Case Study: How Geocell Reinforced a Highway Construction Project

In the world of infrastructure development, toll road development frequently faces difficult challenges—from unstable soil stipulations to strict sturdiness requirements. For one regional motorway enlargement challenge in a suburban area, engineers became to geocell science to overcome these hurdles, turning in a cost-effective, long-lasting solution. This case find out about breaks down how geocell avenue systems, paired with specialised versions like geocell silknet and perforated geocell, modified a high-risk task into a success story.

1. Project Background: The Challenges of Suburban Highway Expansion

The mission aimed to widen a 12-kilometer rural toll road to a four-lane road, connecting two developing towns. While the purpose was once straightforward, the website introduced massive obstacles:

Unstable Subgrade Soil: The area’s clay-rich soil retained moisture easily, main to compaction troubles and doable avenue agreement over time. During wet seasons, the soil grew to become soft, growing the chance of potholes and structural damage.

Heavy Traffic Demands: The accelerated motorway would want to assist every day commuter traffic, as properly as occasional heavy vehicles transporting agricultural goods. This required a avenue base succesful of withstanding excessive masses barring deforming.

Tight Timeline & Budget: Local authorities set a 10-month closing date to decrease disruption to current traffic, and the challenge had restrained cash for costly soil replacement.

Initial plans to use typical gravel layers on my own had been deemed insufficient—engineers warned that the soil’s bad steadiness would lead to regular upkeep inside 3–5 years. It used to be clear: a strengthened answer was once needed, and geocell science emerged as the pinnacle choice.

2. Why Geocell Technology? The Science Behind the Solution

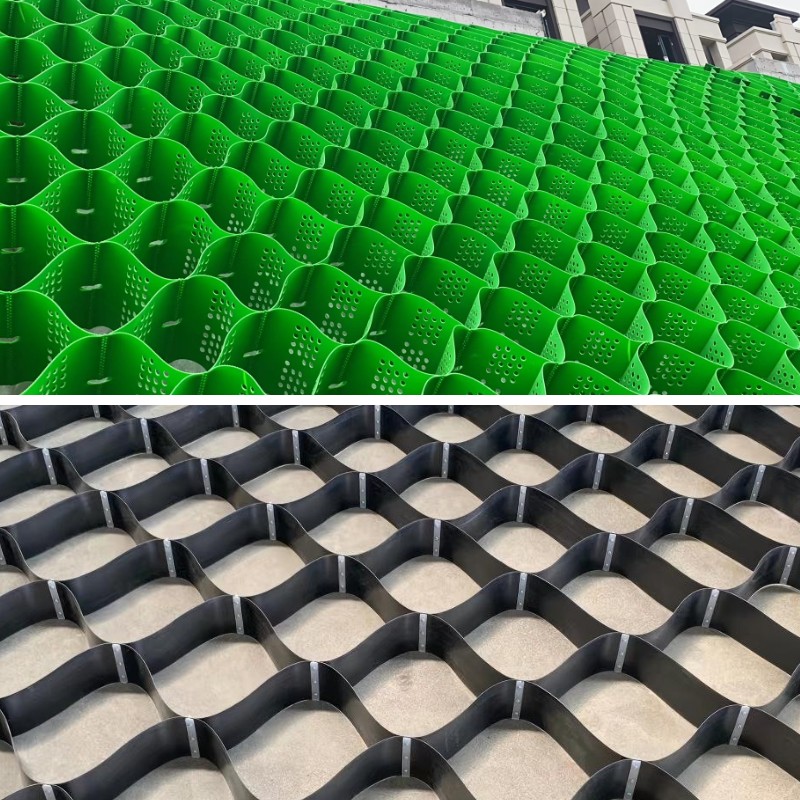

Before diving into implementation, it’s necessary to apprehend why geocells stood out. Geocells are three-dimensional, honeycomb-like constructions made from high-density polyethylene (HDPE) or comparable long lasting materials. When multiplied and crammed with combination (like gravel or beaten stone), they create a rigid, interlocked base that distributes weight evenly—solving the core problem of unstable soil.

For this project, three key geocell variations had been chosen to tackle precise needs:

Geocell Road Systems: The most important answer for the highway’s base layer. These geocells have been designed to manage heavy loads, stopping soil displacement and decreasing settlement.

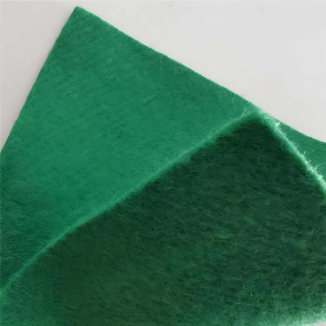

Geocell Silknet: A lightweight, high-tensile variant used in the subgrade layer. Its fine, net-like shape brought greater reinforcement to the clay soil, enhancing drainage and stopping erosion.

Perforated Geocell: Installed in areas inclined to waterlogging (e.g., low-lying sections of the highway). The perforations allowed extra moisture to drain away from the avenue base, preserving the soil secure even at some stage in heavy rains.

Together, these variations created a multi-layered reinforcement device that addressed the project’s largest risks: soil instability, bad drainage, and heavy site visitors loads.

3. Implementation Process: From Site Prep to Geocell Installation

The venture crew accompanied a strict, phased strategy to make certain the geocell machine was once established correctly—critical for maximizing its performance. Here’s a step-by-step breakdown:

3.1 Site Preparation & Soil Testing

First, the current avenue floor was once removed, and the subgrade soil used to be excavated to a depth of 60 centimeters. Engineers performed significant soil assessments to verify moisture stages and compaction rates, adjusting the geocell diagram to in shape the site’s precise conditions. For example, in areas with greater clay content, the geocell silknet layer used to be thickened to 10 centimeters (up from the fashionable eight cm) to enhance reinforcement.

3.2 Installing the Geocell Silknet Layer

The geocell silknet used to be laid first, without delay on the excavated subgrade. The cloth used to be unrolled and secured to the soil the use of metal stakes, making sure it lay flat and tight (no wrinkles, which should decrease effectiveness). The silknet’s bendy but sturdy structure acted as a “barrier” between the clay soil and the top geocell layers, stopping best soil particles from mixing with the combination and clogging drainage paths.

3.3 Laying the Perforated Geocell for Drainage

Next, perforated geocell panels had been extended and positioned on pinnacle of the silknet layer. These panels have been two meters vast and 5 meters long, with 10-millimeter diameter perforations spaced 15 centimeters apart. The crew aligned the perforations to face downward, permitting water to seep via the geocell and into a community of French drains set up alongside the highway’s edges. This step used to be imperative for preserving the street base dry—one of the fundamental reasons of untimely avenue failure.

3.4 Building the Geocell Road Base

The closing layer was once the geocell avenue system: larger, heavy-duty geocell panels (3 meters wide, 6 meters long) with a phone peak of 15 centimeters. These had been extended and linked to structure a non-stop mat over the perforated geocell layer. The cells had been then crammed with beaten limestone mixture (size 20–40 mm), which used to be compacted the usage of a vibratory curler to make sure most density. The geocell’s honeycomb shape locked the mixture in place, growing a inflexible base that should distribute visitors hundreds throughout a wider area—reducing strain on the underlying soil.

3.5 Final Paving & Quality Checks

Once the geocell layers had been established and compacted, a 10-centimeter asphalt floor used to be laid on top. The group performed post-installation tests, consisting of load-bearing exams (using simulated truck weights) and drainage checks (simulating heavy rain). The outcomes had been promising: the avenue base ought to face up to 30% greater load than the authentic design, and drainage costs have been 50% greater than expected.

4. Project Results: Durability, Cost Savings, and Long-Term Benefits

Six months after the toll road opened, the assignment crew carried out a follow-up assessment—and the consequences verified that geocell technological know-how had delivered on its promises. Here’s what they found:

4.1 Improved Durability & Reduced Maintenance

The geocell avenue base confirmed no signs and symptoms of contract or deformation, even in high-traffic areas. Sections with perforated geocell remained dry at some point of heavy rains, with no waterlogging or erosion. The geocell silknet layer had efficiently stabilized the clay soil, stopping the formation of potholes or cracks in the asphalt. Local authorities estimated that renovation prices would be decreased through 40% over the subsequent 10 years—compared to the usual gravel base, which would have required widespread repairs.

4.2 On-Time & On-Budget Delivery

Thanks to the effectivity of geocell set up (the device was once laid 20% quicker than standard soil replacement), the assignment used to be done two weeks beforehand of schedule. The use of geocells additionally decreased the quantity of combination wanted by way of 15% (since the cells held the fabric extra efficiently), slicing fabric expenses by means of about 10%. This was once a important win for the neighborhood government, which had confronted strain to preserve fees low.

4.3 Environmental Benefits

Geocell technological know-how additionally had surprising environmental advantages. By fending off full soil substitute (which would have required excavating and disposing of heaps of lots of clay), the assignment decreased carbon emissions by way of 25%. The perforated geocell’s drainage skills additionally decreased runoff into close by farmland, defending nearby ecosystems.

5. Key Takeaways: Why Geocells Are a Game-Changer for Highway Projects

This case learn about highlights three crucial motives why geocell avenue systems—paired with geocell silknet and perforated geocell—are turning into the go-to answer for toll road construction:

Targeted Problem-Solving: Different geocell variations tackle unique challenges (e.g., drainage with perforated geocells, soil stabilization with silknet), making them versatile for various web site conditions.

Cost-Effectiveness: Geocells decrease fabric usage, velocity up installation, and decrease long-term protection costs—delivering cost for tight budgets.

Durability: By distributing masses evenly and enhancing drainage, geocells lengthen a highway’s lifespan, decreasing the want for widely wide-spread repairs.

For engineers and venture managers going through unstable soil, heavy traffic, or tight deadlines, geocell science provides a proven, dependable solution. As this case find out about shows, investing in geocells isn’t simply a non permanent fix—it’s a long-term funding in a highway’s overall performance and sustainability.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province