Common Installation Mistakes to Avoid with HDPE Geomembrane

Introduction: The Critical Role of Proper HDPE Geomembrane Installation

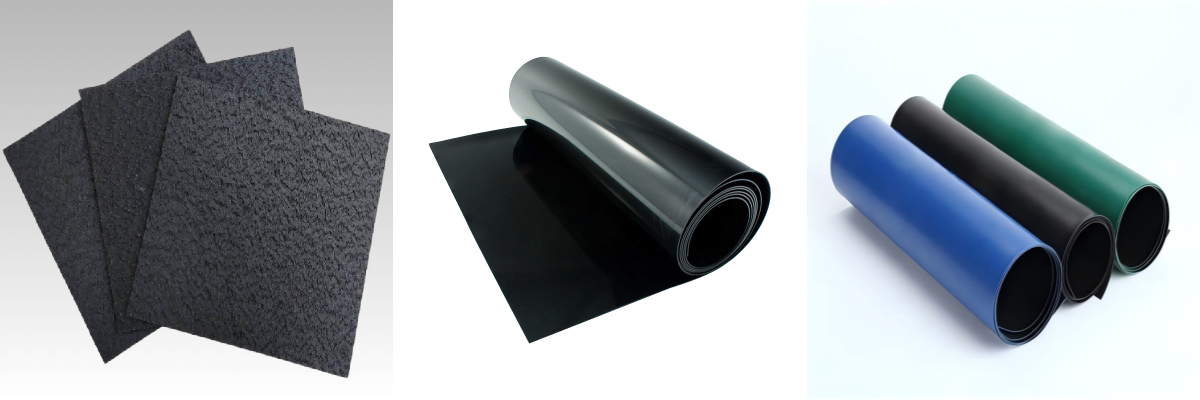

HDPE geomembrane is a high-performance impermeable geomembrane extensively used in landfill liners, water containment systems, and environmental remediation projects. As a key component, the hdpe geomembrane liner depends on particular set up to make sure its impermeability and durability. Even minor mistakes for the duration of set up can compromise its effectiveness, main to leaks, structural failures, and highly-priced repairs. This information highlights frequent errors to avoid, assisting specialists maximize the overall performance of hdpe geomembrane in their projects.

Mistake 1: Inadequate Site Preparation

Skipping Surface Cleaning

One of the most normal mistakes is putting in hdpe geomembrane over an unprepared surface. Rocks, debris, or sharp objects below the liner can puncture the material, negative its impermeable properties. Before laying, the web page need to be entirely cleared of all sharp particles, vegetation, and uneven surfaces. A smooth, compacted base ensures the hdpe geomembrane liner lies flat, lowering stress factors that may want to lead to tears.

Ignoring Soil Compaction

Loose or uncompacted soil is every other hazard. When the floor shifts, it creates wrinkles or gaps in the hdpe geomembrane, permitting water to seep through. Proper compaction of the subgrade—using rollers or vibrating equipment—stabilizes the surface, offering a stable basis for the impermeable geomembrane.

Mistake 2: Improper Handling and Storage

Folding Instead of Rolling

HDPE geomembrane is touchy to creases. Folding the cloth throughout storage or transport can create everlasting susceptible spots, making it susceptible to cracking. Always save and deal with hdpe geomembrane in rolls, securing them to stop unrolling. This preserves the integrity of the hdpe geomembrane liner, making sure uniform electricity throughout its surface.

Exposing to Extreme Conditions

Leaving hdpe geomembrane uncovered to direct daylight for prolonged durations hurries up UV degradation. While pleasant hdpe geomembrane is UV-resistant, extended publicity earlier than set up weakens its structure. Store rolls in shaded areas or cowl them with UV-protective tarps. Similarly, keep away from putting in in freezing temperatures, as bloodless makes the fabric brittle and more difficult to weld.

Mistake 3: Incorrect Laying Techniques

Poor Alignment and Overlapping

Inconsistent overlapping of hdpe geomembrane panels is a most important issue. Insufficient overlap (less than the endorsed 10–15 cm) reduces the effectiveness of welded seams, growing leak risks. Conversely, immoderate overlap wastes cloth and creates useless bulges. Follow producer hints for overlap lengths, making sure every panel aligns tightly with the subsequent to hold the impermeable geomembrane barrier.

Ignoring Slope and Tension

On sloped surfaces, failing to control anxiety can purpose the hdpe geomembrane liner to slide or sag. Over-tightening stretches the material, whilst under-tightening leads to wrinkles that lure water. Use anchoring structures at the pinnacle of slopes and modify anxiety progressively as the liner is unrolled, making sure a smooth, invulnerable suit that follows the contour of the surface.

Mistake 4: Faulty Welding Practices

Inconsistent Heat and Pressure

Welding is the spine of hdpe geomembrane installation, as seams are the most susceptible points. Using improper warmth or strain for the duration of extrusion or warm wedge welding creates susceptible bonds. Too little warmness consequences in incomplete fusion, whilst immoderate warmth melts the material, inflicting holes. Regularly calibrate welding gear and check seams with strain or vacuum assessments to confirm integrity.

Skipping Seam Inspections

Even with acceptable welding, seams can fail due to dust, moisture, or particles trapped between panels. Skipping post-weld inspections is a vital error. Visually test each seam for gaps or irregularities, and use non-destructive trying out strategies (like air strain testing) to notice hidden leaks. Addressing problems right away prevents expensive repairs later.

Mistake 5: Neglecting Post-Installation Protection

Allowing Traffic on Uncovered Liner

After installation, the hdpe geomembrane liner is inclined to harm from heavy tools or foot traffic. Failing to shield it with a layer of soil, geotextile, or different cowl substances can lead to punctures. Restrict get admission to to the vicinity till protecting layers are in place, and mark the liner’s region to forestall unintended harm all through subsequent construction.

Ignoring Environmental Factors

Exposure to chemicals, intense temperatures, or organic increase can degrade hdpe geomembrane over time. In industrial sites, make certain the liner is like minded with saved substances. In out of doors projects, display for signs and symptoms of UV injury or root intrusion, and tackle troubles at once to preserve the impermeable geomembrane’s performance.

Conclusion: Ensuring Longevity with Proper Installation

Avoiding these common errors is fundamental for maximizing the lifespan and effectiveness of hdpe geomembrane. From thorough website online guidance to specific welding and post-installation protection, each and every step influences the overall performance of the impermeable geomembrane. By prioritizing cautious handling, following producer guidelines, and conducting rigorous inspections, authorities can make sure their hdpe geomembrane liner presents reliable, long-term safety in any application. Investing time in suited set up eventually saves resources, prevents environmental risks, and ensures the success of your project.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province