HDPE Geocells: Why Material Quality Impacts Project Durability and Environmental Resistance

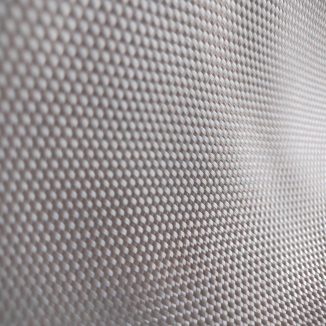

HDPE geocells—honeycomb-shaped high-density polyethylene (HDPE) structures—are crucial for slope stabilization, street construction, and erosion control, thanks to their capacity to lock in soil, gravel,or aggregate. Yet, no longer all hdpe geocell merchandise function equally: cloth first-class is the defining issue in how properly they face up to weather, traffic, and environmental stress. Low-quality geocell leads to untimely cracking, stretching, or failure, derailing tasks and elevating long-term costs. Below, we discover 4 imperative methods HDPE cloth nice shapes assignment success, assisting you make investments in hdpe geocell that supplies lasting sturdiness and environmental resilience.

1. Material Density (HDPE Grade) Determines Load-Bearing Capacity

The load-bearing energy of hdpe geocell hinges on HDPE density, measured in grams per cubic centimeter (g/cm³), normally ranging from 0.941–0.965 g/cm³ for geocell applications. High-density HDPE (0.950+ g/cm³) facets tightly packed polymer chains, making it resistant to stretching and deformation underneath pressure—ideal for high-stress tasks like busy roads, parking lots, or steep slopes the place soil weight exerts regular force. For example, a avenue constructed with high-density geocell can manage every day truck visitors (up to 80,000 lbs) barring cellphone cave in or mixture displacement. In contrast, low-density HDPE (<0.945 g/cm³)—used in low cost hdpe geocell—has looser polymer chains, main to effortless stretching. A low-density geocell in a residential driveway may also sag inside 1–2 years, requiring high priced regrading or replacement.

High-density HDPE additionally provides most useful creep resistance (resistance to sluggish deformation over time), a should for long-term projects. A high-grade hdpe geocell continues its structure for 20+ years, whilst low-density selections deform in 5–7 years. Always confirm HDPE density in producer specs—avoid geocell with unspecified or low-density grades, as they compromise load-bearing reliability.

2. UV Stabilization Prevents Sun-Related Degradation

Most hdpe geocell installations are uncovered to direct sunlight, which breaks down unprotected HDPE by using photo-oxidation. UV stabilization—additives blended into HDPE for the duration of manufacturing—dictates how properly the geocell resists solar damage. Premium hdpe geocell makes use of high-concentration, broad-spectrum UV stabilizers (e.g., hindered amine mild stabilizers, HALS) that soak up or replicate UV rays, retaining polymer integrity. A UV-stabilized geocell in sunny climates (e.g., the Southwest U.S.) retains 90% of its energy after 10 years, with no brittleness or cracking.

Cheap hdpe geocell skips UV components or makes use of low-concentration blends, main to speedy degradation: inside 2–3 years, the fabric turns into brittle, fades, and develops cracks. A cracked geocell can no longer preserve aggregate, inflicting erosion, potholes, or slope failure. To verify UV protection, seem for geocell with third-party certifications (e.g., ASTM D4355, which checks UV resistance for geosynthetics) or producer ensures (e.g., “15-year UV warranty”). Avoid products claiming “UV-resistant” besides proof—this indicators insufficient stabilization.

3. Chemical Resistance Shields Against Harsh Substances

Hdpe geocell regularly contacts chemicals: de-icing salts on roads, fertilizers in landscaping, or industrial runoff in development zones. Material quality—specifically whether or not the HDPE is virgin or recycled, and if it consists of chemical stabilizers—determines resistance to these substances. High-quality hdpe geocell makes use of virgin HDPE (no contaminants) with introduced chemical stabilizers; virgin HDPE is inherently resistant to most acids, bases, salts, and natural solvents. For instance, a geocell in a street dealt with with de-icing salt won’t swell, discolor, or weaken over time, and one in agricultural settings resists fertilizer runoff to keep away from breakdown.

Low-quality hdpe geocell makes use of recycled HDPE (which may additionally incorporate impurities) or blends with plastics like PVC (prone to chemical damage). Recycled HDPE has inconsistent resistance—exposure to salt or fertilizer can make it soften, leak, or dissolve. A chemically broken geocell in a parking lot can also peel or separate, requiring full alternative in 4–5 years. For initiatives with chemical exposure, ask producers for compatibility take a look at reviews (e.g., with sodium chloride or ammonium nitrate) and select hdpe geocell rated for your site’s particular chemicals.

4. Thickness and Wall Strength Ensure Impact and Tear Resistance

Hdpe geocell faces bodily stress: heavy tools throughout installation, sharp rocks in soil, or unintended influences from development vehicles. Material thickness (measured in mils or millimeters) and wall power without delay have an effect on its capability to face up to tears, punctures, and impacts. Premium hdpe geocell has wall thicknesses of 10–15 mils (0.25–0.38 mm) or more, with strengthened seams (heat-welded or stitched with heavy-duty thread). Thick partitions withstand punctures from sharp rocks or tools tires—even a shovel or wheelbarrow have an impact on won’t tear the material—while strengthened seams forestall splitting at joints, a frequent failure factor for low-quality geocell.

Cheap hdpe geocell has partitions thinner than eight mils (0.20 mm) with no seam reinforcement. Thin partitions puncture easily—small rocks in soil create holes that let combination escape—while unreinforced seams cut up underneath minimal stress. A geocell with susceptible seams in a slope might also separate all through heavy rain, triggering soil erosion and collapse. To check wall strength, take a look at tensile energy specs (premium geocell has 200+ psi) and take a look at samples: press a fingernail firmly into the wall—high-quality HDPE won’t dent or tear, whilst low-quality cloth creases or punctures.

Final Tips: Choosing High-Quality HDPE Geocell

Prioritize virgin HDPE over recycled or blended plastics—virgin fabric ensures steady electricity and resistance. Look for ASTM, ISO, or GRI (Geosynthetic Research Institute) certifications, which verify the geocell meets enterprise requirements for density, UV resistance, and strength. Opt for producers providing 10–20 12 months warranties; brief warranties (5 years or less) point out low-quality material. Request samples to check flexibility (should bend barring cracking), UV resistance (expose to daylight for a week—no brittleness), and puncture resistance (no holes from sharp objects).

By focusing on fabric quality—density, UV stabilization, chemical resistance, and wall strength—you’ll pick hdpe geocell that withstands the elements, handles loads, and promises long-term value. Whether constructing a road, stabilizing a slope, or controlling erosion, gorgeous geocell is the foundation of a durable, profitable project.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province