5 Common Geomembrane Installation Mistakes and How to Avoid Them

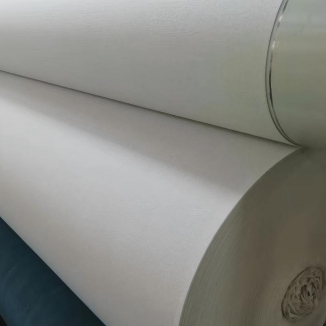

A profitable geomembrane set up is the cornerstone of any high quality containment system. Whether for landfills, water reservoirs, or mining operations, the integrity of this geomembrane waterproofing layer is paramount. However, even the most meticulously designed mission can be compromised via mistakes throughout the set up phase. These errors can lead to leaks, environmental damage, high-priced repairs, and mission failures.

Understanding these frequent pitfalls is the first step towards prevention. This information will stroll you thru 5 of the most widely wide-spread geomembrane set up mistakes and furnish actionable recommendation on how to keep away from them, making sure your liner performs as meant for a long time to come.

1. Inadequate Subgrade Preparation

The basis of any long lasting geomembrane waterproofing device is a accurate organized subgrade. The subgrade is the soil or floor upon which the geomembrane is laid. Rushing this crucial first step is a recipe for disaster.

The Mistake:

Installing the geomembrane on a subgrade that includes sharp rocks, debris, uneven surfaces, or uncompacted soil. This can lead to punctures, stress concentrations, and uneven settling, which over time, can rupture the liner.

How to Avoid It:

●Thorough Inspection and Clearing: Before any geomembrane is unrolled, the subgrade ought to be meticulously cleared of all vegetation, roots, stones, and any different protruding objects.

●Proper Compaction: The soil should be uniformly compacted to the distinct density to stop future settlement. Use terrific compaction tools and behavior exams to make certain consistency.

●Smooth Surface: The aim is a smooth, uniform floor free of voids, cracks, and sharp transitions. Any required fine-grading must be finished with non-abrasive tools.

●Verification: Never proceed with the geomembrane set up till the subgrade has been formally inspected and permitted via a certified engineer or web site supervisor.

2. Improper Seaming and Welding Techniques

The seams are the weakest factors in any geomembrane system. Faulty seaming is arguably the main purpose of geomembrane failure, making ideal HDPE geomembrane welding and scanning honestly critical.

The Mistake:

This encompasses a vary of errors, which includes fallacious temperature/pressure settings for HDPE geomembrane welding, dirty or moist seam interfaces, insufficient overlap, and a lack of certified personnel and high-quality control.

How to Avoid It:

●Certified Welders: Ensure that all HDPE geomembrane welding is carried out via licensed and skilled technicians who recognize the unique fabric and environmental conditions.

●Test Seams: Before beginning manufacturing seaming, function check seams on a every day basis. These take a look at strips are then destructively examined in a lab to verify the weld parameters are right for that day's weather.

●Clean and Dry Surfaces: The seam vicinity need to be flawlessly clean, dry, and free of condensation, dust, or particles right away earlier than welding. Have cleansing resources and air blowers on hand.

●Continuous Monitoring: Use a dual-track fantastic manipulate system. First, habits non-destructive checks (like air stress checking out on dual-track seams) on one hundred percent of the seams. Second, function detrimental shear and peel exams on samples reduce from discipline seams at normal intervals.

3. Poor Handling and Placement of the Geomembrane Panels

The geomembrane sheets are vulnerable all through coping with and placement. Carelessness at some stage in this section can introduce harm that goes neglected till it is too late.

The Mistake:

Dragging geomembrane panels throughout the hard subgrade, the usage of inappropriate lifting techniques, or taking walks on the liner with soiled or sharp-footed sneakers can purpose scratches, cuts, and punctures that compromise the geomembrane waterproofing integrity.

How to Avoid It:

●Lift, Don't Drag: Always use wide, gentle slings or different permitted strategies to raise and region geomembrane rolls and panels. Never drag them over the ground.

●Controlled Unrolling: Unroll the panels cautiously and systematically, making sure they are laid flat barring immoderate wrinkles however additionally barring being stretched.

●Staging Areas: Use brief bedding layers or existing, easy areas for staging rolls earlier than closing placement to reduce contact with abrasive surfaces.

●Strict Site Protocols: Enforce a "clean shoe" coverage for every person strolling on the hooked up geomembrane. Require soft-soled, easy boots and preclude get admission to to imperative personnel only.

4. Inadequate Protection Layers

An mounted geomembrane is frequently included through different materials, such as drainage gravel or soil. Without a acceptable protecting barrier, these overlying substances can motive extensive damage.

The Mistake:

Placing sharp, heavy drainage combination or cowl soil at once onto the geomembrane liner. The stress and sharp edges can puncture or stress the material, negating all the cautious work of the geomembrane installation.

How to Avoid It:

●Use a Geotextile Cushion: The most frequent and nice answer is to deploy a non-woven geotextile as a shielding cushioning layer on pinnacle of the geomembrane. This layer absorbs punctures and distributes masses from the overlying materials.

●Controlled Placement of Cover Material: When putting cover soil or aggregate, do so from a low height. Avoid dumping massive portions from a awesome height, which can purpose influence damage. Use tracked tools with low floor strain and make certain it constantly operates on a adequate thickness of cowl fabric to keep away from direct contact with the geomembrane.

5. Neglecting Environmental and On-Site Conditions

The climate and instant job website online surroundings play a big position in the success of a geomembrane waterproofing project. Ignoring these elements can lead to irreversible damage.

The Mistake:

Attempting geomembrane set up throughout excessive winds, rain, or intense temperatures. Wind can whip and tear the sheets, whilst moisture prevents suitable HDPE geomembrane welding. Heat can motive immoderate expansion, and bloodless can make the cloth brittle.

How to Avoid It:

●Monitor Weather Forecasts: Have a clear climate plan. Postpone HDPE geomembrane welding and panel placement all through rain, snow, or when wind speeds exceed secure limits.

●Manage Temperature Effects: In hot, sunny weather, be conscious of thermal expansion. Allow the geomembrane to loosen up and acclimate, and make seams when the fabric is in a extra impartial state, such as early morning or evening. Avoid coping with in very bloodless prerequisites the place the cloth turns into stiff and inclined to cracking.

●Secure Unanchored Liners: Never depart giant areas of uncovered geomembrane unanchored in a single day or for the duration of windy periods. Use sandbags or different authorised ballasts to impervious the sheets firmly in place.

Conclusion: Quality Assurance is Key

A profitable geomembrane set up is no longer simply about keeping off these 5 mistakes; it is about imposing a sturdy Quality Assurance/Quality Control (QA/QC) application from begin to finish. This includes educated crews, meticulous documentation, and consistent vigilance. By prioritizing desirable subgrade preparation, getting to know HDPE geomembrane welding techniques, managing substances with care, the usage of protecting layers, and respecting environmental conditions, you can make sure your geomembrane waterproofing device offers a reliable, long-lasting seal. Investing time and sources in right set up practices is the most budget friendly strategy, saving you from the large fee and legal responsibility of a containment failure down the line.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province