to irregular shapes (like culvert interiors), removing the want for customized formwork.

Durability: Once hardened, it’s resistant to corrosion, abrasion, chemical exposure, and UV radiation—outlasting ordinary concrete in harsh environments.

Lightweight and Portable: Rolled up, it’s effortless to transport to far off sites, lowering logistics prices and enabling get admission to to areas with restrained infrastructure.

Key Applications: Concrete Impregnated Fabric in Culverts, Canals, and Pipes

Concrete impregnated cloth is versatile sufficient to clear up a vary of infrastructure challenges, from new building to emergency repairs:

1. Culvert Construction and Rehabilitation

Culverts—critical for directing water below roads or railways—often go through from corrosion, blockages, or structural damage. Concrete impregnated material is used to line current culverts (rehabilitating them barring excavation) or construct new ones. For rehabilitation, crews insert a custom-cut Instant Concrete Mat into the culvert, moist it, and let it harden into a smooth, long lasting liner that stops leaks and resists abrasion. For new construction, the cloth is fashioned over a easy frame, activated with water, and hardened into a light-weight but sturdy culvert that’s quicker to deploy than typical concrete. This minimizes street closures and reduces disruption to traffic.

2. Canal Lining and Erosion Control

Earthen canals lose water to seepage and erode over time, lowering irrigation effectivity and requiring steady maintenance. Concrete impregnated material serves as an best Ditch Lining Material—it’s laid alongside the canal mattress and banks, activated with water, and hardens into an impermeable barrier that prevents seepage and erosion. Unlike inflexible concrete liners, it conforms to the canal’s herbal contour and adapts to minor soil movement, averting cracks. The cloth additionally helps vegetation boom on canal banks (when left partly exposed), improving ecological concord and similarly stabilizing the soil.

3. Pipe Repair and Reinforcement

Underground pipes (for water, sewage, or industrial fluids) are inclined to corrosion, cracks, and root intrusion. Instant Concrete Mat affords a trenchless restore solution: crews wrap the cloth round the broken pipe area (above or under ground), moist it, and let it harden into a inflexible sleeve that reinforces the pipe and stops leaks. This eliminates the want for high priced excavation, decreasing downtime and disruption to landscapes or city areas. For large-diameter pipes, the material can be fashioned into a full liner that’s inserted into the pipe, developing a new, clean indoors that improves go with the flow and extends the pipe’s lifespan.

4. Stormwater Drainage Systems

Stormwater drains and ditches face heavy glide throughout rain events, main to erosion and blockages. Concrete impregnated material traces these drains, developing a durable, clean floor that resists scouring and prevents sediment buildup. As a Ditch Lining Material, it’s mainly high-quality in city stormwater systems, the place house is restrained and fast set up is critical. The fabric’s permeability (when the usage of porous variants) can additionally be adjusted to permit managed infiltration, lowering runoff and easing strain on municipal drainage networks.

Installation Best Practices for Concrete Impregnated Fabric

The simplicity of putting in concrete impregnated material is a key benefit for infrastructure projects. Follow these steps for optimum results:

1. Site PreparationClear the website of debris, rocks, and vegetation

For culverts or pipes, smooth the interior/exterior to do away with dirt, rust, or particles that should stop adhesion. For canals or ditches, grade the floor to create a smooth, even base. For restore projects, patch massive holes or cracks with a quick-setting mortar earlier than making use of the fabric.

2. Measure and Cut the Fabric

Measure the dimensions of the shape (culvert diameter, canal length/width, pipe section) and reduce the concrete impregnated cloth to size, leaving 15–20 cm overlaps at seams for a watertight bond. Use a utility knife or scissors for unique cuts—ensure the material matches snugly round curves or irregular shapes.

3. Position and Activate the Fabric

Place the cloth in the preferred position: line it alongside the canal bed, wrap it round the pipe, or insert it into the culvert. For vertical surfaces (like canal banks), use anchors or transient helps to maintain the material in place. Activate the cloth by using spraying or pouring water evenly over the complete surface—ensure each part is entirely wetted, as dry spots will now not harden properly. Instant Concrete Mat will begin to harden inside 1–2 hours.

4. Finish and Cure

Smooth out any wrinkles or air bubbles in the material earlier than it hardens. For seams, overlap the cloth edges and press them collectively firmly to fuse all through hydration. Allow the cloth to treatment absolutely (typically 24–48 hours) earlier than exposing it to water drift or traffic. For brought protection, observe a concrete sealant to the surface, particularly in harsh chemical environments.

Conclusion: Concrete Impregnated Fabric—The Future of Infrastructure

Concrete impregnated fabric, from Instant Concrete Mat to Ditch Lining Material, is reshaping the infrastructure enterprise by way of imparting a faster, cheaper, and extra long lasting choice to ordinary materials. Its capacity to adapt to various applications—culverts, canals, pipes, and beyond—makes it essential for cutting-edge infrastructure projects.

For engineers, contractors, and municipalities, this fabric isn’t simply a building tool—it’s a answer to the challenges of getting old infrastructure and developing demand for efficient, sustainable development. It reduces costs, minimizes disruption, and extends the lifespan of fundamental assets, making sure infrastructure stays dependable for decades. As cities make bigger and local weather exchange will increase the pressure on water and transportation systems, concrete impregnated cloth will proceed to lead the way in innovative, resilient infrastructure—proving that electricity and effectivity can go hand in hand with pace and sustainability.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province