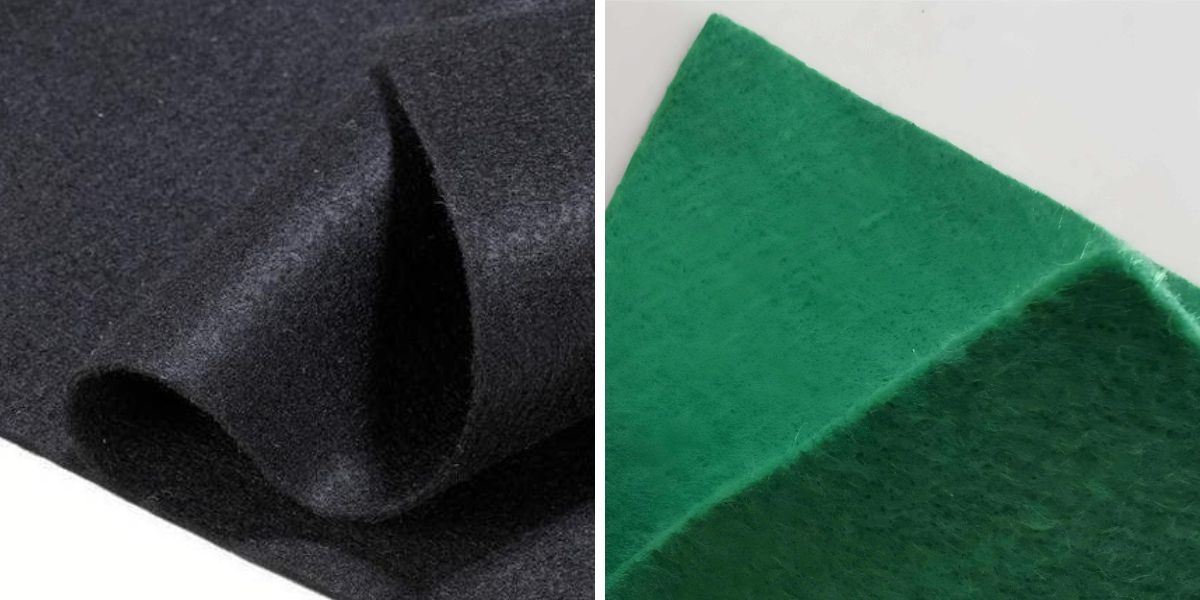

Geotextile 180g

1.Excellent anti-seepage and barrier effect:Water blocking, liquid blocking, leakage prevention, water and soil protection, and pollution prevention.

2.Strong protection enhancement capability:Disperse loads to resist erosion, stabilize structures and reduce damage.

3.Good drainage and breathability performance:Porous rapid drainage of accumulated water, reducing pressure to ensure dryness.

4.Durable construction with low cost:It is light, easy to lay, material saving, corrosion and aging resistant, long service life and low cost.

Product Introduction

Basic attributes

Geotextile 180g are made from polymer materials such as polypropylene and polyester fibers as the core raw materials, processed through weaving, needle punching, hot rolling, or spunbonding processes to form sheet-like materials with a certain thickness and pore structure. Its physical characteristics are characterized by a gentle texture and excellent flexibility, moderate weight per roll, and the ability to fold and cut flexibly according to engineering needs, making transportation and construction operations convenient; In terms of chemical properties, it has excellent resistance to acid and alkali corrosion, can resist the erosion of chemical substances in soil, industrial waste liquid, etc., and has strong anti-aging and ultraviolet resistance. Even in the complex and harsh environment of high temperature exposure, cold frost, damp and rainy, it can still maintain structural integrity and stable mechanical properties for a long time.

Core functions

Anti leakage barrier: By relying on the dense fiber structure or composite anti leakage coating of the material itself, an effective physical barrier can be constructed to accurately block the infiltration of liquids such as surface water, groundwater, industrial wastewater, and leachate from garbage, while also blocking the diffusion of harmful gases such as methane. In water conservancy dams, artificial lakes, landfill sites and other projects, effective measures are taken to prevent structural instability caused by leakage, and to avoid pollution of surrounding soil and water resources by pollutants.

Protection enhancement: Through the buffering and stress dispersion effect of the fiber layer, external forces such as vehicle loads and water flow impact are evenly transmitted to the base soil, reducing local pressure concentration. In road engineering, it can protect the roadbed from rolling damage, and in river regulation and slope protection projects, it can resist the erosion of embankments and slopes by water flow, significantly reducing the risk of structural settlement, cracking, collapse and other diseases, and stabilizing the soil and roadbed foundation.

Drainage and Breathability: Utilizing the criss crossing fiber gaps inside the material to form natural drainage channels, it has good permeability and breathability. In civil engineering construction, it is possible to quickly discharge excess accumulated water in the soil due to rainfall and groundwater infiltration, timely reduce the pore water pressure of the soil, avoid problems such as soil softening and reduced bearing capacity caused by water accumulation, and ensure that engineering structures such as roads, foundation pits, and landfills are in a dry and stable state.

Main features

Convenient construction: The product is lightweight and easy to transport, with high laying efficiency after single roll unfolding, and does not require the assistance of large lifting equipment. The laying operation can be completed manually. The material cutting has high flexibility and can accurately adapt to the size requirements of different projects, greatly reducing the waste of corner materials. Compared to traditional anti-seepage and protective materials, it can shorten the construction period by more than 30% and significantly reduce the investment in labor, equipment, and materials costs.

Strong durability: High strength polymer materials and advanced production technology are used, with outstanding corrosion resistance and aging resistance. It can withstand soil microbial erosion, chemical corrosion, ultraviolet radiation, cold and hot alternation and other natural environmental effects for a long time. Under normal usage conditions, the service life can reach 20-50 years, effectively extending the overall service life of the project and reducing maintenance costs such as later repairs and replacements.

Product Parameters

| project | metric | ||||||||||

| Nominal strength/(kN/m) | |||||||||||

| 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

| 1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

| 2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

| 3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

| 4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

| 5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

| 6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

| 7 | Width deviation rate /% ≥ | -0.5 | |||||||||

| 8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

| 9 | Thickness deviation rate /% ≥ | -10 | |||||||||

| 10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

| 11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

| 12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

| 13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

| 14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

Application in Water Conservancy Engineering

In hydraulic engineering, geotextile is an indispensable key material. In dam construction, it is laid inside and on the surface of the dam body, with excellent anti-seepage performance to prevent dam leakage. At the same time, it resists the erosion of the dam slope by water flow through protective effect, reduces soil erosion, and ensures the long-term stability of the dam structure. In channel engineering, laying geotextile can prevent the collapse of channel slopes, reduce the impact of water flow infiltration on surrounding soil, and improve the water delivery efficiency of channels. The anti-seepage treatment of artificial lakes, reservoirs and other water conservancy facilities often relies on geotextiles, which can effectively reduce water leakage and save water resources.

Application in Road Construction

Geotextiles are widely used in the field of road construction to improve engineering quality. In the roadbed treatment stage, laying geotextile between the roadbed soil and the cushion layer can play an isolation role, prevent soil of different particle sizes from mixing with each other, disperse vehicle loads, reduce roadbed settlement and deformation, and avoid problems such as cracking and collapse of the road surface. Laying geotextile between the base and surface layers of the road can enhance the overall integrity and fatigue resistance of the road surface, and extend the service life of the road. For soft soil foundation sections, geotextiles can also be combined with other materials to form composite foundations, improve the bearing capacity of the foundation, and ensure the safety of road construction and use.

Application in Environmental Protection Engineering

In environmental engineering, the anti-seepage and protective functions of geotextiles are fully utilized. In the construction of landfill sites, geotextiles serve as the core component of the anti-seepage system, laid at the bottom and surrounding areas of the landfill area, effectively blocking the infiltration of leachate into underground soil and water bodies, and preventing environmental pollution. In sewage treatment plants, geotextiles are used for anti-seepage and filtration of sedimentation tanks, filtration tanks, and other facilities to ensure the stability of the sewage treatment process and avoid environmental pollution caused by sewage leakage. In addition, geotextiles can prevent tailings slurry leakage and protect the surrounding ecological environment in tailings treatment projects.

Application in Municipal and Civil Engineering

In municipal and civil engineering, geotextiles have diverse application scenarios. When laying underground pipelines, laying geotextile around the pipeline can reduce the pressure and friction of soil on the pipeline, protect the pipeline from damage, and also serve as drainage to prevent corrosion caused by water accumulation around the pipeline. In foundation pit support engineering, geotextile can be combined with other support materials to play a role in drainage and slope reinforcement, reduce the risk of foundation pit collapse, and ensure construction safety. In landscaping projects, geotextiles are used for drainage and isolation in artificial wetlands, roof greening, and other projects to improve the plant growth environment and enhance the greening effect.

Geotextile, with its excellent functions of anti-seepage, protection, drainage, etc., has a wide and important application in many engineering fields such as water conservancy, roads, environmental protection, and municipal engineering. It can not only improve the stability and safety of engineering structures, reduce the occurrence of engineering diseases, but also play a role in protecting the ecological environment and saving resources. At the same time, the convenient and durable characteristics of geotextile construction reduce the overall cost of the project, providing strong guarantees for the smooth implementation and long-term operation of various projects, and becoming an indispensable key material in modern engineering construction.