Case Studies: Successful Geomat Projects and Their Impact on Construction Efficiency

In the development industry, effectivity at once affects undertaking timelines, costs, and long-term durability. Traditional techniques frequently conflict with challenges like soil instability, erosion, and labor-intensive processes—issues that geomat and superior options like 3D geomat have transformed. By integrating these geosynthetic materials, tasks global have decreased delays, reduce costs, and multiplied structural performance. Below are 4 real-world case research highlighting how geomat applied sciences pressure development efficiency, with actionable insights for enterprise professionals.

1. Foundation Stabilization: Geomat Cuts Timeline for a Urban Residential Complex

Weak or uneven soil is a pinnacle perpetrator for delayed basis work, specifically in dense city areas the place area and time are limited. A 2023 residential venture in Bangkok, Thailand, confronted this genuine challenge—and became to geomat to streamline construction.

1.1 Project Background: Soft Soil in a High-Density Zone

The task aimed to construct a 12-story rental complicated on a 1.2-hectare web site in central Bangkok. Geotechnical surveys published the soil was once in particular gentle clay, which should now not assist the structure’s weight besides significant reinforcement. Traditional strategies (like pile using alone) would have required 60+ days of soil preparation, risking delays in a market the place well timed transport used to be quintessential for tenant acquisition.

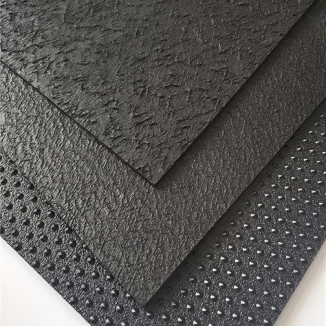

1.2 Geomat Solution: Reinforced Soil Layers for Fast Stabilization

The engineering crew opted to use a non-woven geomat (polyester-based, 300g/m²) paired with granular fill material. The geomat used to be laid in overlapping layers (15cm overlap) throughout the site, appearing as a tensioned membrane to distribute load evenly and forestall soil settlement. Unlike common techniques that require repeated compaction, the geomat’s excessive tensile power allowed the group to omit 2–3 compaction cycles, as the cloth maintained soil integrity on its own.

1.3 Efficiency Impact: 25% Faster Foundation Work

By the use of geomat, the basis education segment was once performed in forty five days—25% shorter than the authentic 60-day estimate. Labor prices additionally dropped by means of 18%, as fewer people have been wished for compaction and soil testing. Post-construction, the basis confirmed zero symptoms of agreement (per 6-month monitoring), proving geomat’s role in each velocity and long-term stability. For city projects, this case demonstrates how geomat turns soft-soil challenges into effectivity wins.

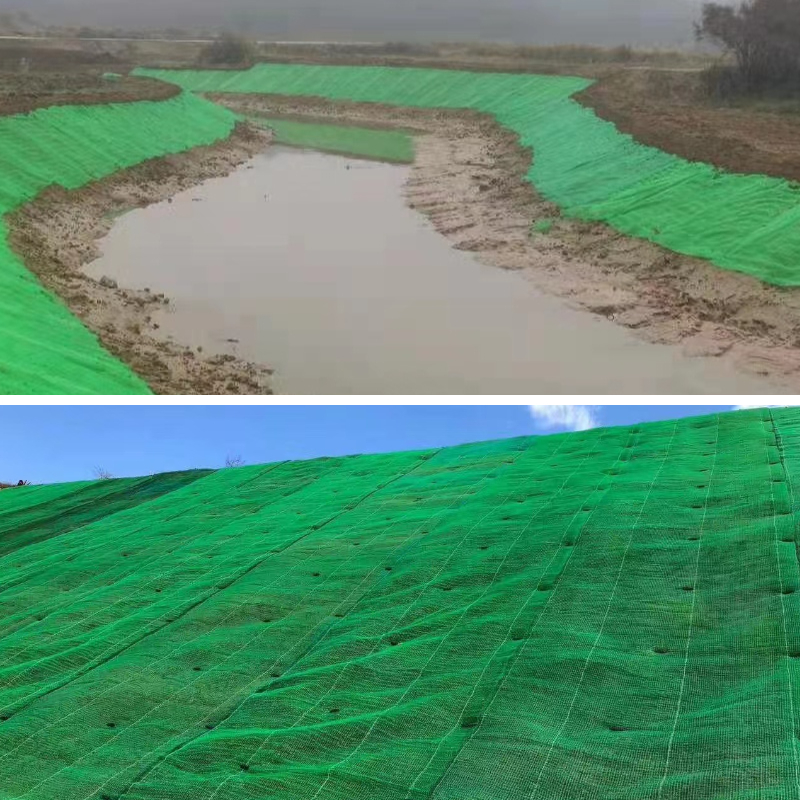

2. Slope Protection: 3D Geomat Reduces Erosion Risks for a Mountain Highway

Slope erosion is a main hazard to street construction, specially in hilly or mountainous areas the place rain and runoff can destabilize terrain. A 2022 motorway growth venture in Sichuan, China, used 3D geomat to defend slopes—and speed up development via addressing erosion proactively.

2.1 Project Background: Erosion Threats to a Mountain Road

The challenge concerned widening a 15km area of dual carriageway connecting Chengdu to Leshan, with slopes ranging from 30° to 50° alongside the route. Historical records confirmed the region obtained 1,200mm of annual rainfall, which had brought about slope screw ups in previous avenue repairs. The group wished a answer that would shield slopes during construction (not simply post-completion) to keep away from weather-related delays.

2.2 3D Geomat Solution: 3D Structure for Dual Protection

Instead of standard concrete conserving partitions (which take 2–3 weeks per 100m of slope), the crew installed 3D geomat—a three-dimensional, porous geosynthetic with a honeycomb structure. The 3D geomat was once anchored to the slope surface, then crammed with neighborhood soil and grass seeds. Its 3D sketch trapped soil particles, avoided runoff, and promoted vegetation growth—all whilst permitting water to drain naturally. Unlike concrete, the 3D geomat used to be light-weight and convenient to install: a crew of 5 may want to cowl 200m of slope per day, in contrast to 50m with concrete.

2.3 Efficiency Impact: 40% Faster Slope Work + Lower Maintenance

The slope safety segment was once completed in 18 days, down from the 30 days deliberate for concrete walls. Additionally, the 3D geomat eradicated the want for post-construction slope repairs (a frequent price with concrete, which cracks over time). Over the first year, the motorway required zero slope-related maintenance—saving the customer an estimated $120,000. This case suggests how 3D geomat combines erosion manipulate with speed, making it best for weather-sensitive projects.

3. Road Construction: Geomat Enhances Subgrade Strength for a Highway Expansion

Highway subgrades (the layer underneath the pavement) should face up to heavy visitors and environmental stress. A 2024 challenge increasing the M6 motorway in the UK used geomat to beef up subgrades, reducing remodel and dashing up pavement laying.

3.1 Project Background: Subgrade Settlement in a High-Traffic Zone

The M6 growth brought two lanes to a 20km stretch, requiring the subgrade to help expanded truck and vehicle visitors (up to 100,000 cars daily). Initial checks observed the subgrade soil had low bearing capacity—without reinforcement, it would settle over time, main to pavement cracks and high priced rework. Traditional options (like changing topsoil with imported gravel) would have introduced three weeks to the timeline and $300,000 in fabric costs.

3.2 Geomat Solution: Woven Geomat for Subgrade Reinforcement

The crew selected a woven polypropylene geomat (with a tensile energy of 80kN/m) to give a boost to the subgrade. The geomat was once laid without delay on the current soil, then included with a 15cm layer of beaten stone. Its woven shape allotted load throughout the subgrade, stopping localized agreement and decreasing the want for high-priced gravel replacement. The geomat additionally acted as a barrier, stopping exceptional soil particles from mixing with the overwhelmed stone— a frequent trouble that weakens subgrades.

3.3 Efficiency Impact: 20% Faster Pavement Laying + No Rework

By the use of geomat, the subgrade coaching took 10 days as a substitute of 14. The pavement layer (asphalt) ought to be laid at once after geomat installation, as the subgrade used to be secure adequate to assist heavy paving equipment. Six months after opening, the new lanes confirmed no signs and symptoms of agreement or cracking—eliminating remodel that would have taken two weeks and $150,000 to fix. For avenue projects, this case proves geomat’s fee in lowering fabric prices and averting highly-priced delays.

4. Ecological Restoration: 3D Geomat Balances Speed and Sustainability for a Riverbank Project

Construction initiatives close to water our bodies frequently face strict environmental regulations, which can sluggish work if options are now not eco-friendly. A 2023 riverbank restoration assignment in Portland, Oregon, used 3D geomat to meet ecological standards and stay on schedule.

4.1 Project Background: Erosion and Environmental Compliance

The mission restored 5km of the Willamette River’s banks, which had eroded due to flooding, threatening close by wetlands and natural world habitats. The U.S. Army Corps of Engineers required the answer to be non-toxic, promote plant growth, and be set up besides disrupting fish spawning seasons (which constrained building to a 8-week window). Traditional rock armoring (riprap) would have met erosion manage desires however failed eco-standards and taken 10 weeks to install—missing the deadline.

4.2 3D Geomat Solution: Eco-Friendly 3D Structure for Restoration

The crew chosen an eco-friendly 3D geomat made from recycled polyester, designed to biodegrade slowly over 5 years (once vegetation used to be established). The 3D geomat used to be rolled alongside the riverbank, secured with biodegradable stakes, and stuffed with native soil and wetland plant seeds. Its 3D honeycomb shape trapped sediment, decreased erosion, and supplied a secure base for vegetation to root—all whilst being protected for fish and wildlife. Installation was once fast: a crew of 6 mounted 1km of 3D geomat per week, twice as quick as riprap.

4.3 Efficiency Impact: On-Time Delivery + Eco-Certification

The challenge was once executed in 7 weeks, beating the 8-week deadline. It additionally earned LEED Gold certification for sustainability, a bonus that helped the patron tightly closed future authorities contracts. Post-project monitoring confirmed a 90% survival price for native plants, and erosion charges dropped with the aid of 85% in contrast to pre-restoration levels. This case highlights how 3D geomat bridges effectivity and ecology—critical for tasks in regulated, touchy areas.

Why Geomat and 3D Geomat Are Game-Changers for Construction Efficiency

Across foundation, slope, road, and ecological projects, geomat and 3D geomat deliver three core effectivity benefits:

Faster Installation: Lightweight, easy-to-handle substances minimize labor time and tools needs.

Reduced Rework: By addressing root reasons (like agreement or erosion), geomat minimizes post-construction fixes.

Cost Savings: Less material, labor, and protection translate to decrease common challenge costs.

For development groups searching to meet deadlines, reduce expenses, and enhance performance, geomat applied sciences are no longer optional—they’re essential. Whether you’re working on a city high-rise or a rural highway, integrating geomat or 3D geomat can flip challenges into possibilities for efficiency.

Ready to analyze how geomat can streamline your subsequent project? Contact our group for customized suggestions tailor-made to your site’s special needs.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province