Port and Harbor Dredging: Using Geotubes to Handle Contaminated Sediments

The Critical Challenge of Modern Dredging

Ports and harbors are the lifeblood of world trade, however their ongoing performance relies upon on normal dredging. This system eliminates amassed sediments to keep protected navigation depths. However, a great modern-day assignment lies no longer simply in the extent of this material, however in its quality. Decades of industrial undertaking regularly depart these sediments contaminated with heavy metals, hydrocarbons, and different pollutants. Traditional disposal methods, like open-water dumping or restrained disposal facilities, are more and more restrained due to stringent environmental policies and sustainability goals. This has created an pressing want for a cost-effective, efficient, and environmentally sound solution. Enter geotube dewatering technology—a technique that is revolutionizing how the maritime enterprise manages contaminated dredged materials.

What Are Geotubes? The Core Technology Explained

Geotubes, regularly referred to as Large Dewatering Bags or Sludge Filter Bags, are engineered containers made from high-strength, permeable geotextile fabrics. Designed to act as huge dewatering units, they feature through containing slurry—in this case, contaminated dredged sediment blended with water. The cloth acts as a selective filter: it lets in smooth water to drain out below gravity or with moderate pumping assistance, whilst conserving the strong soil particles and, crucially, the contaminants certain to them. This easy but fairly superb mechanical separation system is the cornerstone of the Sludge Bag Dewatering System. The geotubes' strong building permits them to be crammed to giant sizes, developing brief or everlasting containment buildings that dramatically limit the quantity of waste for closing handling.

The Step-by-Step Process: From Sediment to Stable Containment

Implementing a geotube answer for contaminated dredge fabric is a systematic and environment friendly process.

1. Site Preparation and Geotube Deployment: The location the place dewatering will show up is prepared, regularly with a lining gadget to seize any doable leachate. The geotubes, which are delivered flat, are placed and anchored. Their placement is strategic, frequently at once on-site or at a close by specific dewatering facility, minimizing sediment transport.

2. Dredging and Pumping: The contaminated sediment is dredged the use of preferred techniques (e.g., hydraulic dredging) and pumped as a slurry without delay into the geotextile containers. Chemical flocculants can be brought to the slurry movement to motive first-class particles to clump together, accelerating the dewatering system and enhancing water readability in the effluent.

3. Dewatering and Consolidation: This is the essential phase. As the Sludge Bag Dewatering System is filled, water starts offevolved to seep via the fabric's micro-pores. Over weeks and months, the solids are retained inside the Large Dewatering Bags, whilst the extent reduces significantly—often by way of 50-80%. The last solids consolidate into a stable, stackable material.

4. Water Management and Treatment: The effluent water is accumulated and, if necessary, dealt with earlier than being discharged, making sure compliance with all environmental standards. This closed-loop water administration is a key environmental benefit.

5. Final Disposition: Once wholly dewatered, the solidified fabric inside the geotubes can be capped with soil and vegetated for on-site containment, or the tubes can be eliminated for impenetrable landfill disposal. The drastic extent discount makes remaining disposal a ways extra inexpensive and logistically feasible.

Key Advantages Over Traditional Disposal Methods

The use of Sludge Filter Bags for contaminated sediment administration affords compelling advantages for port authorities, contractors, and the environment.

Environmental Compliance and Safety: Geotubes furnish a utterly enclosed remedy system. Contaminants are securely locked inside the cloth matrix, doing away with the hazard of seepage or leaching into surrounding soil and groundwater for the duration of the dewatering phase. This containment extensively reduces environmental liability.

Significant Cost Reduction: By lowering the quantity of cloth that requires pricey transport and hazardous waste landfill space, the Sludge Bag Dewatering System affords large value savings. It additionally eliminates the want for setting up large, everlasting settling ponds.

Operational Flexibility and Efficiency: Large Dewatering Bags can be deployed in quite a number locations, even on restricted sites. The device is scalable and can run continually alongside dredging operations, accelerating venture timelines. The simplicity of the science reduces mechanical complexity and operational downtime.

Sustainable Outcome: Geotubes facilitate the doable for really useful reuse of dewatered sediments. Once contaminants are stabilized and tested, the ensuing soil-like fabric can also be appropriate for landfill cover, web page reclamation, or different non-sensitive applications, contributing to a round financial system model.

Applications in Port and Harbor Scenarios

This science is pretty versatile for maritime applications:

Maintenance Dredging in Contaminated Berths: Regularly cleansing slips and berths the place historic pollution is present.

New Construction in Brownfield Sites: Preparing contaminated seabeds for new port infrastructure.

Emergency Spill Response: Containing and dewatering sediments impacted through unexpected chemical or oil spills.

Capping Underwater Contaminated Sites: Using dewatered and solidified geotube devices as a stable, engineered cap over in-situ contaminated sediments to isolate them from the marine environment.

Conclusion: A Clear Path Forward for Sustainable Dredging

As environmental guidelines tighten and the world maritime enterprise strikes towards larger sustainability, the common "dredge-and-dump" strategy is no longer achievable for contaminated sediments. Geotube dewatering science provides a proven, practical, and accountable alternative. By reworking hazardous, liquid slurry into manageable, stable waste, this approach without delay addresses the core economic and ecological challenges of current dredging projects. For port engineers, assignment managers, and environmental regulators in search of a compliant, cost-effective, and dependable solution, integrating Large Dewatering Bags into a complete Sludge Bag Dewatering System is a strategic decision. It’s no longer basically about disposal; it’s about imposing a smarter, cleaner Sludge Filter Bags-based method that safeguards our waterways whilst making sure the uninterrupted drift of commerce.

Contact Us

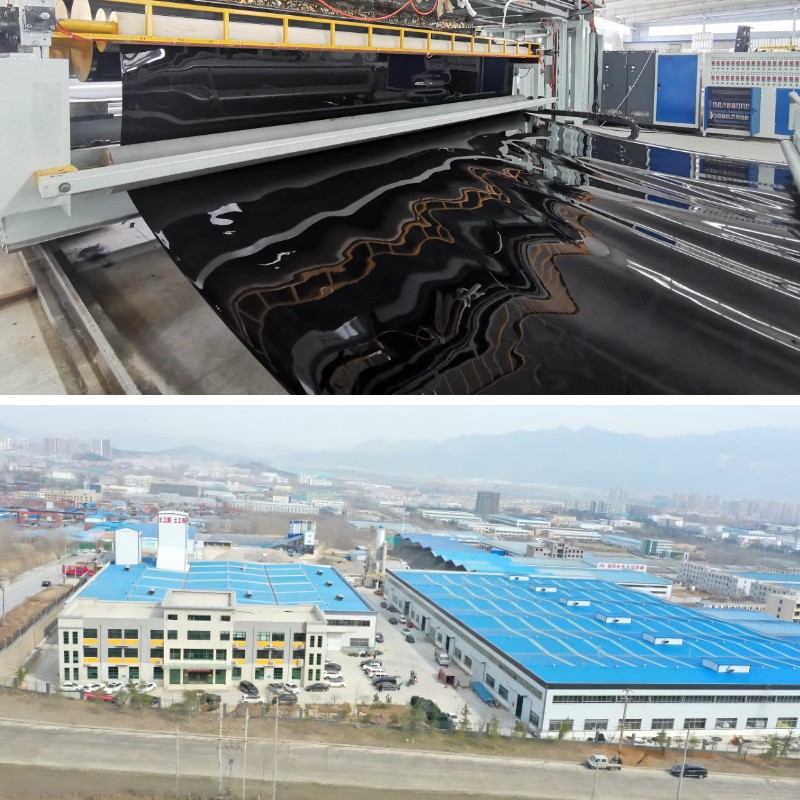

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province