Geocell vs. Traditional Slope Protection: Which Offers Better Durability?

In slope safety engineering, sturdiness immediately determines the security and carrier lifestyles of a project. With the improvement of geosynthetic materials, geocell cloth has progressively turn out to be a famous choice, competing with usual slope safety strategies such as stone masonry and concrete spraying. This article will examine geocell-based options (including geoweb slope protection) with ordinary technologies, focusing on their sturdiness performance, to assist you figure out which is extra appropriate for your project.

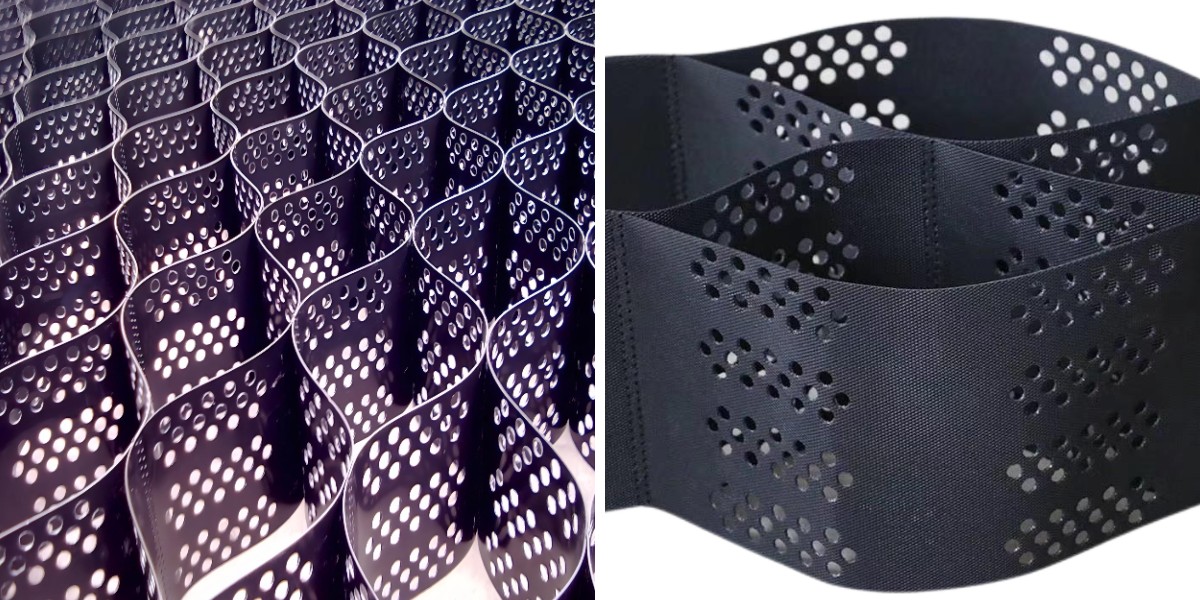

What Is Geocell Material and How Does It Work for Slope Protection?

Geocell fabric is a 3-dimensional grid shape made of high-density polyethylene (HDPE) or polypropylene. When unfolded, it types a honeycomb-like device that can be stuffed with soil, gravel, or vegetation. This graph creates a secure "confining effect"—the cells prevent the motion of crammed materials, improving the typical shear power of the slope.

Geocell for slope safety works through distributing the weight of the slope evenly and resisting exterior forces such as rainfall erosion and soil lateral displacement. Unlike inflexible structures, it continues a sure diploma of flexibility, permitting moderate deformation except cracking when the slope settles. This flexibility is a key issue in its durability, mainly in areas susceptible to minor floor movement.

Geoweb slope protection, a frequent utility structure of geocell material, is broadly used in street embankments, riverbanks, and toll road slopes. Its modular plan simplifies set up and ensures uniform stress distribution, laying a stable basis for long-term durability.

Traditional Slope Protection Methods: Durability Advantages and Limitations

Traditional slope safety strategies have been used for decades, with consultant applied sciences which include dry stone masonry, shotcrete, and gabion baskets. These strategies matter on inflexible or semi-rigid buildings to withstand slope erosion and instability.

Dry stone masonry makes use of herbal stones stacked to structure a defensive layer. It has true permeability and can adapt to moderate slope changes, however its sturdiness is constrained by means of the bonding pressure between stones. Over time, rainwater scouring and plant root boom can also loosen the stones, requiring everyday maintenance.

Shotcrete (sprayed concrete) varieties a dense defensive layer on the slope surface, which is exceptionally resistant to erosion. However, it is inclined to cracking due to temperature modifications or slope settlement. Once cracks appear, water seeps into the slope, accelerating soil softening and decreasing the safety effect.

Gabion baskets, made of metallic mesh stuffed with stones, have higher flexibility than shotcrete. The metallic mesh, however, is inclined to corrosion in humid or coastal environments, which weakens the structural integrity over time.

Durability Comparison: Key Factors That Determine Long-Term Performance

1. Resistance to Water Erosion

Water erosion is the primary risk to slope durability. Geocell for slope safety performs nicely in this aspect: the honeycomb shape retains the crammed soil, and when mixed with vegetation, it varieties a "biological safety system" that slows down water go with the flow and reduces scouring. Even if floor soil is barely eroded, the geocell grid prevents large-scale soil loss.

Traditional strategies like shotcrete can withstand non permanent erosion however fail to take care of long-term water infiltration. Cracks in shotcrete emerge as channels for water, main to interior slope damage. Stone masonry, on the other hand, might also have gaps that enable water to seep through, steadily washing away the underlying soil.

2. Adaptability to Slope Deformation

Slope agreement or moderate motion is frequent in engineering. Geocell material, with its bendy structure, can deform synchronously with the slope barring dropping its defensive function. This "follow-up deformation" capacity avoids structural injury precipitated with the aid of inflexible war of words with exterior forces.

Traditional inflexible constructions such as concrete protecting partitions have negative adaptability to deformation. When the slope moves, the concrete is without problems pulled apart, ensuing in cracks or even collapse. Although gabion baskets have some flexibility, their metallic mesh might also damage after repeated deformation, decreasing durability.

3. Resistance to Environmental Corrosion

In harsh environments (such as coastal areas with excessive salt content material or industrial zones with chemical pollution), corrosion resistance is crucial. Geocell fabric is made of outstanding HDPE, which is resistant to chemical corrosion and does no longer rust, making sure long-term balance in corrosive environments.

Traditional metal-based safety techniques (such as gabion baskets with metal mesh) are prone to corrosion. In coastal areas, salt spray can speed up steel oxidation, and the mesh can also damage after 5-10 years, requiring replacement. Concrete-based strategies may also additionally go through from alkali-aggregate response beneath chemical erosion, lowering their strength.

4. Maintenance and Long-Term Cost

Durability is now not solely about carrier existence however additionally about upkeep costs. Geocell for slope safety requires little protection after installation. If harm occurs, solely the affected cells want to be repaired, which is easy and low-cost.

Traditional strategies regularly require established maintenance. For example, shotcrete wants to be re-sprayed each and every few years to restore cracks; stone masonry may also want to substitute unfastened stones regularly. These upkeep works now not solely expand expenses however additionally might also have an effect on the regular use of the slope in the course of construction.

Real-World Applications: Geocell vs. Traditional Slope Protection

In a motorway slope safety mission in a mountainous region with heavy rainfall, geoweb slope safety used to be used on one side, and shotcrete on the other. After three years, the geoweb-protected slope remained intact, with vegetation developing in the cells to decorate stability. In contrast, the shotcrete slope had more than one cracks, and partial peeling happened in areas with severe water scouring.

In a coastal street slope project, geocell fabric confirmed apparent blessings in corrosion resistance. After 5 years of publicity to salt spray, the geocell shape was once nevertheless stable. The adjoining gabion basket slope, however, had damaged steel meshes in some areas, and stones fell off, requiring emergency repairs.

Conclusion: Why Geocell for Slope Protection Is a Better Choice for Durability

When evaluating geocell fabric with typical slope safety methods, geocell stands out in phrases of water erosion resistance, deformation adaptability, corrosion resistance, and preservation cost. Its bendy but secure shape addresses the key ache factors of normal methods—such as handy cracking, negative corrosion resistance, and excessive upkeep needs.

For tasks pursuing long-term sturdiness (especially in areas with regular rainfall, slope motion risks, or harsh environments), geoweb slope safety and geocell for slope safety are extra dependable choices. They now not solely prolong the carrier existence of slope safety however additionally limit long-term renovation costs, bringing increased financial and protection advantages to the project.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province