Concrete Impregnated Fabric vs. Fiberglass Reinforced Plastic: Which Is Better?

Introduction: Two Innovators in Modern Construction

In the realm of durable, flexible setting up materials, Concrete Impregnated Fabric and Fiberglass Reinforced Plastic (FRP) have emerged as go-to selections for severa projects. From emergency repairs to eternal structures, each and every affords exclusive advantages—but choosing the desirable one depends upon on your project’s needs. This article compares their strengths, weaknesses, and ideal applications, with a focal factor on smart universal overall performance metrics.

What Are Concrete Impregnated Fabric and FRP?

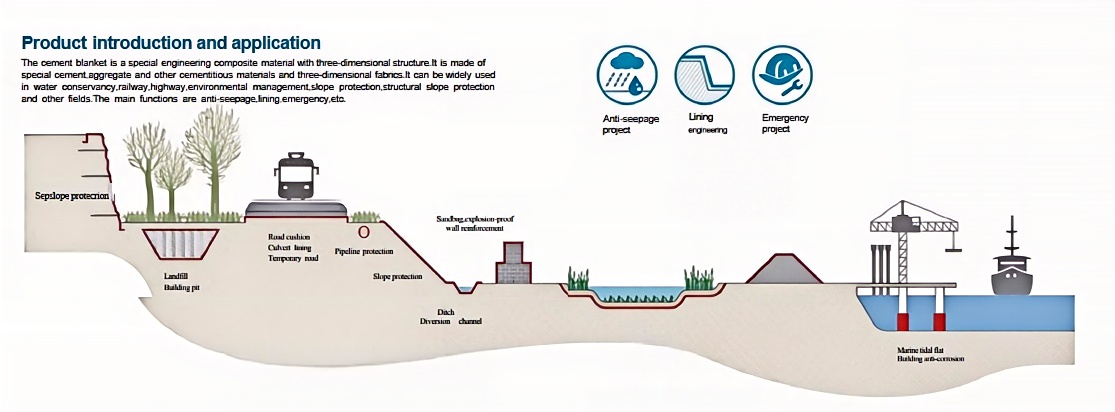

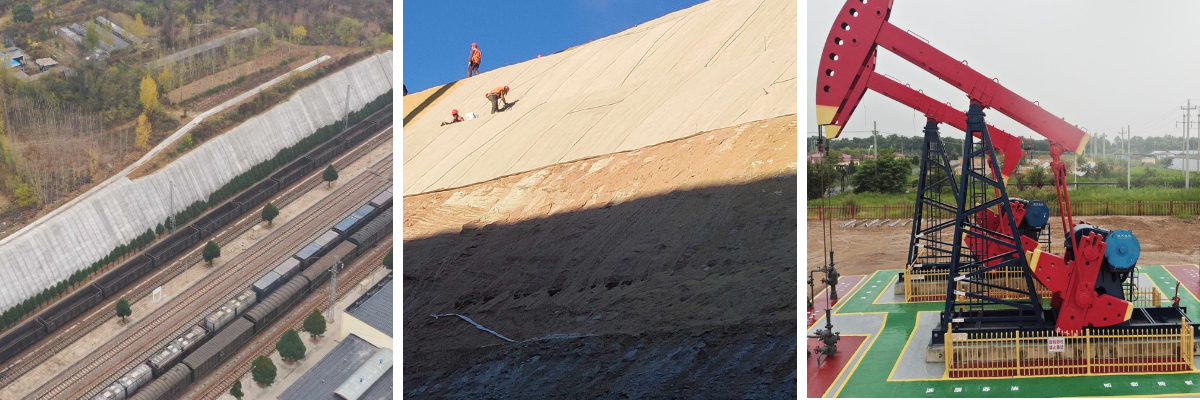

Concrete Impregnated Fabric: Also acknowledged as Cement Impregnated Fabric, this material combines a woven material matrix (typically polyester or glass fiber) with a dry cementitious compound. When hydrated, it hardens into a rigid, waterproof structure at the same time as defending flexibility in the route of installation. Variants like Instant Concrete Mat and Flexible Concrete Blanket remedy all at once (24–48 hours), making them first-class for time-sensitive projects.

Fiberglass Reinforced Plastic (FRP): FRP consists of glass fibers embedded in a polymer resin (e.g., polyester or epoxy). It is lightweight, high-strength, and molded into rigid shapes, providing splendid corrosion resistance and structural rigidity.

Key Performance Comparison

1. Strength and Structural Integrity

Concrete Impregnated Fabric: Cured Cement Impregnated Fabric(https://www.cggeosynthetics.com/cement-blanket-0/) offers you compressive electrical energy of 30–50 MPa, associated to typical concrete. Its flexibility (before full curing) approves it to conform to irregular surfaces, lowering cracking below dynamic loads. For example, a Flexible Concrete Blanket used in pipe fix can stand up to ground shifts barring breaking.

FRP: FRP excels in tensile electrical energy (100–300 MPa) due to its glass fiber reinforcement, making it ideal for load-bearing structures like beams or panels. However, it is rigid and inclined to shattering under shocking have an impact on or bending stress.

Winner: FRP for tensile strength; Concrete Impregnated Fabric for flexibility and compressive resilience.

2. Durability and Environmental Resistance

Concrete Impregnated Fabric:

Water Resistance: Once cured, Instant Concrete Mat kinds a waterproof barrier, resisting water penetration even in submerged features (e.g., canal liners).

UV and Chemical Resistance: The cementitious layer protects the cloth from UV degradation, at the same time as the fabric resists mild chemical resources (e.g., agricultural runoff). It performs good in temperatures ranging from -20°C to 60°C.

FRP:

Corrosion Resistance: FRP is immune to rust and chemical attack, making it fabulous for industrial tanks or marine structures.

UV Vulnerability: Uncoated FRP degrades under prolonged sunlight, requiring UV-stabilized resins or protecting coatings to extend lifespan in out of doorways use.

Winner: Tie—Concrete Impregnated Fabric for standard out of doorways durability; FRP for extreme chemical environments.

3. Installation and Versatility

Concrete Impregnated Fabric:

Speed: Instant Concrete Mat hydrates with water, curing in 24 hours—no mixing or heavy equipment needed. This makes it best for emergency repairs (e.g., avenue potholes or leaking dams).

Versatility: A Flexible Concrete Blanket can be decrease to size, wrapped spherical pipes, or draped over slopes, adapting to tricky geometries.

FRP:

Molding Requirements: FRP requires prefabrication in molds or on-site lamination with resins, which is time-consuming and weather-dependent (resins treatment poorly in cold or humid conditions).

Weight: While lightweight, FRP panels require cranes for set up on massive structures, developing labor costs.

Winner: Concrete Impregnated Fabric for pace and adaptability.

4. Cost and Maintenance

Concrete Impregnated Fabric:

Initial Cost: Lower than FRP, typically for large-area functions (e.g., slope stabilization with Flexible Concrete Blanket).

Maintenance: Minimal—cracks can be patched with greater Cement Impregnated Fabric, retaining off costly replacements.

FRP:

Initial Cost: Higher due to raw supplies (glass fibers, uniqueness resins) and fabrication complexity.

Maintenance: Repairs require specialised resins and specialist labor, driving long-term expenditures up—especially for damaged structural components.

Winner: Concrete Impregnated Fabric for cost-effectiveness.

5. Ideal Applications

Concrete Impregnated Fabric:

Emergency repairs (roads, pipelines).

Slope security and erosion control.

Canal, pond, or reservoir liners.

Temporary constructions (flood barriers) the utilization of Instant Concrete Mat.

FRP:

Industrial chemical tanks and piping.

Structural elements (beams, cladding) in corrosive environments.

Marine functions (boat hulls, docks) the region saltwater resistance is critical.

Conclusion: Choosing the Right Material

Neither material is universally “better”—the choice depends upon on your project’s priorities:

Choose Concrete Impregnated Fabric (or its variations like Instant Concrete Mat, Flexible Concrete Blanket, or Cement Impregnated Fabric) for rapid installation, flexibility, backyard durability, and cost-sensitive projects.

Choose FRP for immoderate tensile strength, extreme chemical resistance, and eternal load-bearing constructions in managed environments.

By aligning material houses with your project’s demands—whether speed, strength, or environmental resilience—you’ll make positive long-lasting, less expensive results.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province