Why Composite Geomembranes are the Gold Standard for Landfill Liners and Caps

The present day landfill is a feat of environmental engineering, a meticulously designed containment system whose primary goal is to guard the surrounding ecosystem from contamination. At the heart of this system lies a critical component: the liner and cap. While single-layer substances have been used in the past, the industry has unequivocally moved towards a more sturdy and reliable solution. The Composite Geo-membrane, particularly the HDPE Composite Geomembrane, has emerged as the undisputed gold standard for these applications. This article explores the engineering brilliance at the again of this material and why it is the preferred choice for safeguarding our soil and groundwater.

The Landfill Challenge: A Battle Against Leachate and Gas

A landfill is a dynamic, chemically aggressive environment. As waste decomposes, it generates a poisonous soup known as leachate, which can contain heavy metals, volatile natural compounds, and pathogens. Simultaneously, decomposition gases like methane create internal pressures. The liner system at the base must forestall leachate from migrating into the subsoil, while the cap system on top ought to quit water infiltration and gas escape. A single point of failure can lead to an environmental disaster. This is the place the multi-layered safety of a composite geotextile and geomembrane system proves its worth.

What is a Composite Geomembrane? Deconstructing the Design

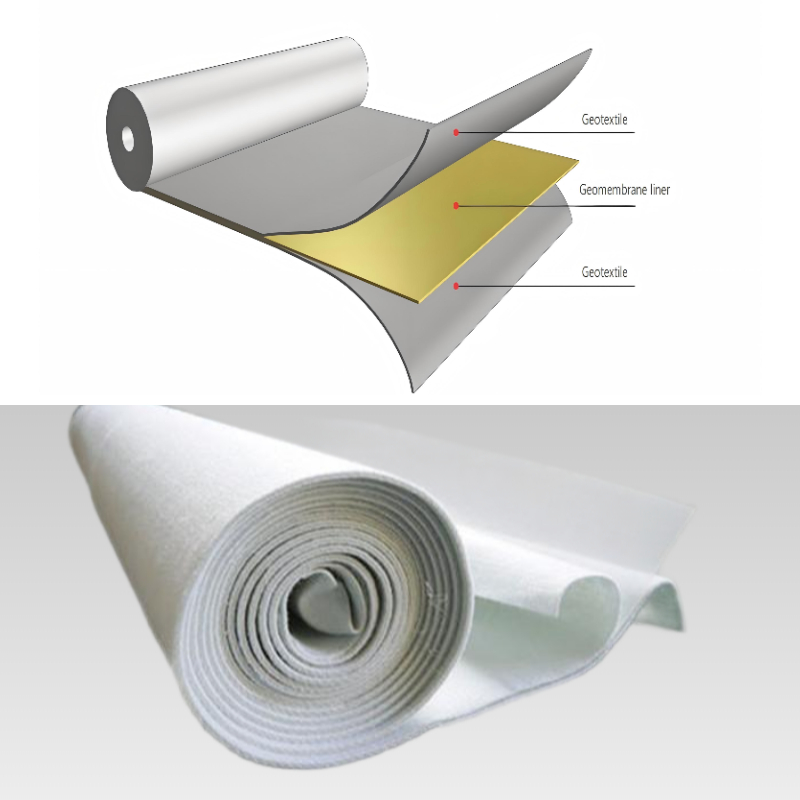

A Composite Geo-membrane is an engineered material that combines the nice residences of two wonderful geosynthetics into a single, high-performance product. It is typically a laminated shape consisting of:

A Geomembrane Film: This is the impermeable barrier, most regularly made from High-Density Polyethylene (HDPE). The HDPE Composite Geomembrane is famend for its exceptional chemical resistance, durability, and low permeability.

A Geotextile Layer: This is a non-woven, needle-punched material thermally bonded to one or each facets of the geomembrane. This layer creates the composite geotextile functionality.

The synergy between these layers is what sets the composite apart. The geomembrane offers the fluid barrier, whilst the composite geotextile layer offers crucial mechanical protection, drainage capacity, and improved interface friction.

Key Advantages of Composite Geomembranes in Landfill Liners

The base liner is the closing line of defense in opposition to groundwater contamination. The Composite Geo-membrane excels right right here for a number of critical reasons.

1. Superior Puncture and Tensile Strength

The subgrade of a landfill is never flawlessly smooth. Even with cautious preparation, sharp rocks or debris can pose a threat. A standalone HDPE geomembrane can be prone to puncture in the course of set up or from long-term stress. The integrated composite geotextile layer acts as a cushion, absorbing and distributing point stresses. This dramatically will enlarge the puncture resistance of the whole system, ensuring the integrity of the impermeable HDPE Composite Geomembrane core is maintained.

2. Enhanced Interface Shear Strength

Landfill slopes must be stable. The textured ground supplied by the composite geotextile layer significantly will amplify the friction attitude between the geomembrane and the adjacent soil or geosynthetic layers (like geonets). This high interface shear strength prevents slippage and sloughing on steep slopes, a quintessential factor for the long-term structural stability of the landfill cell.

3. Built-In Protection and Drainage

In a composite liner system, the Composite Geo-membrane frequently sits atop a compacted clay liner. The non-woven geotextile aspect facing the clay allows for the venting of any trapped gases or moisture between the two low-permeability layers, stopping the formation of damaging stress bubbles. This built-in safety layer is imperative to the product, simplifying installation and improving performance.

The Critical Role of Composites in Landfill Caps and Closures

Once a landfill cellphone reaches capacity, it ought to be capped to minimize long-term environmental impact. The cap system features as a "raincoat," minimizing leachate science by shedding water. The HDPE Composite Geomembrane is equally vital in this application.

1. Effective Barrier Against Infiltration

The HDPE layer in the cap acts as an impermeable barrier, stopping rainfall and floor water from percolating thru the waste mass. This is the most effective way to limit future leachate era and remedy costs.

2. A Stable Platform for the Final Cover

The composite geotextile layer on the cap-side Composite Geo-membrane provides an top notch interface for the overlying drainage geocomposites and topsoil. The excessive friction floor prevents cover soil slippage, specially on the aspect slopes, advertising vegetation growth and making sure the long-term integrity of the last cowl system.

Why HDPE is the Preferred Choice for the Barrier Layer

While composites can be made with various geomembranes, HDPE Composite Geomembrane merchandise are the most extensively specified for landfills. The motives are rooted in HDPE's unmatched cloth properties:

Exceptional Chemical Resistance: HDPE is inert to the huge range of aggressive chemical compounds determined in leachate, making sure the barrier does not degrade over decades.

Excellent Durability: HDPE provides finest resistance to ultraviolet (UV) radiation for the duration of installation and has a tested long-term carrier existence in buried applications.

Low Permeability: HDPE has an extremely low hydraulic conductivity, effectively growing a barrier that is as impermeable as many natural clays, but much thinner and greater consistent.

Installation Considerations for Optimal Performance

The most excellent engineering of a Composite Geo-membrane can only be realized with proper installation. Key satisfactory practices include:

Subgrade Preparation: The foundation must be smooth, compacted, and free of sharp objects to prevent unduly stressing the material.

Panel Seaming: Seams between adjacent rolls are the most quintessential points. They have to be made using specialized thermal fusion welding tools operated thru certified technicians to create a continuous, monolithic barrier.

Anchor Trenches: The material ought to be securely anchored in perimeter trenches to prevent wind uplift for the length of installation and long-term subsidence.

Protection Layer: While the composite geotextile affords built-in protection, a layer of sand or a protective geotextile is often placed over the liner earlier than waste placement begins for added security.

Conclusion: An Investment in Long-Term Environmental Protection

Choosing a lining system for a landfill is a choice with consequences that span generations. While initial fee is a factor, the long-term fee of failure—environmental damage, regulatory fines, and astronomical remediation expenses—is infinitely greater. The Composite Geo-membrane, particularly the HDPE Composite Geomembrane, represents the pinnacle of containment technology. By combining the impermeability of HDPE with the mechanical benefits of a composite geotextile, it guarantees a robust, durable, and pretty reliable solution. It is not truly a product; it is a dedication to responsible waste management and enduring environmental stewardship. For any modern landfill project, specifying a composite geomembrane is now no longer simply a best practice—it is the essential enormous for success.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province