The Science of Durability: How Geomembranes Resist Oxidation, UV Degradation, and Chemical Attack

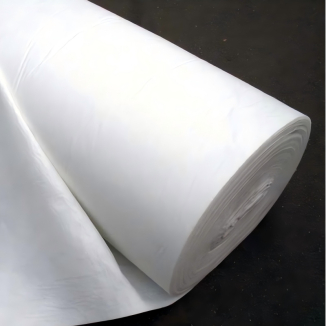

In the world of containment and environmental protection, few supplies are as integral as the geomembrane. These synthetic liners act as impermeable barriers, safeguarding water supplies, defending soil from contamination, and securing waste in landfills. But to feature these fundamental roles for decades, a geomembrane want to be specially durable. Its fantastic enemies are commonly invisible: the sun's relentless rays, atmospheric oxygen, and aggressive chemicals. So, how does a cutting-edge geomembrane, in particular an HDPE geomembrane, acquire such long-lasting performance? The reply lies in a modern-day science of stabilization.

Understanding the Geomembrane's Achilles' Heel: Polymer Degradation

At its core, a geomembrane is a giant polymer molecule—a prolonged chain of repeating units. In their pure form, these polymers are inclined to environmental stressors. The quintessential mechanisms of degradation are:

Oxidation: A response with oxygen that breaks the polymer chains, making them brittle.

UV Degradation: Ultraviolet radiation from daylight hours affords the energy to sever chemical bonds.

Chemical Attack: Certain substances can swell, dissolve, or stress-crack the polymer matrix.

Without protection, a geomembrane uncovered to these elements would rapidly fail. This is the vicinity ultimate engineering and additive technological understanding come into play.

The Fortified Formulation of HDPE Geomembrane

High-Density Polyethylene (HDPE) is one of the most notably used polymers for geomebranes due to its awesome chemical resistance and mechanical properties. However, the raw HDPE polymer is now no longer inherently immune to degradation. The top notch sturdiness of a achieved geomembrane in HDPE is a quit end result of a cautiously engineered recipe that consists of base resin and a suite of defensive additives. These elements are the secret to its longevity.

Battling the Invisible Enemy: Resistance to Oxidation

Oxidation, or thermal-oxidative degradation, is a chain response that can be initiated by way of way of heat, mechanical stress, or catalyst residues. It slowly erodes the material's flexibility and strength.

The Defense Mechanism: Antioxidants (AOs)

To combat this, producers compound antioxidants at as soon as into the HDPE resin before than the geomembrane is sheet-extruded. These factors work in two key ways:

1. Chain Breakers: These AOs donate a hydrogen atom to the free radicals usual at some stage in the preliminary stage of oxidation, efficiently stopping the chain response in its tracks.

2. Hydroperoxide Decomposers: These AOs convert hydroperoxides (unstable intermediates in the oxidation process) into stable, non-radical products.

By incorporating a sturdy bundle of primary and secondary antioxidants, a fantastic HDPE geomembrane is geared up to face up to oxidation for decades, even when buried in environments with prolonged temperatures. This long-term stability is a cornerstone of the material's reliability.

Shielding from the Sun: Combating UV Degradation

When a geomembrane is uncovered to sunlight, each for the duration of set up or in uncovered applications, UV radiation will end up a significant threat. Photons from UV moderate have adequate power to smash polymer bonds, major to ground cracking, chalking, and loss of tensile strength.

The Defense Mechanism: Carbon Black

The most best and regular protect in the direction of UV degradation is carbon black. This is now now not sincerely a handy dye; it is a in particular engineered, finely divided shape of carbon that serves a couple of defending functions:

UV Absorption: Carbon black absorbs the unfavourable UV radiation during the entire spectrum, altering it into negligible portions of heat.

Free Radical Quenching: It acts as a giant scavenger, trapping the free radicals generated by way of capability of any UV slight that penetrates the surface.

Physical Barrier: The particles create a bodily neighborhood that hinders the diffusion of oxygen, imparting an extra layer in opposition to oxidation.

A proper formulated geomembrane will incorporate a immoderate grade of carbon black, usually 2-3%, uniformly dispersed at some stage in the sheet. This ensures that even if the ground is scratched or abraded, the underlying material stays protected. This makes a carbon-stabilized HDPE geomembrane fantastic for uncovered functions like reservoirs and canal linings.

Standing Strong Against Corrosives: Resistance to Chemical Attack

Perhaps the most celebrated property of an HDPE geomembrane is its extremely good chemical resistance. From acidic mine leachate to industrial waste solvents, it affords a resilient barrier.

The Defense Mechanism: Inert Molecular Structure

The resistance is no longer in general from factors alternatively from the intrinsic nature of the HDPE polymer itself.

Non-Polarity: HDPE is a non-polar molecule, that potential it has no awesome or horrific prices on its surface. This makes it incredibly resistant to polar chemical compounds like acids, alkalis, and salts, which are time-honored in many waste streams.

High Crystallinity: The polymer chains in HDPE are tightly packed in crystalline regions, growing a dense, tortuous direction that most chemical fluids can not without difficulty penetrate.

Lack of Solubility Parameters: Most aggressive chemical resources cannot dissolve HDPE due to the truth their solubility parameters do no longer match, stopping swelling and disintegration.

This inherent inertness is why a geomembrane in HDPE is the material of desire for hazardous waste landfills, mining operations, and wastewater treatment lagoons. It continues its integrity in the face of a extensive array of corrosive substances.

The Synergy of Protection: A System Built to Last

The actual genius of a contemporary geomembrane lies in the synergy of its defending systems. The carbon black that shields from UV slight moreover reinforces the struggle in opposition to oxidation. The antioxidants that prevent thermal degradation make positive the polymer's crystalline structure stays intact, bolstering its chemical resistance. This multi-faceted safety is what lets in a extraordinarily precise HDPE geomembrane to have a company existence that can lengthen previous 50 years, even in harsh environments.

Conclusion: An Engineered Solution for Long-Term Performance

The sturdiness of a geomembrane is now no longer an accident. It is the direct give up end result of modern day polymer science and specific engineering. By hold close and proactively defending toward the threats of oxidation, UV radiation, and chemical attack, producers create a product that is a lengthy way greater than the sum of its parts. Whether you are specifying a lining device for a necessary containment project or really searching for to apprehend the science defending our environment, recognizing the science in the returned of the geomembrane's resilience is key. When you select a suitable formulated HDPE geomembrane, you are investing in a proven, long-term barrier engineered to stand the take a look at of time and the elements.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province