Case Studies: Successful HDPE Geomembrane Use in Mining Tailings Storage

Introduction: The Critical Role of Geomembrane in Mining Safety

Mining tailings—waste substances left after mineral extraction—often comprise heavy metals, acids, and poisonous chemicals. Without impervious containment, these resources can leach into soil and waterways, inflicting irreversible environmental damage. High density polyethylene geomembrane (HDPE) has grow to be a cornerstone of accountable mining, imparting unparalleled safety via its strong shape and geomembrane waterproofing capabilities. Below are three case research showcasing its success in real-world tailings storage projects.

Why HDPE Geomembrane Stands Out for Tailings Storage

High density polyethylene geomembrane is uniquely desirable to mining’s harsh demands. Its key blessings include:

Superior Chemical Resistance: Withstands corrosive factors like sulfuric acid and heavy metals frequent in tailings.

Exceptional Impermeability: Delivers industry-leading geomembrane waterproofing (permeability as low as 1×10⁻¹² cm/s), stopping poisonous leaks.

Durability: UV-stabilized and tear-resistant, it endures intense temperatures, heavy loads, and many years of publicity to harsh conditions.

Cost-Effectiveness: Lower set up and preservation charges in contrast to concrete or clay liners, with a longer lifespan.

Case Study 1: Copper Mine Tailings Dam, Chile

Project Background

A giant copper mine in Chile’s Atacama Desert confronted a indispensable challenge: its getting old tailings dam, lined with clay, used to be leaking acidic water (pH 2–3) into the surrounding arid ecosystem. With strict environmental policies and a want for long-term stability, engineers selected 2mm excessive density polyethylene geomembrane to reline the 500-hectare facility.

Implementation

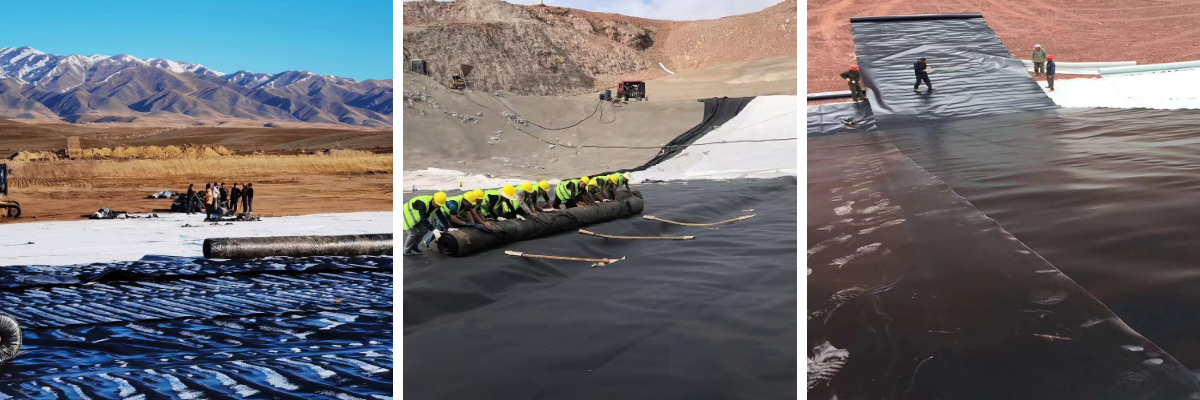

The set up crew laid the geomembrane over a non-woven geotextile cushion to forestall punctures from rocky soil. Seams have been heat-welded the use of computerized machinery, making sure a seamless barrier—critical for geomembrane waterproofing. Post-installation, each weld underwent vacuum checking out to confirm integrity.

Results (12 Years Later)

Zero Leaks: Water fantastic exams round the dam exhibit no hint of heavy metals or acids, confirming the geomembrane waterproofing effectiveness.

UV Resistance: Despite 3,000+ hours of annual sunlight, the excessive density polyethylene geomembrane retains 90% of its tensile strength, with no signs and symptoms of brittleness.

Cost Savings: Compared to the preceding clay liner (which required annual repairs), protection fees dropped through 70%, with no want for predominant overhauls.

Case Study 2: Gold Mine Tailings Pond, Canada

Project Background

A far off gold mine in northern Canada wanted to comprise cyanide-laden tailings—a poisonous byproduct of gold extraction—in a vicinity susceptible to freezing temperatures and heavy snowfall. The mine chosen 1.5mm excessive density polyethylene geomembrane for its flexibility in bloodless climates and resistance to cyanide degradation.

Implementation

Installation came about at some stage in a quick summer time window, with crews laying the geomembrane over a compacted clay subgrade to beautify stability. Welders labored in shifts to seal seams earlier than temperatures dropped, the usage of warmness weapons calibrated for cold-weather conditions. The liner was once additionally anchored with concrete weights alongside the pond’s perimeter to withstand ice expansion.

Results (8 Years Later)

Cold Weather Performance: The geomembrane withstood 40°C iciness lows except cracking, preserving its water resistant seal even as ice shifted.

Cyanide Compatibility: Lab evaluation of the liner indicates no chemical breakdown, proving excessive density polyethylene geomembrane’s resistance to cyanide.

Ecosystem Protection: Fish and flora and fauna surveys in nearby streams verify no cyanide contamination, assembly Canada’s strict environmental standards.

Case Study 3: Iron Ore Tailings Facility, Australia

Project Background

An iron ore mine in Western Australia wished to extend its tailings storage to cope with extended production. The site’s sandy soil and excessive rainfall made ordinary liners risky, so engineers opted for 2mm excessive density polyethylene geomembrane paired with a geotextile underlay for greater puncture resistance.

Implementation

The geomembrane used to be deployed in giant rolls to reduce seams, with automatic welding machines making sure consistent, sturdy bonds. A leak detection device used to be established under the liner to screen for breaches, with sensors related to a central dashboard for real-time alerts.

Results (6 Years Later)

Storm Resilience: The liner survived cyclonic rains (1,000mm in forty eight hours) with no water infiltration, thanks to its geomembrane waterproofing and invulnerable anchoring.

Abrasion Resistance: Even with consistent motion of iron ore tailings (abrasive via nature), the geomembrane indicates minimal floor wear, keeping its integrity.

Regulatory Compliance: The facility has handed each and every environmental audit, with regulators praising the excessive density polyethylene geomembrane as a mannequin for sustainable mining.

Key Lessons from Successful Projects

These case research spotlight satisfactory practices for excessive density polyethylene geomembrane use in mining tailings storage:

Seam Quality: Proper welding (heat-welded seams examined to a hundred percent strength) is quintessential for geomembrane waterproofing.

Subgrade Preparation: Pairing with geotextile or clay underlays prevents punctures from rocks or moving soil.

Climate Adaptation: Choose thickness (1.5–2mm) primarily based on nearby conditions—thicker liners for abrasive tailings or intense temperatures.

Monitoring: Leak detection structures add an more layer of safety, making sure early intervention if problems arise.

Conclusion: HDPE Geomembrane—A Trusted Solution for Mining

The success tales from Chile, Canada, and Australia show that excessive density polyethylene geomembrane is extra than a regulatory requirement—it’s a reliable, reasonably-priced answer for defending ecosystems and making sure mining longevity. Its geomembrane waterproofing capabilities, chemical resistance, and sturdiness make it the gold general for tailings storage.

For mining operations looking for to stability productiveness with environmental stewardship, geomembrane science gives a clear direction to success—one that stands the check of time, climate, and hard mining conditions.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province