Geotextile Cloth for Septic Systems: Filtration & Soil Separation Requirements

Septic structures are indispensable factors of on-site wastewater treatment, making sure the protected disposal and purification of family sewage in areas besides get right of entry to to municipal sewer lines. The effectivity and durability of a septic machine closely rely on the overall performance of its filtration and soil separation components. Geotextile cloth, a permeable artificial fabric, has come to be an fundamental cloth in septic machine layout and installation, thanks to its superb filtration, soil separation, and stabilization capabilities. Fabric geotextile now not solely enhances the system’s wastewater remedy effectivity however additionally protects in opposition to soil erosion and structural degradation. This article explores the indispensable position of geotextile fabric in septic systems, focusing on filtration requirements, soil separation standards, and the significance of geotextile soil stabilization—providing realistic insights for homeowners, contractors, and wastewater professionals.

1. Why Geotextile Cloth Is Essential for Septic System Performance

Septic structures count on a refined balance between soil permeability and contaminant filtration to deal with wastewater effectively. Without ideal filtration and soil separation, solids from sewage can clog soil pores, lowering the system’s capacity to soak up and deal with effluent. This can lead to machine failure, groundwater contamination, and high priced repairs. Geotextile fabric addresses these challenges with the aid of appearing as a barrier that separates sewage solids from the surrounding soil whilst permitting dealt with effluent to bypass through. Its special porous shape and long lasting cloth composition make it perfect for septic gadget applications, the place it should face up to regular moisture, organic activity, and soil pressure.

Fabric geotextile affords numerous key benefits over typical filtration substances (such as straw, gravel, or herbal fabrics) in septic systems. Unlike natural substances that decompose over time, geotextile fabric is resistant to microbial degradation, UV exposure, and chemical corrosion—ensuring long-term overall performance (up to 20-30 years with ideal installation). Additionally, geotextile soil stabilization houses assist hold the structural integrity of septic gadget components, such as drain fields and distribution boxes, by means of stopping soil displacement and erosion. For example, in drain subject installations, geotextile fabric positioned between gravel and soil prevents first-class soil particles from migrating into the gravel layer, which would in any other case clog the drain strains and limit effluent distribution efficiency.

2. Filtration Requirements for Geotextile Cloth in Septic Systems

Filtration is the fundamental feature of geotextile fabric in septic systems, as it prevents suspended solids from coming into the soil absorption area. To make sure advantageous filtration, geotextile material should meet particular overall performance requirements, along with pore size, permeability, and strength. These necessities are ruled through enterprise requirements (such as ASTM D4751 for geotextile specifications) and neighborhood wastewater regulations, which differ based totally on soil type, septic device design, and wastewater volume.

2.1 Pore Size Selection: Balancing Filtration and Permeability

The pore measurement of geotextile material is a essential aspect in septic machine filtration. It have to be small ample to maintain suspended solids (typically 0.075mm to 2mm in sewage) however giant adequate to permit dealt with effluent to skip thru barring immoderate stress buildup. The superb opening measurement (EOS) of the geotextile, measured the usage of ASTM D4751, is the key parameter for pore dimension selection. For most septic systems, geotextile fabric with an EOS between 0.1mm and 0.5mm is recommended. This vary ensures that excellent soil particles and sewage solids are retained, whilst keeping enough permeability (measured as Darcy’s coefficient) to stop effluent backup.

Fabric geotextile with a too-small EOS can grow to be clogged quickly, lowering the system’s filtration capability and main to effluent ponding. Conversely, a too-large EOS fails to keep solids, permitting them to migrate into the soil and clog the absorption area. For example, in sandy soils (which have large pore sizes), a geotextile fabric with a barely larger EOS (0.3-0.5mm) is suitable, whilst in clay soils (fine-grained), a smaller EOS (0.1-0.3mm) is required to stop soil particle migration. Geotextile soil stabilization additionally performs a function here, as a top chosen geotextile continues its pore shape underneath soil pressure, making sure regular filtration overall performance over time.

2.2 Permeability and Flow Rate Standards

Permeability is any other integral filtration requirement for geotextile fabric in septic systems. The geotextile ought to have a permeability price equal to or larger than the surrounding soil to keep away from limiting effluent flow. ASTM D4491 specifies the wellknown check approach for measuring geotextile permeability, with minimal permeability values ranging from 1x10⁻³ cm/s to 1x10⁻¹ cm/s for septic machine applications. This ensures that effluent flows freely thru the geotextile into the soil absorption area, stopping hydraulic overload and gadget failure.

In addition to permeability, the geotextile’s glide charge (measured as liters per minute per rectangular meter) have to be ample to manage the septic system’s day by day wastewater output. For a ordinary residential septic gadget (processing 200-400 gallons of wastewater per day), geotextile fabric with a go with the flow fee of at least five L/min/m² is recommended. Contractors need to additionally think about the geotextile’s thickness and weight, as these elements have an effect on each permeability and durability. Heavier geotextiles (200-400 g/m²) are extra long lasting however may also have barely decrease permeability, so a stability should be struck based totally on the system’s precise needs.

3. Soil Separation Requirements: Protecting Septic System Integrity

Soil separation is any other key feature of geotextile material in septic systems, involving the separation of distinct soil layers and the prevention of soil mixing with gravel or different combination materials. Proper soil separation ensures that the septic system’s structural factors (such as drain lines, gravel beds, and distribution boxes) continue to be purposeful and free from clogging. Geotextile material acts as a barrier between the soil and mixture layers, stopping satisfactory soil particles from coming into the mixture and lowering the chance of soil erosion.

3.1 Layer Separation in Drain Fields and Gravel Beds

In septic drain area installations, geotextile material is generally positioned between the native soil and the gravel mattress that surrounds the drain lines. This separation prevents quality soil particles from migrating into the gravel, which would clog the areas between gravel particles and avert effluent flow. The geotextile should be established in full contact with the soil, with no wrinkles or gaps, to make sure whole separation. Additionally, the geotextile must prolong past the gravel mattress via at least 30 cm to stop soil from getting into the edges of the system.

Fabric geotextile is additionally used to separate exclusive soil layers in septic machine trenches. For example, in areas with layered soils (e.g., topsoil over clay or sand), geotextile fabric prevents the mixing of these layers, which ought to alter the soil’s permeability and limit remedy efficiency. Geotextile soil stabilization in addition enhances layer separation with the aid of supplying tensile energy that resists soil movement, even in areas with excessive groundwater tables or soil settlement.

3.2 Strength and Durability Requirements for Soil Separation

To efficaciously operate soil separation, geotextile fabric should meet particular power and sturdiness requirements. The geotextile should have ample tensile energy (measured as kN/m) to stand up to soil pressure, set up stresses, and long-term environmental conditions. ASTM D4632 specifies the widespread take a look at technique for geotextile tensile strength, with minimal values of 5-10 kN/m for septic gadget applications. This ensures that the geotextile does now not tear or stretch excessively throughout set up or use.

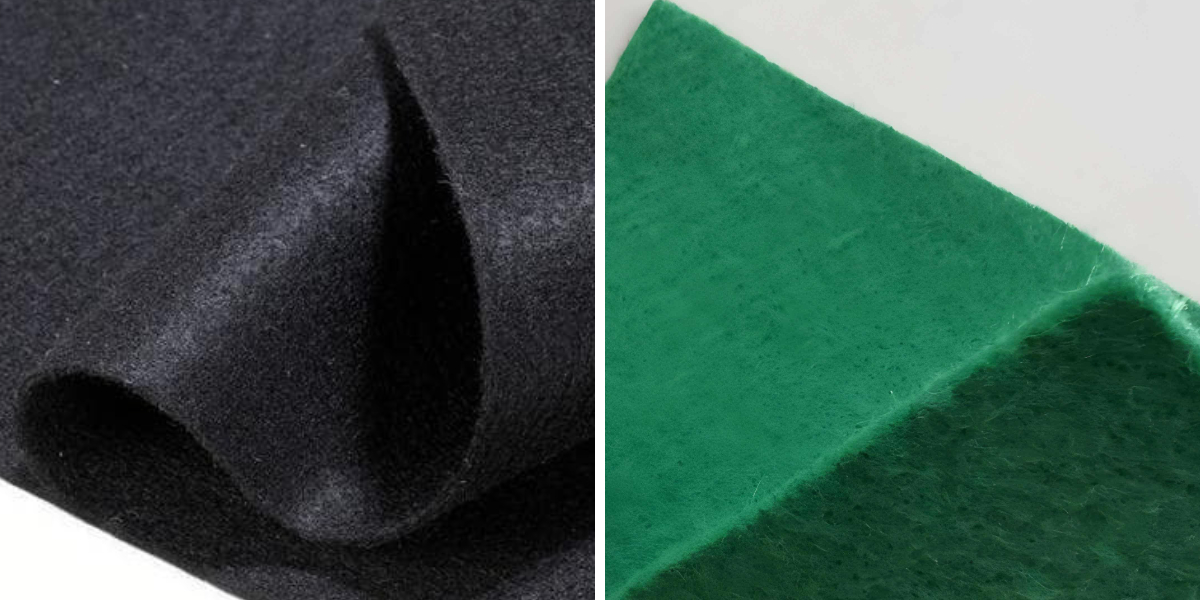

Durability is additionally critical, as geotextile fabric in septic structures is uncovered to regular moisture, microbial activity, and probably harsh chemical substances (such as ammonia and natural acids from sewage). Geotextile fabric made from polypropylene or polyester is recommended, as these substances are resistant to microbial degradation and chemical corrosion. Additionally, UV stabilization is crucial for geotextiles established in uncovered areas (such as the pinnacle of drain fields), as UV radiation can weaken the fabric over time. Most material geotextile merchandise for septic structures consist of UV stabilizers to make sure a carrier lifestyles of 20 years or more.

4. Geotextile Cloth Selection and Installation Best Practices for Septic Systems

Proper choice and set up of geotextile material are fundamental to making sure its effectiveness in septic systems. Homeowners and contractors should reflect onconsideration on soil type, septic machine design, and neighborhood guidelines when deciding on a geotextile product. Additionally, following great practices for set up ensures that the geotextile meets filtration and soil separation necessities and keeps its overall performance over time.

When deciding on geotextile cloth, begin by way of conducting a soil check to decide soil type, particle dimension distribution, and permeability. This records helps decide the terrific EOS, permeability, and power requirements. Choose a cloth geotextile that meets ASTM requirements and is licensed for septic gadget use. Avoid low-quality geotextiles (such as non-woven fabric with low weight or bad strength), as these may additionally fail upfront and lead to gadget problems.

For installation, put together the website online by means of leveling and compacting the soil to dispose of rocks, roots, and different sharp objects that should puncture the geotextile. Lay the geotextile fabric in a single layer, with overlaps of at least 30 cm between adjoining sheets to make sure entire coverage. Secure the geotextile with stakes or sandbags to forestall motion all through gravel placement. When putting in gravel or different aggregates, use a mild gear load to keep away from unfavourable the geotextile. Finally, behavior a post-installation inspection to make certain the geotextile is intact, suitable overlapped, and in full contact with the soil.

Conclusion: Investing in Quality Geotextile Cloth for Long-Lasting Septic Systems

Geotextile material performs a critical function in preserving the efficiency, integrity, and sturdiness of septic systems. By assembly strict filtration and soil separation requirements, geotextile material prevents clogging, protects towards soil erosion, and enhances geotextile soil stabilization. Fabric geotextile, with its durable, permeable, and corrosion-resistant properties, is the perfect cloth for these applications, making sure long-term overall performance and decreasing the danger of expensive gadget failures.

When choosing and putting in geotextile material for septic systems, it is crucial to comply with enterprise requirements and first-rate practices, thinking about soil type, device design, and nearby regulations. By investing in fantastic geotextile material and suited installation, house owners and contractors can make sure that their septic structures function successfully for decades, defending groundwater first-class and the environment. As the demand for dependable on-site wastewater cure grows, geotextile fabric will proceed to be a cornerstone of sustainable septic machine design.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province