Benefits of Using HDPE Geomembrane Fabric for Landfill Projects: Why It’s the Top Choice

Landfills are imperative infrastructure for managing strong waste, however they pose substantial environmental dangers if no longer accurate constructed. One of the most imperative elements of a safe, sustainable landfill is the barrier gadget that prevents poisonous leachate from seeping into soil and groundwater. Among the a number substances available, HDPE geomembrane has emerged as the gold standard. This high-density polyethylene fabric provides unmatched overall performance in landfill applications. Below, we discover the key advantages of the usage of HDPE geomembrane material in landfill projects.

1. Superior Impermeability: Protecting Soil and Groundwater

1.1 The Core Role of Impermeable Barriers in Landfills

The predominant cause of any landfill liner gadget is to include leachate— a poisonous liquid fashioned when rainwater mixes with decomposing waste. Without a dependable barrier, leachate can seep into the surrounding soil and groundwater, inflicting long-term environmental infection and fitness hazards.

1.2 Why HDPE Stands Out as an Impermeable Solution

HDPE geomembrane is celebrated for its exquisite impermeability. Unlike clay liners or different artificial materials, HDPE is engineered to have an extraordinarily low permeability rate, regularly as low as 1 x 10^-12 cm/s. This potential it successfully blocks the passage of beverages and gases, even over a long time of use. As an impermeable geomembrane liner, it acts as an impenetrable shield, making sure that leachate stays contained inside the landfill, the place it can be safely accumulated and treated.

1.3 Real-World Impact on Environmental Protection

For example, in municipal strong waste landfills, the place leachate volumes are excessive and chemical composition is complex, an impermeable geomembrane liner made from HDPE prevents unsafe supplies like heavy metals and risky natural compounds (VOCs) from escaping. This safety is indispensable for complying with environmental regulations, such as the EPA’s Resource Conservation and Recovery Act (RCRA) in the U.S., which mandates strict liner requirements for hazardous and non-hazardous waste facilities.

2. Exceptional Durability and Resistance to Environmental Stress

2.1 Chemical Resistance for Long-Term Performance

Landfills are harsh environments. The liner device should face up to excessive temperatures, chemical corrosion from leachate, UV radiation, and bodily stress from waste placement and compaction. HDPE geomembrane is uniquely designed to thrive in these conditions.

HDPE is inherently resistant to a large vary of chemicals, together with acids, alkalis, and solvents in many instances determined in landfill leachate. This chemical resistance prevents the liner from deteriorating or turning into permeable over time.

2.2 UV and Physical Stress Resistance

Additionally, HDPE geomembranes are frequently dealt with with UV stabilizers, making them resistant to degradation from sunlight— a necessary characteristic for the duration of the landfill’s lively phase, when the liner may additionally be uncovered at some point of waste placement.

Physical sturdiness is any other strength. The fabric is challenging adequate to face up to punctures from sharp objects in the waste, such as metallic scraps or damaged glass, and can face up to the weight of heavy equipment used to compact waste. Compared to different liners, which can also crack or degrade underneath stress, geomembrane liner made from HDPE continues its integrity, making sure long-term performance. Most HDPE geomembranes come with a graph lifestyles of 50+ years, making them a dependable preference for long-term landfill projects.

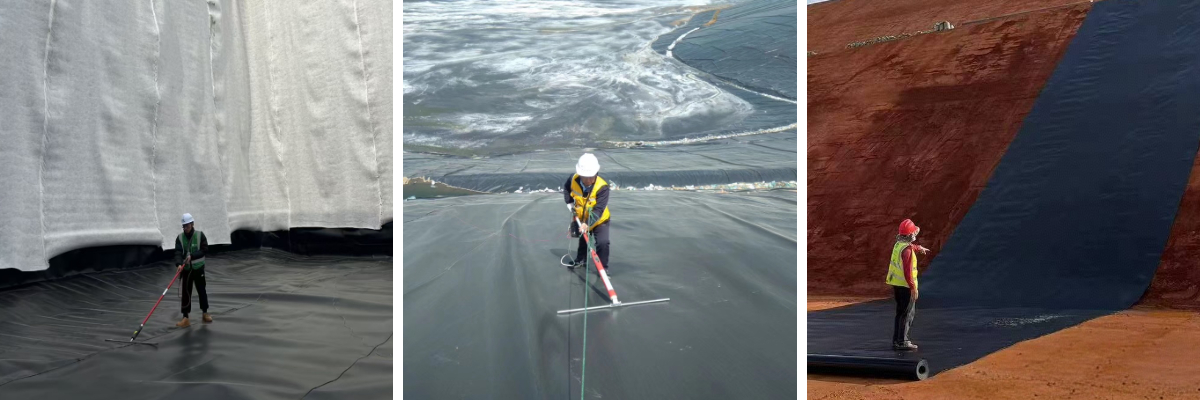

3. Easy Installation and Versatility in Construction

3.1 Efficient Installation Process

Efficiency in development is key to preserving landfill initiatives on agenda and inside budget. HDPE geomembrane stands out for its ease of installation, which reduces labor fees and minimizes task delays.

HDPE sheets are light-weight and flexible, making them handy to transport and take care of on-site. They are normally set up the usage of warmth fusion welding, a procedure that creates strong, seamless joints between sheets. When finished correctly, these welds are as sturdy as the geomembrane itself, putting off susceptible factors the place leaks should occur.

3.2 Adaptability to Various Landfill Designs

The versatility of HDPE geomembrane additionally makes it appropriate for various landfill designs. Whether the landfill is a single-cell facility or a large, multi-phase project, geomembrane liner made from HDPE can be tailored to in shape slopes, trenches, and irregular shapes. It can additionally be blended with different materials, such as geotextiles or clay liners, to create composite barrier structures that decorate performance. This flexibility ensures that HDPE geomembrane works for each new landfills and the rehabilitation of older sites, the place retrofitting with a dependable liner is essential.

4. Cost-Effectiveness Over the Long Term

4.1 Reduced Repair and Replacement Costs

While the preliminary price of HDPE geomembrane can also be greater than some common substances (such as clay), its long-term cost-effectiveness makes it a smarter funding for landfill operators.

First, the sturdiness of HDPE reduces the want for generic repairs or replacements. Clay liners, for example, can crack over time due to contract or drying, requiring luxurious protection to forestall leaks. In contrast, a well-installed HDPE geomembrane hardly ever wants repairs, decreasing long-term operational costs.

4.2 Lower Labor and Liability Costs

Second, the effectivity of set up reduces labor and gear charges for the duration of construction. Faster set up additionally skill the landfill can emerge as operational sooner, producing income faster.

Third, the use of an impermeable geomembrane liner helps landfill operators keep away from fines and cleanup prices related with environmental violations. Leaks from poorly designed liners can lead to groundwater contamination, which may additionally require high-priced remediation efforts and prison penalties. By investing in HDPE geomembrane, operators mitigate these risks, saving money in the lengthy run.

5. Compliance with Regulatory Standards and Environmental Safety

5.1 Meeting Global Regulatory Requirements

Landfill tasks are concern to strict regulatory requirements worldwide, designed to guard public fitness and the environment. HDPE geomembrane is broadly identified and accredited with the aid of regulatory bodies, making sure that landfill operators can meet compliance requirements.

In the U.S., for example, the EPA’s Subtitle D rules for stable waste landfills require liners to meet particular permeability standards, which HDPE geomembrane without difficulty satisfies. Similarly, worldwide requirements (such as these set via the International Organization for Standardization, ISO) understand HDPE as a appropriate fabric for environmental barriers.

5.2 Supporting Sustainable Waste Management

Beyond compliance, HDPE geomembrane helps sustainable landfill practices. By containing leachate and lowering greenhouse gasoline emissions (through its gas-tight properties), it helps landfills function greater responsibly. This aligns with developing public and regulatory needs for environmentally pleasant waste management, bettering the popularity of landfill operators and communities.

6. Low Maintenance and Easy Monitoring

6.1 Simplified Inspection Processes

Maintaining a landfill liner gadget is vital to making sure its performance, and HDPE geomembrane simplifies this process.

The easy floor of HDPE geomembrane makes it handy to investigate for damage. Operators can use visible checks, leak detection structures (such as electrical conductivity tests), or aerial surveys to display the liner’s integrity.

6.2 Quick and Effective Repairs

If a small puncture or tear does manifest (e.g., from unintended harm for the duration of waste placement), it can be rapidly repaired the usage of patch welding, a easy technique that restores the liner’s impermeability.

In contrast, monitoring clay liners or different porous substances is greater challenging, as leaks can take place hidden underneath the surface, making detection and restore difficult. The ease of monitoring and retaining geomembrane liner made from HDPE ensures that any troubles are addressed promptly, stopping small issues from turning into large, high-priced ones.

Conclusion: HDPE Geomembrane is Essential for Modern Landfills

For landfill projects, the desire of liner cloth without delay influences environmental safety, operational efficiency, and long-term cost. HDPE geomembrane excels in all these areas, imparting most desirable impermeability, durability, ease of installation, cost-effectiveness, and compliance with regulations. Whether used as a standalone impermeable geomembrane liner or phase of a composite system, geomembrane liner made from HDPE ensures that landfills function safely and sustainably for decades.

For landfill operators and engineers searching to construct or improve a facility, HDPE geomembrane is the clear choice— defending the environment, decreasing risks, and imparting long-term value.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province