Common Geotextile Installation Mistakes and How to Avoid Them

Introduction: The Critical Role of Proper Geotextile Installation

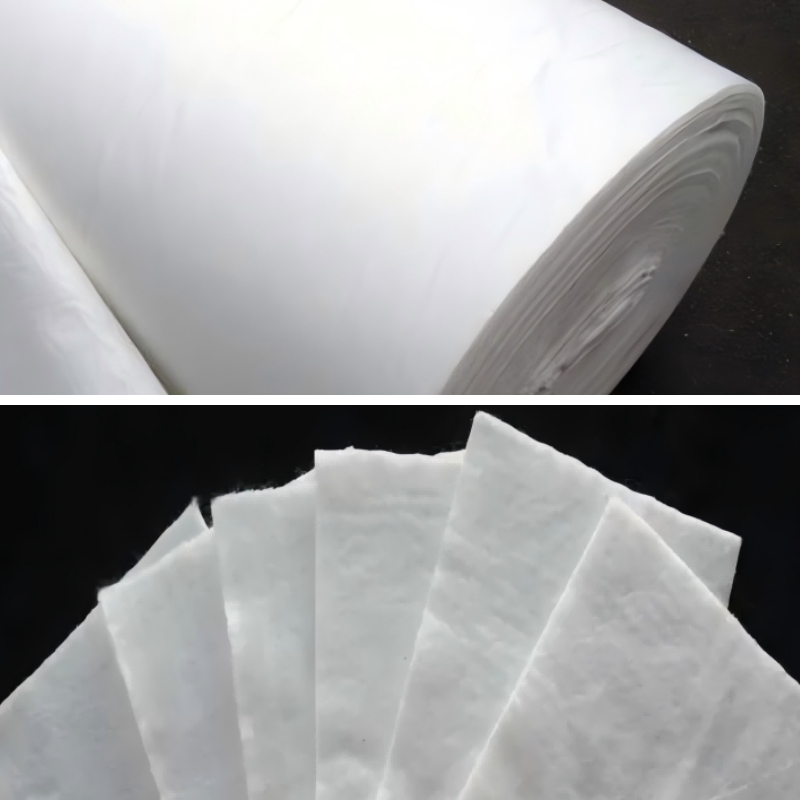

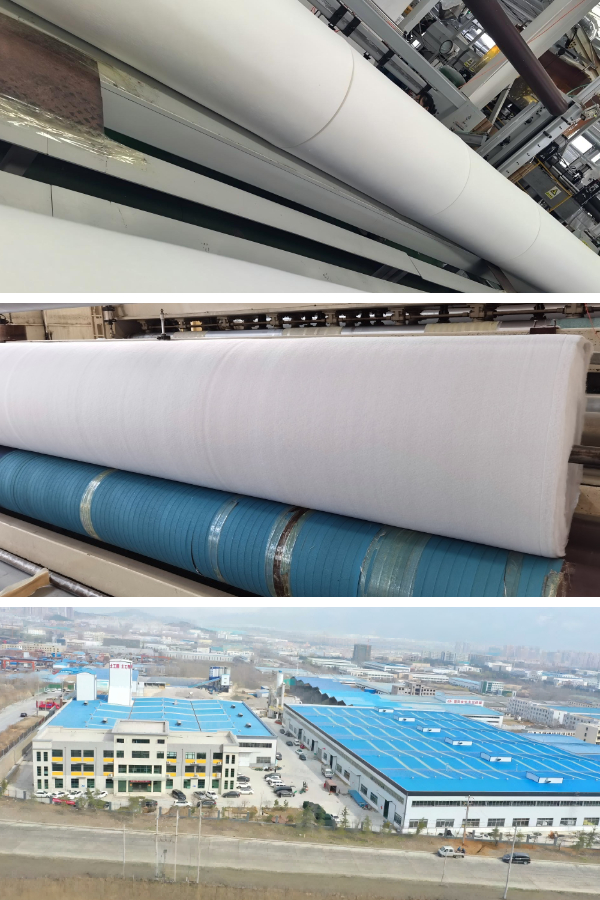

Geotextiles, in addition known as geo fabric materials, are engineered workhorses in modern construction. They supply essential functions like separation, filtration, drainage, and reinforcement. However, the performance of any geotextile is absolutely as good as its installation. A perfectly specified geo cloth can be rendered useless by simple, preventable errors in the field. These error lead to project delays, cost overruns, and ultimately, structural failure. This comprehensive statistics delves into the most frequent geotextile installation blunders and affords actionable methods to avoid them, ensuring your geo material fabric delivers its intended advantages for the life of the project.

Mistake 1: Inadequate Site Preparation

The foundation of any successful set up is a well-prepared subgrade. Rushing this stage is the first and most critical error.

The Problem: Installing a geo cloth on a subgrade that is uneven, littered with debris, or contains vegetation will create a host of issues. Sharp rocks, roots, and stumps can puncture or tear the material during set up or underneath load. An uneven floor prevents intimate contact between the geotextile and the soil, creating voids. Under the weight of overlying aggregate, the cloth can stretch into these voids, main to stress concentrations and viable rupture.

How to Avoid It:

Clear and Grade: Remove all vegetation, roots, rocks, and construction debris. The subgrade ought to be clear of any sharp objects that could act as stress points.

Grade to Specification: Grade the soil to the required design profile. The goal is a uniform, compacted floor that allows the geo cloth material to lie flat and easy without anxiousness or wrinkles.

Compact Properly: Ensure the subgrade is properly compacted to stop future settlement that must strain the overlying geotextile.

Mistake 2: Incorrect Geotextile Orientation and Side Placement

Not all geotextiles are created equal, and many have a precise "right side up."

The Problem: Some geo fabric materials, particularly non-wovens used for filtration, have a easy and a fuzzy side. Installing them upside down can severely hinder their performance. Placing the easy side towards the soil can reduce the filtration effectivity and interface friction, main to clogging or slippage. Furthermore, confusing a woven geotextile (designed for reinforcement) with a non-woven geotextile (designed for filtration) for the duration of set up is a catastrophic error that compromises the entire sketch intent.

How to Avoid It:

Consult the Manufacturer: Always check the manufacturer's data sheet for the recommended orientation. As a familiar rule for non-wovens, the smoother side generally faces the finer soil to optimize filtration.

Understand the Function: Be absolutely clear on the principal function of the geo fabric in your application. Is it for separation and reinforcement (typically woven) or for filtration and drainage (typically non-woven)? This ensures the correct geo cloth material is on net site and mounted correctly.

Mark the Rolls: If the orientation is critical, use a marker to indicate the "up" aspect on the roll earlier than deployment.

Mistake 3: Poor Seaming and Overlap Techniques

A geotextile ought to act as a continuous barrier or reinforcement layer. Inadequate seams are a frequent factor of failure.

The Problem: Simply butting rolls of geo cloth together or offering an inadequate overlap creates a vulnerable seam. Soil can migrate through the gap, or the layers can separate below load, rendering the geotextile ineffective. This is a essential reason of aggregate illness and subgrade failure.

How to Avoid It:

Provide Sufficient Overlap: The widespread minimal overlap is typically 12 to 18 inches (300 to 450 mm) for most applications. However, this can fluctuate based totally on subgrade prerequisites and the precise geo fabric material. Always observe the task specifications.

Sew or Pin Seams on Slopes: On slopes or in high-stress applications, overlapping by myself may no longer be sufficient. Seaming the geotextile with a specialized stitching desktop or the usage of mechanical pins along the overlap is integral to forestall slippage.

Align Overlap Correctly: When overlapping, continually align the rolls so that the upstream roll lies on top of the downstream roll relative to the course of water flow. This prevents water from getting under the geo cloth and lifting it.

Mistake 4: Damage During Backfilling and Lack of Protection

The installation procedure isn't always over as soon as the geotextile is placed. The most subtle phase begins: backfilling.

The Problem: Dropping large, sharp mixture at once from a good sized height onto the geo material will inevitably purpose punctures and tears. Similarly, monitoring over the unprotected fabric with heavy equipment can rip it or push it into the tender subgrade.

How to Avoid It:

Use a Initial Lift of Material: Place a initial, skinny layer (e.g., 6 inches) of fine, screened, or rounded material by means of spreading it from the edges inward. This preliminary layer cushions the geotextile.

Control Drop Heights: Limit the drop top when placing backfill material. Ideally, the first lift have to be positioned with a low-volume conveyor or cautiously dumped from a low bucket height.

Avoid Equipment on Unprotected Fabric: Never drive gear at once on the uncovered geo fabric material. If crossing is certainly necessary, first region a thick, defensive layer of granular material. Always use tracked equipment over rubber-tired vehicles, as they distribute the load extra evenly.

Mistake 5: Improper Tensioning and Wrinkling

A wrinkled geotextile is a compromised geotextile.

The Problem: Installing a geo cloth with immoderate wrinkles or folds is detrimental. These wrinkles create pockets where the material is now not in contact with the soil, main to uneven stress distribution. When aggregate is positioned and compacted, the material is compelled to stretch taut, often ensuing in tears at the base of the folds.

How to Avoid It:

Deploy Smoothly: Unroll the geotextile along the course of installation, permitting it to lie flat and relaxed. Do no longer pull it taut, as this can induce unwanted tension.

Smooth Out Wrinkles: As you unroll, stroll on the cloth to easy out any minor wrinkles that form. For larger areas, a light-weight drag or pull-behind smoother can be used.

Secure with Staples: Use U-shaped panorama staples or pins on slopes and in windy conditions to maintain the geo fabric cloth in place, preventing it from moving or billowing before and at some stage in backfilling.

Conclusion: Building on a Solid Fabric Foundation

A geotextile is a precision-engineered material, now not just a easy roll of cloth. Its long-term overall overall performance is inextricably linked to the care taken at some stage in its installation. By avoiding these common mistakes—poor internet web page prep, incorrect orientation, inadequate seaming, backfill damage, and improper tensioning—you make certain that your chosen geo fabric material performs its critical factors effectively.

Investing time and attention in correct installation practices is no longer an extra cost; it is an insurance policy that ensures the integrity, durability, and cost-effectiveness of your entire project. Always refer to mission specifications and producer guidelines, and ensure that field personnel are actual skilled in handling and installing this fundamental building component. A correctly installed geotextile is the unseen hero that ensures the stability and sturdiness of the structures we build upon it.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province