Geomembrane Repair & Maintenance: Extending Lifespan & Performance

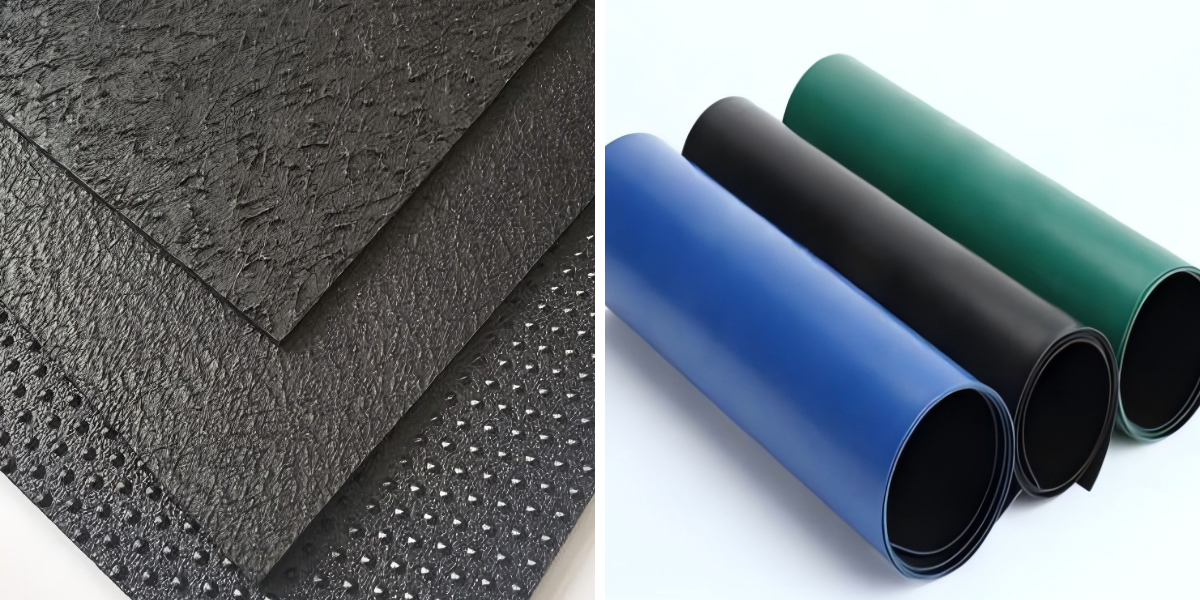

Geomembranes are artificial membranes made from excessive - density polyethylene (HDPE), linear low - density polyethylene (LLDPE), polyvinyl chloride (PVC), and different polymers. Among them, the HDPE membrane, also regarded as the HDPE liner sheet, is one of the most frequent types. HDPE membranes are famous due to their wonderful chemical resistance, excessive tensile strength, and fantastic durability.

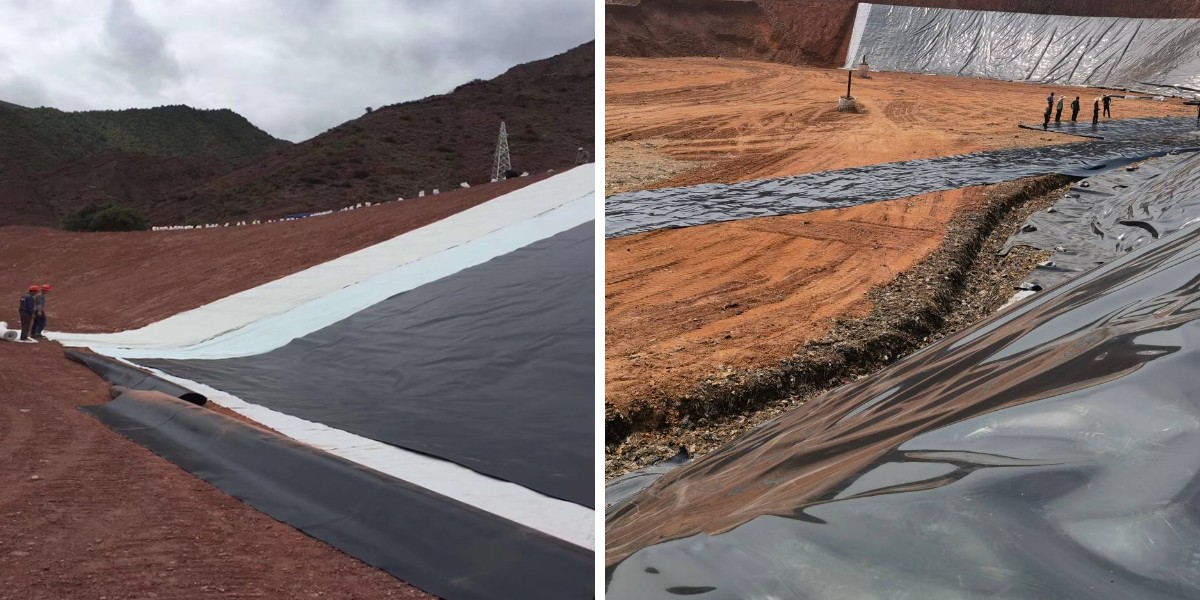

These geomembranes have a extensive vary of functions throughout a number industries. In the environmental sector, they are drastically used in landfill liners to forestall the leakage of detrimental elements from waste into the soil and groundwater. For example, in massive - scale landfill projects, HDPE geomembranes act as a necessary barrier, successfully containing leachate and defending the surrounding environment. In the water aid administration field, they are used in the building of reservoirs, canals, and ponds. A properly - mounted HDPE liner sheet in an synthetic lake can make sure water tightness, lowering water seepage and keeping the water level. In the agricultural industry, geomembranes are used in aquaculture ponds to create a smooth and managed surroundings for fish and shrimp farming.

In essence, geomembranes play a quintessential function in present day engineering projects. They are the unsung heroes that guard our environment, maintain water resources, and help industrial and agricultural activities, making them an fundamental section of infrastructure development.

The Significance of Repair and Maintenance

Even the best possible - exceptional geomembranes, such as HDPE membranes, are now not immune to put on and tear over time. Regular restore and renovation are critical for various reasons. Firstly, ideal renovation can drastically prolong the lifespan of geomembranes. A nicely - maintained HDPE liner sheet in a landfill can serve for decades, constantly satisfying its feature of waste containment. Without maintenance, elements like UV radiation, mechanical stress, and chemical publicity can progressively degrade the membrane, main to untimely failure.

Secondly, protection is essential for making sure the highest quality overall performance of geomembranes. A broken geomembrane in a water - preserving shape may also lead to water leakage, decreasing the effectivity of water storage and doubtlessly inflicting harm to the surrounding area. By without delay repairing any punctures, tears, or different defects, the integrity of the membrane can be restored, and its overall performance can be maintained at a excessive level.

In summary, the restore and renovation of geomembranes are now not simply after - thinking things to do however necessary components of any mission that makes use of these materials. The following sections will delve deeper into the techniques and fantastic practices of geomembrane restore and maintenance.

Common Types of Geomembrane Damage

Physical Damage

Physical harm to geomembranes is a widespread issue. Punctures can take place when sharp objects, such as rocks, development debris, or tree roots, come into contact with the membrane. For example, all through the development of a landfill, if giant rocks are now not accurate cleared from the web site earlier than laying the HDPE liner sheet, they can pierce the membrane over time due to agreement or exterior pressure.

Mechanical stress in the course of building is every other main motive of bodily damage. Heavy equipment working on or close to the geomembrane can exert immoderate pressure, main to tears or cracks. In a reservoir building project, if bulldozers or excavators by accident force over the HDPE membrane except suitable safety measures, the membrane's integrity will be compromised. Additionally, floor contract can reason the geomembrane to stretch and ultimately rupture. When the underlying soil experiences differential settlement, the geomembrane is subjected to uneven stress, which is specially frequent in areas with tender or unstable soil conditions.

Chemical Degradation

Chemical degradation can considerably decrease the lifespan and overall performance of geomembranes. Geomembranes, mainly HDPE membranes, may additionally come into contact with a range of chemical materials in one of a kind applications. In industrial waste disposal sites, the waste might also incorporate sturdy acids, alkalis, or solvents. For instance, if a landfill receives industrial waste with excessive - awareness sulfuric acid, the acid can step by step corrode the HDPE membrane. Over time, the chemical response between the acid and the HDPE cloth can lead to a loss of tensile electricity and flexibility of the membrane.

Certain chemical substances can additionally motive swelling or embrittlement of the geomembrane. Solvents like benzene or toluene, if current in the surroundings the place the geomembrane is installed, can penetrate the polymer shape of the HDPE membrane. This penetration can disrupt the molecular association of the polymer, inflicting the membrane to swell initially. In the lengthy run, repeated publicity to such solvents can make the membrane brittle, growing its susceptibility to cracking beneath ordinary stress conditions.

Environmental Wear and Tear

Environmental elements play a essential function in the degradation of geomembranes. UV radiation from the solar is a essential concern, in particular for geomembranes uncovered to sunlight. HDPE membranes, even though enormously resistant to UV degradation in contrast to some different polymers, are now not immune. Prolonged publicity to UV rays can wreck down the polymer chains in the HDPE material. For example, in an uncovered water storage pond lined with an HDPE membrane, over countless years, the UV - uncovered areas of the membrane may additionally exhibit signs and symptoms of floor cracking and discoloration.

Temperature variants can additionally influence geomembranes. Extreme warmth can soften the HDPE membrane, making it greater prone to bodily damage. In warm barren region regions, the place temperatures can leap all through the day, the HDPE liner sheets in landfills might also come to be softer, and any underlying stress or sharp objects can greater effortlessly purpose punctures. On the different hand, extraordinarily bloodless temperatures can make the membrane brittle. In bloodless - local weather areas, the membrane can also crack when subjected to surprising stress modifications at some stage in freeze - thaw cycles.

Biological elements can additionally make a contribution to the degradation of geomembranes. Microorganisms, such as micro organism and fungi, can develop on the floor of the membrane in some environments. These microorganisms can secrete enzymes that can wreck down the polymer factors of the HDPE membrane. In a wetland venture the place the geomembrane is in contact with water and prosperous natural matter, microbial boom can speed up the degradation manner of the membrane over time.

Detection Methods for Geomembrane Damage

Visual Inspection

Visual inspection is the most primary and simple approach for detecting geomembrane damage. It includes at once staring at the floor of the geomembrane, such as the HDPE liner sheet, with the bare eye or with the useful resource of easy equipment like magnifying glasses. During the inspection, operators have to appear for apparent symptoms of damage. These encompass seen punctures, which can also show up as small holes in the HDPE membrane. Tears can be recognized as linear breaks in the membrane, and cracks are typically thin, hair - like fissures on the surface.

When conducting a visible inspection, it is necessary to work systematically. Start from one nook of the geomembrane - lined location and cross in an orderly manner, making sure that each and every section of the floor is examined. Pay one of a kind interest to areas round anchor points, joints, and corners, as these are extra susceptible to stress attention and damage. For example, in a landfill, the joints between one of a kind sections of the HDPE liner sheet want to be cautiously inspected, as flawed welding or exterior forces can purpose these areas to separate or enhance cracks. Visual inspection is now not solely about searching for giant - scale injury however additionally about noticing any refined adjustments in the membrane's appearance, such as discoloration or floor irregularities, which should be early symptoms of degradation.

Electronic Leak Detection

Electronic leak detection is a extra superior and touchy approach for figuring out harm in geomembranes, specifically for detecting small - scale leaks that can also now not be seen to the bare eye. This approach is based totally on the precept of electrical conductivity. A low - voltage electrical present day is utilized to the geomembrane, and the HDPE membrane, being an insulator, ought to no longer habits electricity below everyday circumstances. However, if there is a defect or a leak in the membrane, the electrical cutting-edge will locate a course thru the conductive medium (such as the underlying soil or the liquid in contact with the membrane), growing a measurable electrical signal.

The manner of the use of digital leak detection tools entails quite a few steps. First, the tools is set up correctly, making sure that the electrodes are appropriate positioned on or close to the geomembrane. The operator then slowly strikes the detection system throughout the floor of the HDPE membrane. When the gadget passes over a leak point, it will emit a signal, such as a beep or a alternate in the studying on a show screen. This permits for the unique vicinity of the leak. One of the essential benefits of digital leak detection is its excessive sensitivity. It can realize very small leaks, down to a few millimeters in diameter, which may be ignored throughout a visible inspection. This makes it an worthwhile device for making sure the integrity of geomembranes in essential applications, such as in hazardous waste containment facilities.

Pressure Testing

Pressure trying out is any other superb way to notice injury in geomembranes, specially for these used in purposes the place the membrane is predicted to hold a positive strain differential, such as in water - maintaining structures. The fundamental precept of strain trying out is to introduce a regarded quantity of strain into the area between the geomembrane and the underlying shape or into a closed device the place the geomembrane is an necessary part. For an HDPE - lined reservoir, air or water can be pumped into the area between the HDPE membrane and the reservoir wall.

The implementation steps are as follows. First, seal the vicinity to be examined to create a closed system. Then, use a strain - producing device, such as a pump, to make bigger the strain interior the machine to a pre - decided level. Monitor the stress over a length of time. If the geomembrane is intact, the stress need to stay surprisingly stable. However, if there is a leak or harm in the HDPE membrane, the stress will progressively decrease. By measuring the charge of stress drop, it is feasible to decide the severity of the damage. For example, a fast stress drop suggests a substantial leak, whilst a gradual and constant decline may also advocate a smaller, extra hard - to - become aware of defect. Pressure trying out offers a quantitative evaluation of the geomembrane's integrity and can be used to consider the effectiveness of repairs as well.

Repair Techniques for Geomembranes

Patch Repair

Patch restore is a often used technique for fixing small - to - medium - sized damages in geomembranes, in particular for HDPE membranes. This method is appropriate when there are punctures, small tears, or areas of localized damage. For example, if a small gap is detected in an HDPE liner sheet in a pond due to a sharp object, patch restore can be an superb solution.

The operation steps are as follows. First, easy the broken location thoroughly. Remove any dirt, debris, or moisture from the floor of the HDPE membrane round the harm site. This ensures appropriate adhesion between the patch and the membrane. Then, reduce a patch from a fabric that is the equal as or like minded with the HDPE membrane. The patch have to be massive adequate to cowl the broken region with a adequate overlap, normally at least 10 - 15 centimeters on all sides. Next, practice a appropriate adhesive or use a welding approach (depending on the kind of patch material) to connect the patch to the membrane. Press the patch firmly onto the membrane to make sure a tight bond, putting off any air bubbles trapped between the patch and the membrane. Finally, behavior a fantastic check, such as a easy visible inspection or a small - scale strain take a look at in the repaired area, to make certain that the restore is effective.

Welding Repair

Welding restore is a exceedingly fantastic approach for becoming a member of and repairing geomembranes, specifically for HDPE liner sheets. The precept of welding restore is to use warmth to soften the surfaces of the HDPE membrane and the restore fabric (if applicable) or the two components of the broken membrane, permitting them to fuse collectively and structure a robust bond.

There are specific welding methods available. One frequent approach is thermal wedge welding. In thermal wedge welding, a heated wedge is positioned between the two layers of the HDPE membrane (or the membrane and the patch). As the wedge strikes alongside the joint, it melts the surfaces of the HDPE material. Simultaneously, strain is utilized to press the melted surfaces together, growing a welded seam. This technique is appropriate for giant - scale repairs and becoming a member of of HDPE membranes, such as in landfill liner installations the place lengthy seams want to be repaired.

Another technique is extrusion welding. In extrusion welding, a welding gun extrudes a bead of molten HDPE cloth onto the joint or broken area. The gun strikes alongside the restore site, depositing the molten cloth whilst concurrently making use of warmness and stress to bond the extruded cloth to the present HDPE membrane. This approach is frequently used for repairing irregular - fashioned damages or for making repairs in areas the place it is hard to use different welding methods. For example, when repairing a complicated - fashioned tear in an HDPE membrane in a water - therapy plant, extrusion welding can grant a bendy and fantastic solution.

When performing welding repair, it is essential to make sure that the welding parameters, such as temperature, pressure, and welding speed, are set successfully in accordance to the kind and thickness of the HDPE membrane. Incorrect parameters can lead to vulnerable welds, which may additionally reason the repaired place to fail once more in the future.

Chemical Adhesive Repair

Chemical adhesive restore is a appropriate alternative for sure kinds of harm in HDPE membranes, specially when welding is no longer viable or when dealing with small - scale, non - structural damages. This technique is frequently used in conditions the place the broken location is in a challenging - to - attain region or when the membrane cloth is now not without problems weldable. For example, in a small - scale agricultural pond lined with an HDPE membrane, if there are some minor punctures in a nook region that is tough to get entry to for welding, chemical adhesive restore can be a realistic choice.

When the use of chemical adhesive repair, it is fundamental to select the proper adhesive. The adhesive have to be well suited with the HDPE membrane material. There are specialised adhesives reachable in the market that are designed mainly for bonding HDPE materials. Before making use of the adhesive, easy the broken vicinity of the HDPE membrane wholly to do away with any contaminants. Then, observe the adhesive evenly to each the broken region of the membrane and the patch (if the usage of a patch). Press the patch onto the broken location firmly, making sure precise contact between the two surfaces. Follow the manufacturer's guidelines related to the curing time of the adhesive. Curing instances can range relying on the kind of adhesive and the environmental conditions, however generally, it is indispensable to enable enough time for the adhesive to utterly harden and shape a robust bond. Also, be conscious of the security precautions when the use of chemical adhesives, as some adhesives can also launch damaging fumes. Work in a nicely - ventilated vicinity and put on fantastic non-public defensive equipment, such as gloves and a mask.

Maintenance Strategies for Geomembranes

Regular Inspection Schedules

Regular inspection is the cornerstone of tremendous geomembrane maintenance. For newly set up geomembranes, such as HDPE liner sheets, it is really useful to behavior a thorough inspection inside the first few weeks after installation. This preliminary inspection helps to pick out any attainable harm that may additionally have came about throughout the set up process, such as punctures from building equipment or wrong welding of seams.

In everyday working conditions, a everyday guiding principle for HDPE membranes is to operate inspections at least as soon as each and every six months. However, the inspection frequency may additionally want to be adjusted based totally on the particular utility and environmental conditions. For example, in landfill purposes the place the HDPE membrane is uncovered to a massive quantity of waste and conceivable chemical contaminants, inspections ought to be carried out quarterly. In areas with excessive - visitors or ordinary building things to do close to the geomembrane - lined site, greater time-honored inspections are additionally essential to realize any new damages promptly. In severe environmental conditions, such as areas with excessive UV radiation, robust winds, or heavy rainfall, the inspection frequency can also want to be extended to month-to-month or even bi - weekly to make sure the integrity of the HDPE membrane.

Cleaning and Debris Removal

Keeping the floor of the geomembrane smooth and free of particles is integral for preserving its performance. Debris, such as leaves, branches, and rocks, can accumulate on the floor of the HDPE membrane. Over time, these substances can lure moisture, which may also speed up the degradation of the membrane. For example, in a water - storage pond lined with an HDPE membrane, leaves and algae boom on the membrane floor can block daylight from attaining the water, main to modifications in water quality. Additionally, sharp particles like rocks can purpose punctures or abrasions on the membrane if no longer eliminated in a well timed manner.

The cleansing technique for geomembranes relies upon on the kind of particles and the nature of the application. For commonplace filth and mild debris, a easy water rinse the usage of a low - stress hose can be sufficient. Gently spray the water onto the floor of the HDPE membrane, beginning from one give up and transferring throughout the complete surface. For extra cussed dust or natural matter, a moderate detergent can be brought to the water. However, it is critical to make certain that the detergent is like minded with the HDPE membrane material. Avoid the usage of harsh chemical substances or abrasive cleaners, as they can harm the membrane surface. After making use of the detergent - water solution, rinse the membrane totally with smooth water to dispose of any residue.

When getting rid of large debris, such as branches or giant rocks, use equipment like rakes or shovels with care to keep away from scratching or puncturing the HDPE membrane. In some cases, if the debris is firmly connected to the membrane, it may additionally be fundamental to use a smooth - bristled brush to gently loosen it earlier than removal.

Protection from External Factors

To guard geomembranes, particularly HDPE membranes, from exterior factors, various measures can be taken. One of the most advantageous methods is to deploy a shielding layer on pinnacle of the HDPE liner sheet. In landfill applications, a layer of soil or geotextile can be positioned over the HDPE membrane. The soil layer no longer solely gives bodily safety towards mechanical injury however additionally helps to decrease the affect of UV radiation. The geotextile, on the different hand, can stop the intrusion of small particles and additionally act as a cushion, lowering the danger of punctures from sharp objects in the soil.

Setting up clear warning symptoms round the geomembrane - lined location is additionally important. These symptoms can alert human beings to the presence of the geomembrane and limit things to do that can also injury it, such as unauthorized digging or using heavy automobiles over the area. In development web sites the place the HDPE membrane is quickly uncovered for the duration of the building process, fencing can be erected round the vicinity to stop unintentional harm from building tools or workers.

In addition, when designing a challenge the usage of geomembranes, think about the area and orientation of the installation. Avoid setting the HDPE membrane in areas the place it is probably to be without delay uncovered to sturdy daylight for lengthy periods. If possible, installation the membrane in shaded areas or use shading buildings to minimize the influence of UV radiation. For areas inclined to excessive climate conditions, such as excessive - wind or heavy - snow regions, fortify the set up and safety measures to make sure the lengthy - time period balance and integrity of the HDPE membrane.

The Cost - Benefit of Geomembrane Repair and Maintenance

Cost of Repairs and Maintenance

The price of repairing and keeping geomembranes, such as HDPE membranes, can differ drastically relying on quite a few factors. For materials, the price of patches, adhesives, or welding consumables for HDPE liner sheets is a phase of the expense. A small patch made of HDPE fabric for a minor puncture in an HDPE membrane may additionally fee round 5 - 20, relying on the dimension and fantastic of the patch. Chemical adhesives appropriate for HDPE membranes can vary from 10 - 50 per liter, and the quantity used relies upon on the dimension of the restore area.

Labor expenses additionally play a fundamental role. Skilled people are required for welding repairs. In areas with an common labor cost, the hourly wage for a geomembrane restore technician can be round 20 - 50. For a small - scale patch restore that may also take a technician about 1 - two hours, the labor price would be about 20 - 100. For greater complicated welding repairs, such as repairing a lengthy seam in a giant - scale landfill HDPE liner sheet, if it takes a group of two technicians 5 - 10 hours, the labor value may want to attain 200 - 1000, no longer along with the value of tools operation and transportation.

Cost of Premature Replacement

Premature substitute of geomembranes due to lack of acceptable restore and protection can be extraordinarily costly. The price of paying for new HDPE membranes can be substantial. For a fashionable - best HDPE membrane with a thickness of 1 - two millimeters, the cloth price per rectangular meter can vary from 3 - 10. In a giant - scale landfill task masking various hectares, the vicinity of the HDPE liner sheet can be tens of heaps of rectangular meters. Just the cloth price for substitute may want to quantity to heaps of lots of dollars.

In addition to cloth costs, the value of re - laying the geomembrane additionally wants to be considered. This consists of the fee of equipment, such as heavy - obligation equipment for website preparation, which can fee hundreds of bucks per day to rent. Labor expenses for a giant - scale alternative undertaking can be even higher. A group of workers, together with these for web site preparation, membrane installation, and high-quality inspection, may also want to work for weeks. The complete labor value for a challenge of this scale should without problems exceed $100,000. There are additionally practicable oblique costs, such as the loss of operation in the course of the alternative period, which can motive economic losses for the assignment owner.

Long - Term Savings and Benefits

Effective restore and protection of geomembranes provide full-size lengthy - time period financial savings and benefits. By often inspecting and right now repairing HDPE membranes, the danger of leakage can be radically reduced. In a water - cure plant, stopping a important leakage thru suited protection can keep away from luxurious smooth - up operations and plausible harm to the surrounding environment, which should price thousands of hundreds of greenbacks in remediation efforts.

Maintenance additionally extends the lifespan of geomembranes. A nicely - maintained HDPE liner sheet in a landfill can ultimate 20 - 30 years or even longer, in contrast to a in advance broken one that may also want substitute after 5 - 10 years. This prolonged lifespan capability that the want for high priced replacements is postponed, ensuing in significant financial savings over time. Moreover, the steady overall performance of a properly - maintained geomembrane ensures the ordinary operation of the project. In an aquaculture pond, a dependable HDPE membrane helps keep water pleasant and a appropriate surroundings for fish growth, contributing to greater yields and monetary returns for farmers.

Conclusion

Recap of Key Points

In this article, we have explored the imperative elements of geomembrane restore and maintenance. Geomembranes, specially HDPE membranes or HDPE liner sheets, are critical in quite a number engineering applications, from environmental safety to water aid management. However, they are inclined to one-of-a-kind kinds of damage. Physical damage, such as punctures and tears precipitated by way of sharp objects and mechanical stress, can compromise the integrity of the geomembrane. Chemical degradation, resulting from publicity to acids, alkalis, and solvents, and environmental put on and tear due to UV radiation, temperature variations, and organic factors, additionally pose great threats to their lifespan and performance.

To make sure the applicable functioning of geomembranes, positive detection strategies are essential. Visual inspection permits for the identification of apparent damages, whilst digital leak detection can pinpoint small - scale leaks that are invisible to the bare eye. Pressure checking out is beneficial for detecting injury in functions the place strain - keeping is crucial.

When it comes to repair, patch restore is suitable for small - to - medium - sized damages, welding restore presents a robust and long lasting solution, specifically for giant - scale repairs and joining, and chemical adhesive restore can be used in conditions the place welding is no longer feasible. Regular preservation strategies, along with putting up ordinary inspection schedules, cleansing and particles removal, and defending the geomembrane from exterior factors, are additionally quintessential to its lengthy - time period performance. Moreover, the value - gain evaluation indicates that appropriate restore and upkeep can lead to enormous lengthy - time period financial savings in contrast to untimely replacement.

Encouragement for Proper Maintenance

It is of utmost significance for venture owners, engineers, and all these concerned in initiatives the usage of geomembranes to prioritize restore and maintenance. By doing so, no longer solely can the lifespan of the geomembrane be extended, however additionally the overall performance and protection of the whole assignment can be guaranteed. Regular inspections, well timed repairs, and perfect protection measures are now not solely value - high-quality in the lengthy run however additionally make contributions to environmental protection and the sustainable operation of more than a few facilities. Don't forget the significance of geomembrane maintenance; take motion these days to make certain the lengthy - time period success of your projects.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province