HDPE Geocell Infill Materials: Choosing Gravel, Sand, or Soil for Optimal Stability

When it comes to setting up stable, long lasting civil engineering tasks the usage of hdpe geocell systems, the determination of infill substances is a necessary choice that at once influences structural performance, longevity, and cost-effectiveness. Gravel, sand, and soil are the three most frequent infill options, every with special homes that make them appropriate for particular applications—from avenue building to geocell slope protection. The proper preference relies upon on elements like venture requirements, environmental conditions, and compatibility with geocell material. In this guide, we’ll ruin down the key concerns for every material, supporting you make an knowledgeable choice to obtain greatest stability.

1. Key Properties of Gravel, Sand, and Soil: Foundations for HDPE Geocell Performance

Before diving into application-specific choices, it’s integral to recognize the indispensable traits of gravel, sand, and soil, as these houses dictate how they engage with hdpe geocell structures. The overall performance of a geocell fabric device depends closely on the infill’s capacity to switch loads, withstand erosion, and keep compaction—traits that fluctuate notably throughout the three materials.

Gravel: High Strength and Drainage for Heavy-Duty Applications

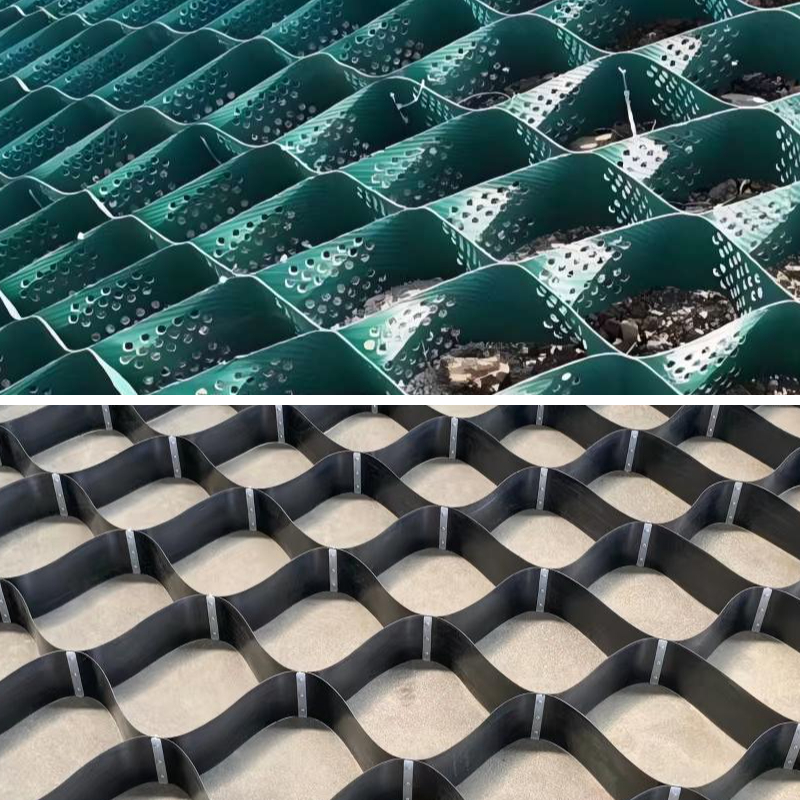

Gravel, described as coarse aggregates with particle sizes ranging from 4.75 mm to seventy five mm, is prized for its gorgeous load-bearing ability and permeability. When used as infill for hdpe geocell, gravel interlocks tightly inside the mobilephone structure, growing a inflexible composite that successfully distributes vertical and horizontal forces. This interlocking motion minimizes agreement and lateral displacement, making it best for high-traffic areas like highways, industrial yards, or protecting walls.

Another key gain of gravel is its top of the line drainage. Unlike finer materials, gravel approves water to ignore thru quickly, decreasing hydrostatic strain on thegeocell cloth and stopping waterlogging— a integral component in geocell slope safety tasks the place erosion from standing water is a foremost risk. However, gravel’s excessive density capacity it requires heavy equipment for compaction, and its fee can be greater than sand or soil in areas the place it’s now not domestically available.

Sand: Uniform Compaction for Moderate Loads

Sand consists of medium-sized particles (0.075 mm to 4.75 mm) that provide excellent compaction residences and average strength. When crammed into hdpe geocell panels, sand compacts uniformly to structure a dense, secure base that performs properly in purposes with reasonable load requirements, such as residential driveways, walkways, or light-duty get right of entry to roads. Its uniform particle measurement ensures regular load distribution throughout the geocell material, lowering stress concentrations that can lead to telephone damage.

Sand additionally affords higher workability than gravel, as it can be compacted with lighter gear and flows without difficulty into the corners of hdpe geocell cells. However, its drainage potential is decrease than gravel, and it may also require extra drainage structures in areas with heavy rainfall—especially for geocell slope safety the place water runoff can motive sand to wash out if now not suitable stabilized. Additionally, sand’s shear electricity is decrease than gravel, making it unsuitable for heavy-load applications.

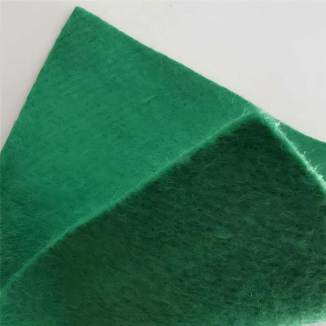

Soil: Cost-Effectiveness for Low-Stress Environments

Soil, the most with no trouble accessible and inexpensive infill option, is composed of a combine of sand, silt, clay, and natural matter. Its overall performance as hdpe geocell infill relies upon closely on its composition: well-graded, sandy loam soils provide higher steadiness than clay-heavy soils, which have a tendency to swell when moist and decrease when dry, main to uneven settlement.

Soil is nice applicable for low-stress purposes like landscaping, light-foot site visitors areas, or brief structures. When used in geocell slope safety for mild slopes, excellent compacted soil can guide vegetation growth, bettering erosion resistance and aesthetic appeal. However, soil requires cautious preparation—including drying, sieving, and compaction—to make certain compatibility with geocell material. It additionally has negative drainage, so it might also want soil amendments (like including sand or gravel) to enhance balance in moist conditions.

2. Application-Specific Selection: Prioritizing Geocell Slope Protection and Beyond

The foremost infill fabric for hdpe geocell varies dramatically primarily based on the project’s purpose. No software highlights this extra than geocell slope protection, the place erosion resistance and long-term balance are paramount. Below, we ruin down cloth options for frequent hdpe geocell applications, with a focal point on slope protection.

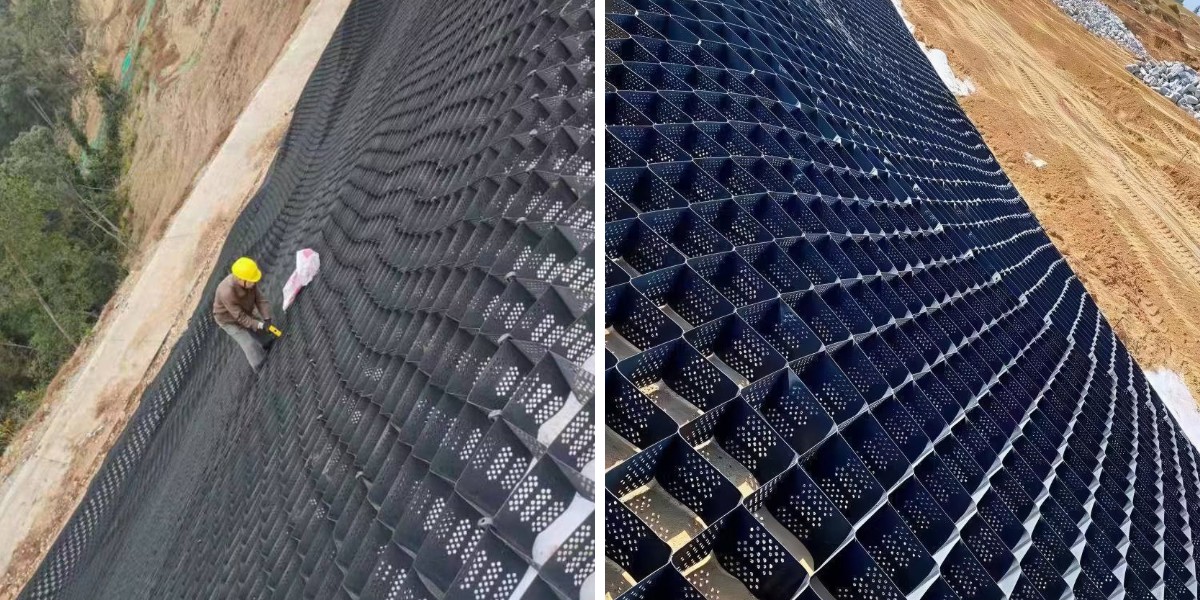

Geocell Slope Protection: Erosion Resistance as the Top Priority

Slope safety tasks demand infill substances that can withstand water runoff, forestall soil erosion, and preserve structural integrity on angled surfaces. For steep slopes (greater than 30 degrees) or high-erosion areas (like coastal areas or areas with heavy rainfall), gravel is the perfect choice. Its coarse particles lock into the hdpe geocell structure, developing a non-porous barrier that withstands water waft and minimizes particle displacement. Gravel’s drainage homes additionally decrease the chance of slope failure due to water accumulation.

For mild slopes (less than 30 degrees) or tasks targeted on ecological restoration, soil blended with gravel or sand is a higher option. The soil helps vegetation growth, which similarly stabilizes the slope, whilst the brought aggregates enhance drainage and shear strength. In these cases, making sure the soil is well matched with the geocell cloth (i.e., now not too clay-heavy) is vital to keep away from swelling and settlement. Sand is hardly ever used by myself for geocell slope safety due to its susceptibility to washout, however it can be combined with gravel to enhance compaction.

Road and Pavement Construction: Load-Bearing Capacity First

In street construction, hdpe geocell structures are used to support subgrades and base courses, decreasing rutting and extending pavement life. For high-traffic highways or industrial roads, gravel is the desired infill due to its amazing load-bearing potential and resistance to deformation. The mixture of hdpe geocell and gravel creates a inflexible base that distributes heavy masses evenly, decreasing stress on the underlying soil.

For residential roads or light-duty pavements, sand is a budget friendly alternative. It compacts tightly to shape a steady base, and when paired with geocell material, it presents adequate energy for passenger vehicles. Soil is typically now not encouraged for avenue functions until closely amended with gravel, as it lacks the shear power to stand up to repeated visitors loads.

Retaining Walls and Embankments: Stability and Drainage Balance

Retaining partitions and embankments require infill substances that can withstand lateral strain and stop wall failure. Gravel is the pinnacle desire here, as its interlocking particles and excessive drainage ability decrease hydrostatic stress on the hdpe geocell and keeping structure. Sand can be used for low-height partitions or embankments with mild loads, however it requires applicable drainage structures to keep away from water buildup. Soil is solely appropriate for small, transient holding walls, as it tends to keep water and exert immoderate lateral stress over time.

3. Compatibility with Geocell Material: Ensuring Long-Term Performance

The success of any hdpe geocell venture relies upon on the compatibility between the infill fabric and the geocell fabric itself. HDPE (high-density polyethylene) is a durable, chemical-resistant material, however it can be broken with the aid of sharp, angular particles or immoderate compaction forces. Understanding how gravel, sand, and soil have interaction with hdpe geocell is key to averting untimely failure.

Gravel and Geocell Material Compatibility

While gravel affords incredible strength, its angular particles can pose a hazard to geocell cloth if no longer appropriate graded. Sharp-edged gravel can puncture or abrade the HDPE panels at some point of set up or compaction. To mitigate this, use well-rounded gravel with a most particle dimension no large than half of the telephone top of the hdpe geocell. Additionally, keep away from over-compacting gravel, as immoderate strain can stretch or tear the geocell panels.

Sand and Soil Compatibility Considerations

Sand is commonly extra like minded with hdpe geocell than gravel, as its rounded particles are much less possibly to harm the HDPE panels. However, excellent sand can seep thru small gaps in the geocell shape if now not exact compacted, main to settlement. For soil, the principal compatibility difficulty is moisture content: clay-heavy soils that swell when moist can exert immoderate strain on the geocell material, inflicting it to deform. Always check soil composition and moisture stages earlier than use, and amend with aggregates if necessary.

4. Cost-Effectiveness and Long-Term Maintenance

Beyond performance, fee and protection are quintessential elements in infill fabric selection. While gravel affords top-quality performance, it can also now not be the most low-priced alternative in areas the place it’s scarce. Sand and soil, being extra effectively available, are frequently more cost-effective upfront, however they might also require extra usual protection or amendments to hold stability—especially ingeocell slope safety projects.

Upfront Costs: Soil < Sand < Gravel

Soil is the most inexpensive infill option, as it can frequently be sourced on-site, doing away with transportation costs. Sand is barely greater high-priced than soil however nonetheless extra cheap than gravel. Gravel’s excessive fee is due to its mining and transportation requirements, specifically in areas a long way from quarries. However, it’s essential to reflect onconsideration on the project’s lifespan: gravel’s sturdiness may additionally offset its greater upfront price via lowering the want for repairs.

Long-Term Maintenance: Gravel < Sand < Soil

Gravel requires the least maintenance, as its interlocking shape and drainage homes forestall erosion and settlement. Sand can also want periodic recompaction to keep stability, specially in high-traffic or moist areas. Soil requires the most maintenance: it might also want regrading, amending with aggregates, or reseeding vegetation in geocell slope safety initiatives to stop erosion. Additionally, clay-heavy soils may additionally require drainage structures to keep away from swelling and shrinkage.

Final Recommendations: Choosing the Right Infill for Your HDPE Geocell Project

To summarize, the desire between gravel, sand, and soil for hdpe geocell infill relies upon on your project’s precise needs:

Choose gravel for heavy-load purposes (highways, industrial yards), steep slope protection, or areas with excessive rainfall. It gives the quality energy and drainage however comes with a greater upfront cost.

Choose sand for light-duty roads, residential driveways, or low-height preserving walls. It’s affordable and effortless to compact however requires drainage structures in moist areas.

Choose soil for low-stress functions (landscaping, mild slopes) or tasks targeted on ecological restoration. It’s the most inexpensive choice however requires cautious coaching and ongoing maintenance.

No be counted which fabric you choose, making sure compatibility with geocell fabric and applicable set up (including compaction and drainage) is necessary for highest quality stability. For specialised initiatives like geocell slope protection, consulting with a civil engineering expert can assist you choose the first-class infill fabric for your particular environmental and structural necessities

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province