HDPE Geomembrane Specifications Explained: What Contractors & Project Managers Need to Know

For contractors and challenge managers in the development and environmental engineering sectors, choosing and imposing the proper geomembrane is fundamental to mission success. Among the more than a few picks available, HDPE Geomembrane stands out as a pinnacle desire for its magnificent durability, chemical resistance, and versatility. But grasp its specifications—from fabric residences to development standards—can be complex. This information breaks down the key components of HDPE Geomembrane that each enterprise expert wishes to know, making sure your subsequent challenge advantages from most reliable overall performance and long-term reliability.

1. HDPE Geomembrane Material Properties: The Foundation of Performance

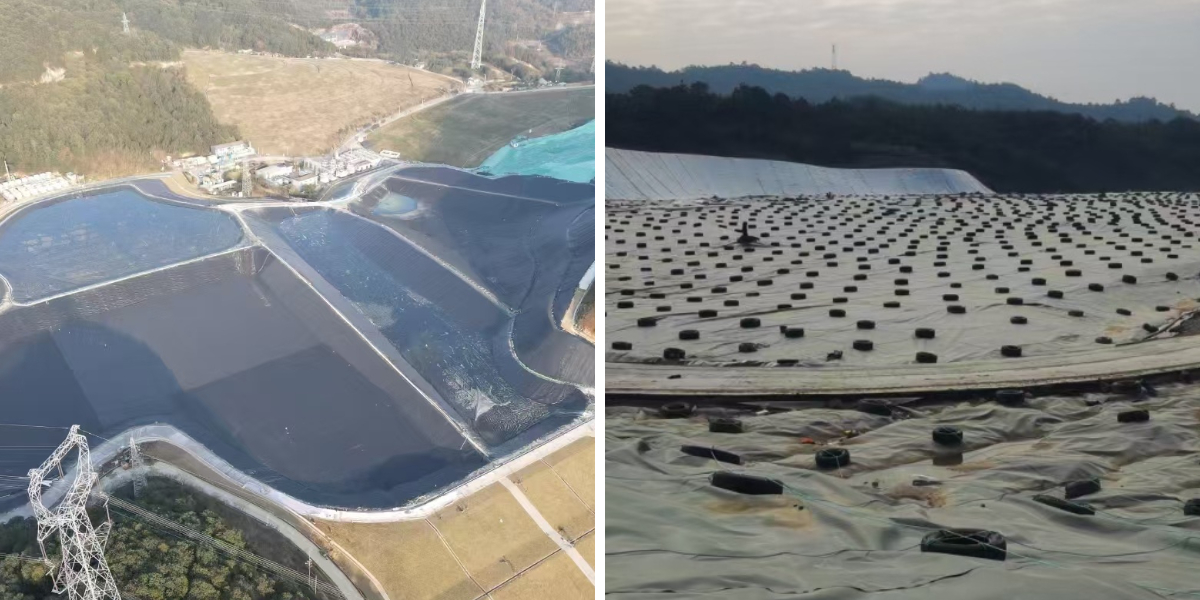

The overall performance of HDPE Geomembrane starts with its core fabric properties, which make it appropriate for a huge vary of applications, from landfill liners to water storage tanks. High-Density Polyethylene (HDPE) is a thermoplastic polymer regarded for its excessive molecular density, which interprets to optimal energy and resistance in contrast to different geomembrane materials.

1.1 Key Material Characteristics

First, HDPE Geomembrane boasts super chemical resistance. It can stand up to publicity to harsh elements such as acids, alkalis, solvents, and industrial waste—making it best for landfill cells, chemical storage facilities, and mining tailings ponds. Unlike low-density polyethylene (LDPE) geomembranes, HDPE’s dense molecular structure prevents chemical penetration, lowering the chance of leaks and environmental contamination.

Second, tensile energy and puncture resistance are standout features. A nice HDPE Geomembrane usually has a tensile energy of 20-30 MPa and an elongation at spoil of 500-600%, permitting it to face up to floor movement, heavy loads, and set up stress except tearing. This is specially essential for tasks in seismic zones or areas with unstable soil conditions, the place geomembrane flexibility is non-negotiable.

UV resistance is every other necessary property. HDPE Geomembrane is regularly formulated with carbon black or different UV stabilizers, enabling it to withstand degradation from extended daylight exposure. This makes it appropriate for outside functions like pond liners, agricultural irrigation systems, and reservoir covers, the place long-term publicity to the factors is inevitable.

Finally, impermeability is non-negotiable for geomembrane applications—and HDPE Geomembrane delivers. With a permeability coefficient of much less than 1×10⁻¹² cm/s, it correctly prevents the migration of beverages or gases, making sure containment integrity for decades. This stage of impermeability is why regulatory our bodies regularly mandate HDPE Geomembrane for imperative environmental projects.

2. HDPE Geomembrane Construction Standards: Ensuring Proper Installation

Even the highest-quality HDPE Geomembrane will fail if hooked up incorrectly. Adhering to strict building requirements is indispensable to maximize overall performance and keep away from luxurious repairs. Contractors and challenge managers should familiarize themselves with enterprise great practices and nearby regulatory requirements.

2.1 Site Preparation and Base Requirements

The first step in HDPE Geomembrane set up is web site preparation. The base have to be smooth, compacted, and free of sharp objects (such as rocks, roots, or debris) that may want to puncture the geomembrane. A geotextile underlay is frequently advocated to furnish an extra layer of protection in opposition to abrasion and puncture. The base must additionally be graded to make sure appropriate drainage, stopping water buildup that ought to stress the geomembrane over time.

2.2 Installation and Welding Protocols

HDPE Geomembrane is generally established in panels, which are welded collectively the use of both warm wedge welding or extrusion welding. Hot wedge welding is perfect for large, flat surfaces, whilst extrusion welding is used for seams, corners, and repairs. Welding parameters—including temperature, pressure, and speed—must be cautiously managed to make sure strong, leak-proof seams. Each weld ought to be examined straight away the usage of non-destructive strategies such as air strain trying out or vacuum container checking out to realize any defects.

2.3 Post-Installation Inspection

After installation, a complete inspection is required to confirm compliance with standards. This consists of visible inspections of the whole geomembrane surface, as properly as damaging trying out of pattern welds to verify tensile strength. Any defects—such as tears, incomplete welds, or punctures—must be repaired without delay the usage of authorised methods. Documentation of the set up and inspection technique is additionally indispensable for regulatory compliance and future maintenance.

3. HDPE Geomembrane Sizing and Selection: Matching Specifications to Project Needs

Selecting the proper HDPE Geomembrane entails greater than simply deciding on a material—it requires matching the product’s specs to the special wishes of your project. Factors such as application, environmental conditions, and regulatory necessities will decide the greatest thickness, grade, and texture of the geomembrane.

3.1 Thickness Selection

HDPE Geomembrane thickness degrees from half mm to three mm, with thicker substances presenting larger power and puncture resistance. For non-critical functions like ornamental ponds or transient containment, a 0.5-1.0 mm thick geomembrane may additionally be sufficient. However, fundamental purposes such as landfill liners, hazardous waste containment, or giant water reservoirs require thicker substances (1.5-3.0 mm) to meet regulatory requirements and make certain long-term durability. Project managers must additionally reflect onconsideration on the chance of mechanical damage—for example, tasks with heavy gear visitors will require thicker geomembrane or extra safety layers.

3.2 Grade and Texture Considerations

HDPE Geomembrane is reachable in exceptional grades, along with virgin HDPE and recycled HDPE. Virgin HDPE is endorsed for integral purposes due to its regular fantastic and performance, whilst recycled HDPE may additionally be appropriate for non-critical tasks the place price is a predominant concern. Texture is some other vital factor: easy HDPE Geomembrane is perfect for purposes requiring effortless cleansing or fluid flow, whilst textured geomembrane (with a difficult surface) affords higher traction for employees and prevents slippage in moist conditions.

3.3 Regulatory Compliance

Before deciding on a HDPE Geomembrane, it’s necessary to take a look at neighborhood and countrywide regulatory requirements. For example, the U.S. Environmental Protection Agency (EPA) has strict requirements for geomembrane used in landfill liners, together with minimal thickness and chemical resistance requirements. Failure to comply with these requirements can end result in task delays, fines, or even criminal liability. Working with a legitimate provider who affords licensed HDPE Geomembrane can assist make certain compliance.

4. HDPE Geomembrane Quality Testing: Verifying Performance Before and After Installation

Quality trying out is a quintessential step in the HDPE Geomembrane lifecycle, from manufacturing to post-installation. It ensures that the product meets specs and will function as predicted in its meant application. Contractors and mission managers must put in force a rigorous checking out protocol to mitigate risk.

4.1 Pre-Installation Testing

Before installation, HDPE Geomembrane rolls have to be inspected for defects such as cracks, holes, or inconsistent thickness. Samples need to additionally be despatched to an impartial laboratory for checking out of key properties, consisting of tensile strength, chemical resistance, and impermeability. This pre-installation checking out verifies that the product meets the required specs and identifies any problems earlier than they influence the project.

4.2 In-Process and Post-Installation Testing

As stated earlier, in-process trying out of welds is necessary to make certain seam integrity. Non-destructive trying out strategies like air stress checking out (which exams for leaks in welds) need to be carried out on each and every weld, whilst unfavourable trying out (such as peel and shear tests) ought to be performed on a pattern of welds to verify strength. Post-installation trying out consists of visible inspections, leak detection surveys (using strategies like electrical leak detection for HDPE Geomembrane), and long-term monitoring to make sure ongoing performance.

Conclusion: Investing in HDPE Geomembrane Excellence

HDPE Geomembrane is a dependable and versatile answer for containment and lining applications, however its success relies upon on grasp and adhering to key specifications. By focusing on fabric properties, building standards, resolution criteria, and best testing, contractors and task managers can make certain that their HDPE Geomembrane set up promises long-term performance, regulatory compliance, and cost-effectiveness. Whether you’re working on a landfill, water reservoir, or industrial containment project, partnering with a relied on dealer and following exceptional practices will assist you maximize the price of your HDPE Geomembrane investment.

Contact Us

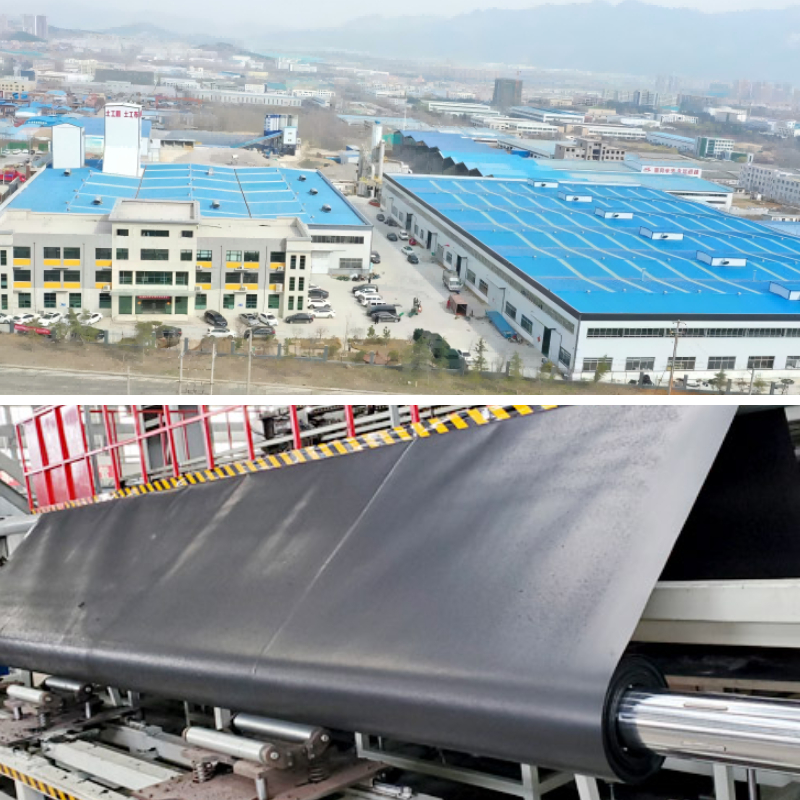

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province