What is a Geomembrane? A Beginner's Guide to Impermeable Liners

In our modern world, managing liquids and gases is a essential project at some point of severa industries. From making positive our eating water is convenient to safely containing waste, the choose for reliable boundaries is paramount. This is the location the geomembrane comes into play. If you have ever puzzled what these supplies are and how they shield our environment and infrastructure, you have bought come to the desirable place. This data will damage down the complete lot a newbie wishes to understand about these necessary engineering liners.

What Exactly is a Geomembrane?

Let's start with the basics. A geomembrane is a synthetic, impermeable membrane liner or barrier. These sheets have an incredibly low permeability, that ability they are designed to manipulate the movement of fluids (liquids or gases) in a human-made project, structure, or system.

Think of a geomembrane as a giant, tremendously lengthy lasting tarp. But now not like a handy tarp, it is engineered to be impenetrable to chemicals, resistant to punctures and tears, and succesful to face up to immoderate environmental stipulations for decades. They are manufactured from instead skinny continuous polymeric sheets, which are then deployed on-site to create a contained area. The integral attribute of any geomembrane is generally containment and isolation.

The Different Types of Geomembranes

Not all geomembranes are created equal. They are manufactured from wonderful sorts of polymers, each presenting unique houses perfect for special applications. The choice of fabric depends upon on factors like chemical resistance, flexibility, durability, and cost. Here are some commonplace types:

HDPE (High-Density Polyethylene): This is one of the most extensively used types. HDPE geomembrana is renowned for its immoderate chemical resistance, durability, and fairly low cost. It is stiff and has a immoderate resistance to ultraviolet (UV) light, making it best for uncovered functions like landfills and reservoir liners.

LLDPE (Linear Low-Density Polyethylene): More flexible than HDPE, LLDPE geomembranes can conform to uneven subgrades greater and are greater resistant to stress cracking.

PVC (Polyvinyl Chloride): Highly flexible and handy to install, PVC geomembranes are regularly used in functions like canal lining and wastewater ponds.

EPDM (Ethylene Propylene Diene Monomer): Known for its fantastic local weather resistance and flexibility, EPDM is usually used in pond and lagoon liners.

PP (Polypropylene): Similar to HDPE alternatively with greater stress crack resistance, it is normally used in uncovered functions requiring a textured ground for slope stability.

When deciding on a material, it is necessary to are seeking recommendation from with a skilled geomembrane manufacturer to make sure the product meets the unique technical requirements of your project.

How Are Geomembranes Made? The Manufacturing Process

The machine of developing a geomembrane is a modern-day one, commonly involving extrusion methods. Here’s a simplified breakdown:

1.Raw Material Preparation: The predominant polymer resin (e.g., polyethylene pellets) is blended with aspects such as carbon black (for UV resistance), plasticizers (for flexibility), antioxidants, and stabilizers.

2.Extrusion: The blended cloth is fed into an extruder. Here, it is heated until molten and then compelled through a flat die to form a continuous flat sheet. For HDPE geomembrana, this often creates a effortless surface.

3.Calendering and Cooling: The hot, molten sheet is then surpassed by way of a series of rollers (calenders) that precisely manipulate its thickness and width. It is as a end result cooled to solidify it into its final sheet form.

4.Texturing (Optional): For some applications, in unique steep slopes, a textured floor is brought to lengthen friction and stability. This can be accomplished by co-extruding a textured layer or by using the use of making use of a texture after the essential sheet is formed.

5.Quality Control and Rolling: The completed geomembrane is cautiously examined for thickness, uniformity, and integrity. Once it passes inspection, it is rolled onto huge cores for handy transportation to the undertaking site.

A decent geomembrane manufacturer will have strict great assurance protocols at some factor of this method to make certain the closing product meets all required world necessities.

Key Applications: Where Are Geomembranes Used?

The versatility of geomembranes makes them fundamental in a considerable array of industries. Their core attribute is commonly to furnish a reliable barrier.

Environmental Protection: This is one of the best software program areas. They are used to line landfills, stopping toxic leachate from contaminating groundwater. They moreover cap landfills to encompass gases and end rainwater ingress.

Water Management:HDPE geomembrana is frequently used to line potable water reservoirs, irrigation canals, and emergency spillways. This prevents water loss by using seepage and protects the water from exterior contamination.

Mining and Energy: In mining, geomembranes line heap leach pads and tailings ponds, containing chemical picks and waste byproducts. They are moreover necessary in brine ponds for image voltaic salt manufacturing and for lining firewater retention ponds at strength facilities.

Agriculture: From lining aquaculture ponds for fish farming to developing impermeable bases for manure storage, geomembranes aid the agricultural business enterprise feature efficaciously and responsibly.

Civil Engineering: They are used as waterproofing liners internal tunnels, beneath highways to give up soil sickness from de-icing salts, and in foundation boundaries for buildings.

The Importance of Proper Installation

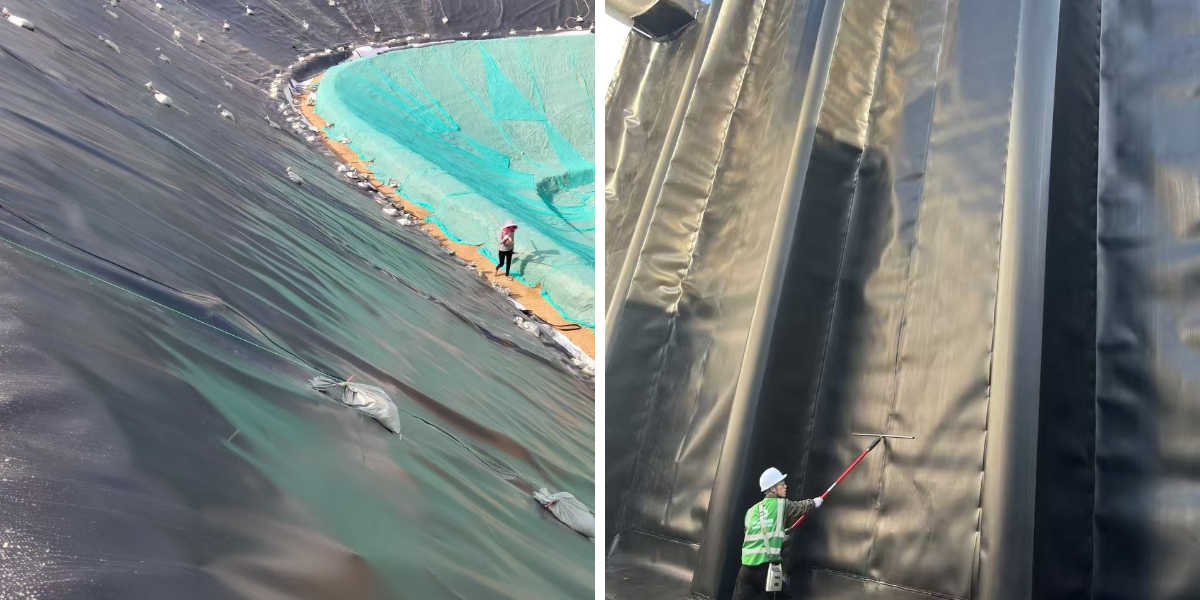

Even the absolute excellent excellent geomembrane can fail if now no longer set up correctly. Installation is a specialised technique that usually involves:

1. Subgrade Preparation: The ground want to be smoothed and compacted to put off any sharp rocks or particles that may additionally favor to puncture the liner.

2. Panel Deployment: Rolls of geomembrane are unrolled and positioned during the geared up area.

3. Panel Scanning: Adjacent panels are fused together the utilization of thermal welding (for HDPE, LLDPE) or chemical welding (for PVC) to create a continuous, impermeable seal. This is a critical step that requires professional technicians.

4. Testing and Inspection: Every seam is non-destructively examined (e.g., with air pressure or vacuum tests) to make sure it is flawlessly sealed.

5. Backfilling: Once the liner computer is approved, it is cautiously blanketed with a defending layer of soil or specific material.

It is mainly inspired to work with an expert installer, oftentimes advocated through the use of your geomembrane manufacturer, to guarantee a worthwhile installation.

Conclusion: The Unsung Hero of Modern Infrastructure

The geomembrane may additionally moreover no longer be a glamorous product, alternatively it is an unsung hero of ultra-modern engineering. It performs a silent however quintessential role in defending our environment, conserving our water resources, and enabling industrial and agricultural techniques to attribute safely. Whether it is a huge HDPE geomembrana lining a ingesting water reservoir or a flexible liner in a outside pond, these impermeable boundaries are indispensable to a sustainable and healthy world. When embarking on a project that requires containment, partnering with a relied on geomembrane manufacturer is the first step in the direction of making certain its long-term success and integrity.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province