How Non-Woven Geotextile Cloth Prevents Erosion on Slopes & Construction Sites

Erosion—caused by means of rain, wind, and building activities—poses a extreme risk to slopes, development sites, and surrounding ecosystems. Unchecked erosion can lead to soil loss, structural harm to development projects, sedimentation in water bodies, and elevated upkeep costs. Traditional erosion manage techniques like straw mulch or concrete limitations frequently lack sturdiness or environmental friendliness. Non-Woven Geotextile Cloth has emerged as a versatile and fine solution, revolutionizing erosion prevention with its special properties. This article explores 4 key approaches Non-Woven Geotextile Cloth safeguards slopes and development sites, highlighting why Geotextile products, mainly non woven geotextile fabric, are indispensable for present day erosion management.

1. Superior Material Properties: The Basis of Reliable Erosion Resistance

The erosion prevention functionality of Non-Woven Geotextile Cloth stems from its superior cloth composition and structure. Typically made from polypropylene or polyester fibers, non woven geotextile material is manufactured thru a needle-punching or thermal bonding process, developing a dense, porous, and bendy textile. This special shape endows it with houses especially tailor-made for erosion manipulate scenarios.

First, Non-Woven Geotextile Cloth boasts gorgeous tensile power and durability. Unlike fragile straw mulch that decomposes rapidly or skinny plastic sheets that tear easily, the interlocked fiber shape of non woven geotextile material resists breaking below the stress of going for walks water or wind. It can face up to heavy rainfall (up to 150mm per hour) and robust winds (up to 100km/h) besides dropping integrity, presenting long-term safety for slopes and development sites. Additionally, polypropylene and polyester fibers are resistant to UV radiation, chemical corrosion (from soil vitamins or development chemicals), and organic degradation, making sure a carrier existence of five to 10 years—far longer than usual transient erosion manipulate materials.

Second, the porous nature of Non-Woven Geotextile Cloth balances water permeability and soil retention. While it blocks massive soil particles from being washed away, it approves water to seep thru to the underlying soil. This prevents floor runoff accumulation (a principal motive of slope erosion) and continues soil moisture, growing favorable stipulations for vegetation growth. Unlike impermeable plastic sheets that reason waterlogging and in addition soil instability, Geotextile Cloth achieves a integral stability between erosion prevention and soil health.

2. Physical Protection Mechanisms: Directly Blocking Erosion Factors

Non-Woven Geotextile Cloth prevents erosion thru three core bodily mechanisms, forming a complete defense machine in opposition to exterior erosion factors. These mechanisms work synergistically to guard soil on slopes and building sites.

The first mechanism is floor coverage. When laid on slopes or uncovered development soil, Non-Woven Geotextile Cloth acts as a bodily barrier between the soil and exterior forces. It absorbs the influence of raindrops, which is a fundamental purpose of splash erosion—when raindrops dislodge soil particles and create small craters that speed up runoff. Tests exhibit that laying non woven geotextile material can minimize splash erosion by using over 90% on 30-degree slopes. For development sites, it covers uncovered soil piles, stopping wind erosion and decreasing dirt pollution—a key compliance requirement for many development regulations.

The 2nd mechanism is soil reinforcement. Non-Woven Geotextile Cloth interlocks with soil particles, bettering soil cohesion. On slopes, this reduces the chance of soil slippage by means of distributing the weight of the soil evenly. During construction, it is frequently used in conjunction with backfill materials: when positioned between layers of soil or gravel, it prevents intermixing and reinforces the shape of embankments or keeping walls. Geotextile merchandise in this software can make bigger the shear power of soil by way of 30% to 50%, notably enhancing slope stability.

The 1/3 mechanism is runoff control. By slowing down the pace of floor runoff, Non-Woven Geotextile Cloth reduces the runoff's capacity to lift soil particles. Its porous shape lets in water to infiltrate gradually, minimizing the quantity and speed of runoff. On development sites, this prevents the formation of gullies and reduces sedimentation in close by drains or water bodies—helping contractors keep away from fines for environmental non-compliance.

3. Strong Construction Adaptability: Suitable for Diverse Scenarios

Slopes and building web sites fluctuate broadly in terrain, size, and environmental conditions—from steep mountain slopes to flat development lots, from arid areas to wet areas. Non-Woven Geotextile Cloth stands out for its sturdy adaptability, making it appropriate for nearly all erosion manage scenarios.

First, it is light-weight and convenient to install. A 200g/m² Non-Woven Geotextile Cloth weighs solely 0.2kg per rectangular meter, making it effortless to transport and raise to faraway slope web sites or giant building areas. Installation requires no complicated equipment: people can reduce the cloth to dimension with normal scissors, lay it without delay on the soil surface, and repair it with anchors or gravel. A crew of 2-3 humans can installation over 2000 rectangular meters per day—far quicker than putting in concrete obstacles or stone revetments.

Second, it adapts to complicated terrains. Non-Woven Geotextile Cloth is distinctly flexible, conforming to irregular surfaces such as uneven slopes, curved embankments, or building trenches. For steep slopes (up to 60 degrees), it can be laid in overlapping layers to make certain full insurance barring sliding. In development web sites with pipelines or underground structures, it can be reduce to in shape round obstacles, averting gaps that would lead to localized erosion.

Third, it is like minded with different erosion manage measures. Non-Woven Geotextile Cloth works seamlessly with vegetation-based erosion manipulate (such as hydroseeding). When laid beneath grass seeds or vegetation mats, it protects the seeds from being washed away whilst conserving moisture to promote germination. It additionally enhances challenging buildings like maintaining walls: setting geotextile cloth at the back of the wall prevents soil from seeping via gaps whilst permitting water drainage, extending the wall's provider life.

4. Ecological and Cost Benefits: Sustainable and Economical

In addition to its erosion manipulate effectiveness, Non-Woven Geotextile Cloth presents great ecological and financial advantages, making it a low-priced desire for each non permanent development tasks and long-term slope management.

Ecologically, non woven geotextile cloth is environmentally pleasant and promotes ecosystem recovery. Unlike concrete or plastic sheeting that disrupts soil ecosystems, it is permeable and permits soil organisms to cross freely, keeping soil fertility. Many non woven geotextile material products are made from recycled substances and are biodegradable (for brief applications), lowering environmental impact. By facilitating vegetation growth, it helps repair herbal vegetation cowl on slopes, growing a self-sustaining erosion manipulate device that reduces long-term reliance on synthetic materials.

Economically, Non-Woven Geotextile Cloth provides greatest cost-effectiveness during its existence cycle. In phrases of preliminary investment, it is greater cheap than concrete obstacles (costing solely 20-30% of concrete) and requires much less labor for installation. For a 10,000-square-meter development site, the usage of non woven geotextile material can retailer up to 50% on preliminary erosion manage charges in contrast to ordinary methods.

Long-term price financial savings are even extra significant. Its sturdiness reduces preservation costs—unlike straw mulch that wishes to be changed annually, Non-Woven Geotextile Cloth requires minimal upkeep. It also prevents high-priced damage: by means of stopping erosion, it avoids structural repairs to building tasks (such as basis harm from soil loss) and reduces fines for environmental violations. A learn about of dual carriageway development websites determined that the usage of Geotextile Cloth decreased erosion-related charges through 65% over three years.

Conclusion: Non-Woven Geotextile Cloth—The First Choice for Erosion Prevention

In the face of developing challenges from erosion on slopes and building sites, Non-Woven Geotextile Cloth has established itself as a reliable, adaptable, and most economical solution. Its top-quality cloth houses furnish a strong basis for erosion resistance, whilst its multi-layered bodily safety mechanisms immediately block the root reasons of erosion. Its robust development adaptability ensures it works in various scenarios, and its ecological and financial advantages align with modern-day sustainable improvement goals.

Whether you are managing a steep dual carriageway slope, a residential development site, or a mining reclamation area, Non-Woven Geotextile Cloth provides a complete erosion manage solution. By deciding on fantastic Geotextile products—especially non woven geotextile fabric—you now not solely shield your assignment from erosion however additionally make a contribution to environmental sustainability and long-term fee savings. Invest in Non-Woven Geotextile Cloth nowadays and impenetrable your web site towards erosion risks.

Contact Us

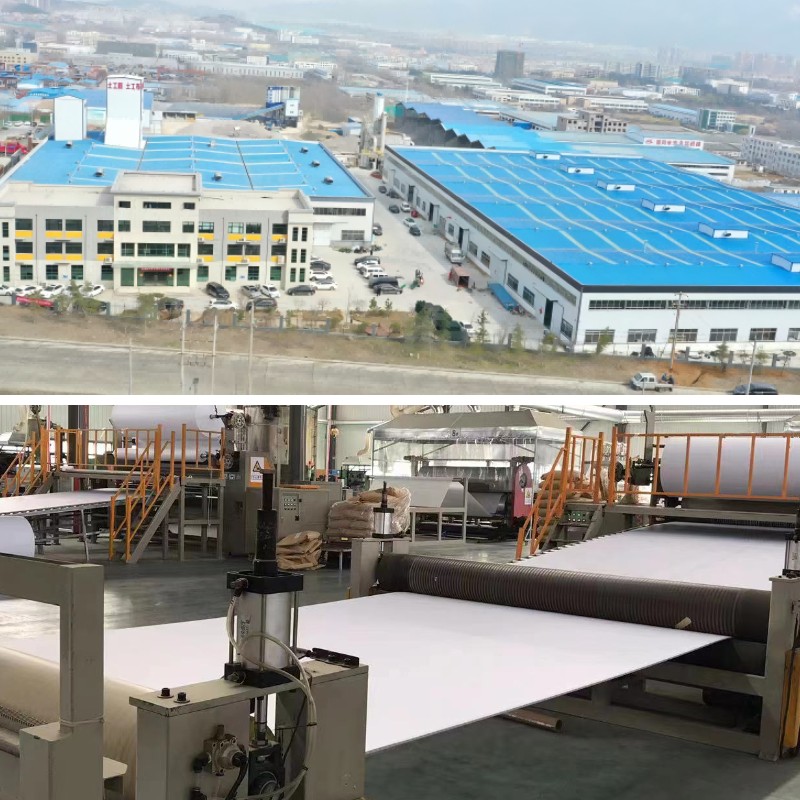

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province