Cement Blankets for Slope Stabilization: A Cost-Effective Solution

Slope stabilization is a vital problem in construction, infrastructure maintenance, and environmental protection. Unstable slopes can lead to landslides, erosion, and harm to roads, buildings, and herbal ecosystems. For years, enterprise gurus have relied on standard techniques like poured concrete, stone masonry, and soil nailing, however these processes frequently come with excessive costs, lengthy set up times, and confined adaptability. Today, a progressive answer has emerged to tackle these challenges: cement blanket (also regarded as concrete material or cement canvas). This versatile fabric is reworking slope stabilization projects, providing a cost-effective, efficient, and long lasting choice to traditional techniques.

1. What Are Cement Blankets, Concrete Cloth, and Cement Canvas?

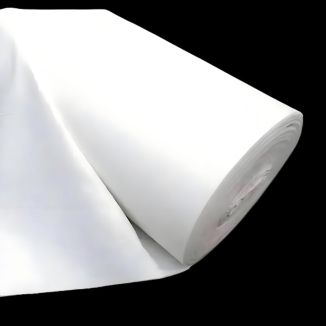

Before diving into their purposes for slope stabilization, it’s fundamental to recognize what cement blanket, concrete cloth, and cement canvas are—and why they’re frequently used interchangeably. At their core, these substances are flexible, prefabricated sheets composed of three key layers: a long lasting outer material (typically made of polypropylene or polyester), a center layer of dry concrete combine (containing cement, aggregates, and additives), and a water-resistant internal membrane.

The magic of cement blanket lies in its simplicity: when uncovered to water (either via rainfall or guide watering), the dry concrete combine hydrates and cures, reworking the bendy material into a rigid, concrete-like structure. This special property ability concrete material can be transported and mounted in a lightweight, foldable state—eliminating the want for heavy gear to combine and pour moist concrete on-site. Similarly, cement canvas retains this flexibility in the course of installation, permitting it to conform to the herbal contours of slopes, even in irregular or hard-to-reach areas.

Unlike standard concrete, which requires unique mixing ratios and cautious pouring to keep away from cracks, cement blanket is factory-manufactured to steady high-quality standards. This ensures uniform energy and overall performance throughout the whole sheet, decreasing the chance of susceptible factors that may want to compromise slope stability. Whether referred to as cement blanket, concrete cloth, or cement canvas, this cloth provides a streamlined method to developing strong, erosion-resistant boundaries on slopes.

2. Key Advantages of Using Cement Blankets for Slope Stabilization

When it comes to slope stabilization, cement blanket stands out for its array of advantages that tackle the obstacles of standard methods. Below are the most sizable blessings that make concrete material and cement canvas a pinnacle desire for engineers, contractors, and mission managers.

2.1 Fast and Easy Installation

One of the largest drawbacks of ordinary concrete is its time-consuming set up process: it requires transporting uncooked substances (cement, sand, water), mixing on-site, and pouring into forms—all of which can take days, even for small projects. Cement blanket, by way of contrast, arrives geared up to use. Workers can unroll concrete fabric immediately onto the slope, impervious it with anchors or stakes, and spark off the curing method with water. This reduces set up time by way of up to 70% in contrast to poured concrete, making cement canvas perfect for emergency slope repairs (e.g., after heavy rains or storms) or initiatives with tight deadlines.

2.2 Adaptability to Irregular Slopes

Slopes in real-world settings not often have smooth, uniform surfaces—they may also function rocks, vegetation, or uneven terrain. Traditional strategies like concrete slabs or maintaining partitions battle to conform to these irregularities, main to gaps that can enable water infiltration and erosion. Cement blanket, however, is quite bendy earlier than curing. It can be reduce to size, folded round obstacles, and pressed into the slope’s contours, making sure full contact with the ground. This adaptability capability concrete fabric creates a seamless barrier that prevents water from seeping underneath the surface, a essential thing in long-term slope stability. Even on steep slopes (up to 60 degrees), cement canvas stays impervious throughout set up and curing, removing the want for complicated formwork.

2.3 Durability and Resistance to Environmental Stress

Slopes are uncovered to harsh environmental conditions: heavy rainfall, severe temperatures, UV radiation, and soil movement. Cement blanket is designed to face up to these stresses. Once cured, it types a dense, inflexible shape with a compressive electricity similar to ordinary concrete (up to 20 MPa). The outer cloth of concrete fabric additionally acts as a shielding layer, resisting UV injury and stopping the increase of weeds that ought to weaken the slope. Unlike soil erosion manipulate mats (which degrade over time) or stone partitions (which can shift or crack), cement canvas has a lifespan of 20+ years with minimal maintenance. It additionally resists chemical corrosion, making it appropriate for slopes close to industrial web sites or coastal areas the place saltwater would possibly harm different materials.

2.4 Cost Savings Across the Project Lifespan

Cost-effectiveness is a key motive why cement blanket is gaining reputation for slope stabilization. Let’s ruin down the savings:

Material Costs: While the upfront fee of cement blanket can also be barely greater than primary erosion control products, it eliminates the want for extra substances like formwork, reinforcement bars, or extra concrete (which regularly goes to waste in regular projects).

Labor Costs: Installing concrete fabric requires fewer employees and no specialised capabilities (unlike pouring concrete, which wishes educated masons). This reduces labor costs via 30–50%.

Maintenance Costs: As mentioned, cement canvas requires little to no protection over its lifespan, heading off the ongoing charges of repairing cracks, changing eroded sections, or casting off weeds.

When in contrast to usual methods, cement blanket normally reduces whole assignment expenses by way of 20–40%—a large saving for both small-scale repairs and giant infrastructure projects.

3. Common Applications of Cement Blankets in Slope Stabilization

Cement blanket, concrete cloth, and cement canvas are versatile ample to take care of a broad vary of slope stabilization scenarios. Below are the most frequent functions the place these substances supply exquisite results.

3.1 Road and Highway Slopes

Roads and highways frequently reduce via hillsides, growing steep slopes that are susceptible to erosion and landslides. Even minor slope motion can lead to street closures, delays, and security hazards. Cement blanket is an best answer here: it can be shortly established alongside street embankments to stop soil erosion prompted by way of rainfall or visitors vibration. The flexibility of concrete fabric lets in it to comply with the curve of the road, whilst its cured tension protects the slope from washouts. For example, in rural areas the place get right of entry to is limited, cement canvas can be transported by means of truck and unrolled via a small team, fending off the want for heavy concrete mixers or cranes.

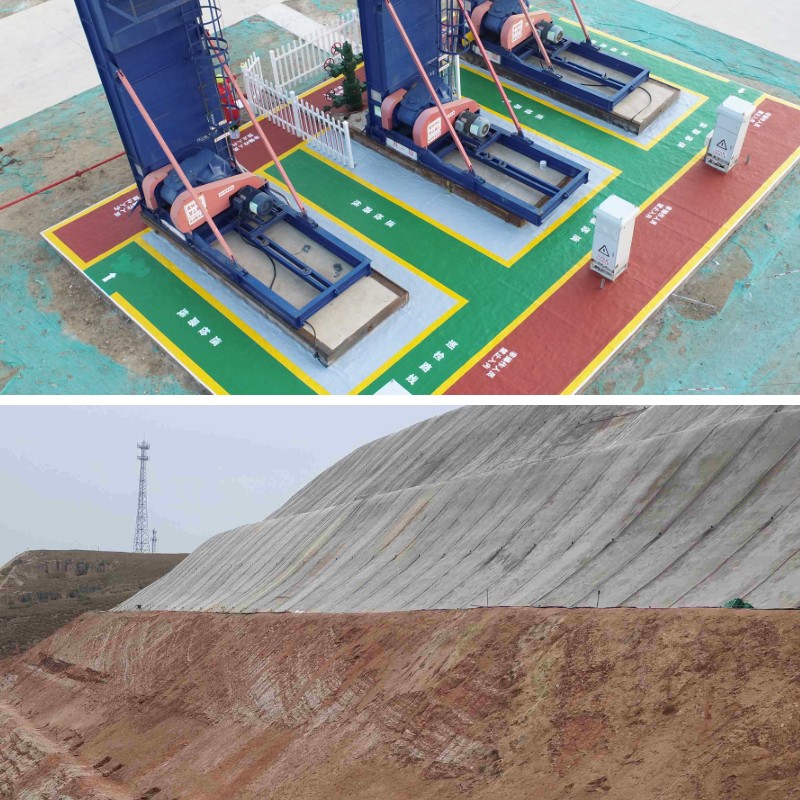

3.2 Mining and Quarry Slopes

Mining operations and quarries create large, unstable slopes that pose dangers to workers, equipment, and close by communities. These slopes are regularly uncovered to heavy equipment visitors and steady soil disturbance, making erosion a primary concern. Cement blanket presents a long lasting barrier that withstands the affect of mining activities. It can be utilized to each lively and deserted mine slopes: on energetic sites, concrete material protects slopes from dirt and debris; on deserted sites, it helps stabilize the soil for reforestation or land rehabilitation. The speedy set up of cement canvas additionally minimizes downtime for mining operations, retaining initiatives on schedule.

3.3 River and Coastal Slopes

Riverbanks and coastal slopes face special challenges: regular water exposure, wave action, and tidal erosion. Traditional strategies like stone riprap (large rocks) can be fine however are luxurious to transport and install. Cement blanket gives a lighter, greater cost-efficient alternative. When hooked up alongside riverbanks, concrete material acts as a water resistant barrier, stopping river water from seeping into the slope and inflicting erosion. Along coastlines, cement canvas resists saltwater corrosion and wave impact, defending coastal communities from landslides and flooding. Its flexibility additionally permits it to modify to minor soil motion precipitated by means of tides, lowering the danger of cracking.

3.4 Construction Site Slopes

Construction websites regularly require transient or everlasting slope stabilization to shield people and equipment. For example, excavating a constructing basis creates steep trenches with unstable slopes that can cave in if no longer secured. Cement blanket is ideal for this scenario: it can be hooked up rapidly to stabilize the trench partitions for the duration of construction, then left in region as a everlasting barrier if needed. The light-weight nature of concrete fabric skill it can be transported round the development website online easily, even in tight spaces. Unlike brief erosion manipulate mats, cement canvas doesn’t want to be changed midway thru the project, saving time and money.

4. How to Install Cement Blankets for Slope Stabilization

Installing cement blanket (or concrete cloth/cement canvas) is a easy procedure that requires minimal gear and training. Below is a step-by-step information to make certain a profitable set up for slope stabilization.

4.1 Site Preparation

Before putting in cement blanket, put together the slope to make sure best adhesion and performance:

Clear Debris: Remove rocks, roots, and free soil from the slope. Any boundaries ought to create gaps between the concrete material and the ground, permitting water infiltration.

Smooth the Surface: Rake the slope to create a noticeably clean surface. Minor unevenness is k (thanks to the flexibility of cement canvas), however giant bumps or holes have to be stuffed with compacted soil.

Assess Drainage: Ensure the slope has applicable drainage to forestall water from pooling under the cement blanket. If needed, deploy drainage pipes or channels earlier than laying the material.

4.2 Measuring and Cutting the Cement Blanket

Measure the size and width of the slope to decide how a good deal cement blanket is needed. Most concrete material comes in rolls of 2–5 meters extensive and 10–20 meters long, however it can be reduce to measurement the use of a utility knife or scissors. When cutting, depart a 5–10 cm overlap between adjoining sheets to create a seamless joint. This overlap prevents water from seeping thru the gaps between sheets.

4.3 Laying and Securing the Cement Blanket

Unroll the cement blanket from the pinnacle of the slope to the bottom, making sure it lies flat in opposition to the ground. Avoid stretching the material, as this ought to reason it to crack at some point of curing. Secure the concrete fabric to the slope the use of anchors, stakes, or rebar:

Top Edge: Drive anchors into the floor at the pinnacle of the slope to maintain the cement canvas in place. This prevents it from sliding down at some point of set up or curing.

Edges and Joints: Secure the facets of the cement blanket with stakes each and every 1–2 meters. For overlapping sheets, use stakes to pin the overlapping part to the slope, making sure a tight seal.

Bottom Edge: Bury the backside area of the concrete material in a shallow trench (10–15 cm deep) and backfill with soil. This anchors the cloth and prevents water from flowing underneath.

4.4 Curing the Cement Blanket

Once the cement blanket is secured, it’s time to prompt the curing process. Use a backyard hose, sprinkler, or water truck to completely moist the complete floor of the concrete cloth. The aim is to saturate the fabric evenly—avoid overwatering (which can wash away the concrete mix) or underwatering (which can lead to incomplete curing).

The curing time relies upon on environmental conditions: in warm, dry weather, cement canvas will therapy in 24–48 hours; in cool or humid weather, it may also take 3–5 days. During curing, keep away from on foot on the cement blanket or exposing it to heavy rain (which can disrupt the concrete mix). Once utterly cured, the cloth will be inflexible and prepared to face up to environmental stress.

4.5 Post-Installation Inspection

After curing, investigate the cement blanket to make certain it’s exact installed:

Check for cracks, gaps, or unfastened sections. If any problems are found, patch them with a small piece of concrete fabric (cut to size, wetted, and pressed into place).

Verify that drainage structures are working correctly, with no water pooling underneath the cement canvas.

Monitor the slope for the first few weeks after installation, specifically after heavy rain, to make certain the cement blanket stays stable.

5. Why Cement Blankets Are the Future of Slope Stabilization

As the building and infrastructure industries shift towards extra sustainable, cost-effective, and environment friendly solutions, cement blanket, concrete cloth, and cement canvas are rising as the future of slope stabilization. Here’s why:

First, they align with international sustainability goals. Traditional concrete manufacturing is a fundamental supply of carbon emissions (accounting for ~8% of international CO₂ output). Cement blanket makes use of much less concrete per rectangular meter (thanks to its light-weight design) and reduces fabric waste (since it’s pre-cut to size). Additionally, the outer cloth of concrete material is frequently made from recycled materials, similarly decreasing its environmental footprint.

Second, they address the developing want for speedy infrastructure repair. With local weather alternate main to greater widely wide-spread excessive climate occasions (e.g., hurricanes, floods), the capability to rapidly stabilize slopes and forestall injury is critical. Cement canvas can be set up in hours, no longer days, making it an vital device for emergency response teams.

Finally, they provide long-term value. While some more cost-effective erosion manage merchandise may additionally appear attractive upfront, they frequently want to be changed each and every 2–5 years. Cement blanket has a lifespan of 20+ years, which means it affords higher return on funding over time. For municipalities, building companies, and landowners, this long-term sturdiness interprets to fewer complications and decrease costs.

Conclusion

Slope stabilization doesn’t have to be expensive, time-consuming, or inflexible. Cement blanket (also recognised as concrete material or cement canvas) presents a game-changing answer that combines speed, adaptability, durability, and cost-effectiveness. Whether you’re stabilizing a street embankment, a mining slope, a riverbank, or a development site, cement blanket can provide consequences that usual techniques can’t match.

By deciding on cement blanket for your slope stabilization project, you’re now not simply saving time and money—you’re investing in a sustainable, long-lasting answer that protects people, infrastructure, and the environment. As extra enterprise gurus find out the advantages of this revolutionary material, concrete material and cement canvas will proceed to come to be the go-to preference for slope stabilization worldwide.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province