Using Geomembranes in Wastewater Treatment Plants: A Sustainable Solution

In the global push for environmental sustainability, wastewater remedy plant life play a fundamental function in defending water sources and public health. As these offerings try to meet stricter suggestions and minimize their ecological footprint, innovative picks like geomembranes have emerged as game-changers. A geomembrane is a synthetic membrane material designed to manipulate fluid migration, making it an best want for a vary of functions internal wastewater treatment processes. This article explores how geomembranes, particularly HDPE membranes, are transforming wastewater treatment flora into more efficient, cost-effective, and sustainable operations.

The Role of Geomembranes in Modern Wastewater Treatment

Wastewater remedy plant life cope with difficult processes, from vital sedimentation to most beneficial filtration, and each stage requires sturdy containment constructions to give up leaks and contamination. Traditional elements like concrete or clay liners regularly fall short due to immoderate safety costs, susceptibility to cracks, and restricted flexibility. This is the region geomembranes step in.

A geomembrane liner acts as a barrier that stops the seepage of wastewater, sludge, or chemical materials into the surrounding soil and groundwater. By developing an impermeable layer, geomembranes shield natural water sources from pollutants, making positive compliance with environmental standards. In essential remedy areas such as clarifiers and equalization tanks, geomembrane liners cease the get away of raw or partly dealt with wastewater, reducing the hazard of soil and water pollution.

Moreover, geomembranes make a contribution to the sustainability of wastewater remedy vegetation with the aid of way of extending the lifespan of infrastructure. Unlike concrete, which can degrade over time due to chemical publicity and temperature fluctuations, geomembranes are resistant to corrosion and wear, minimizing the choose for usually going on repairs. This sturdiness no longer fully lowers long-term operational prices on the other hand moreover reduces the environmental affect associated with material choice and construction.

Why HDPE Membrane Stands Out in Wastewater Applications

Among the a wide variety types of geomembranes available, HDPE membrane (high-density polyethylene) has flip out to be the favored desire for wastewater treatment plants. Its extraordinary residences make it well-suited for the harsh conditions of these facilities, the vicinity publicity to chemicals, immoderate temperatures, and consistent moisture is common.

HDPE membrane is exceedingly resistant to chemical corrosion, making it best for lining tanks and lagoons that keep wastewater, sludge, or dealt with effluents. Unlike distinct materials, it does no longer degrade when in contact with acids, alkalis, or herbal compounds, making certain long-term general overall performance and reliability. Additionally, its smooth ground prevents the buildup of solids and bacteria, reducing the choose for general cleaning and maintenance.

Another key advantage of HDPE membrane is its flexibility and durability. It can face up to extreme temperature fluctuations barring cracking or shrinking, making it gorgeous for use in every heat and cold climates. Its immoderate tensile electrical energy moreover lets in it to face up to punctures and tears, even in high-traffic areas of the remedy plant. This resilience interprets to a longer provider life, often exceeding 30 years, which reduces the favor for replacement and lowers the everyday environmental impact.

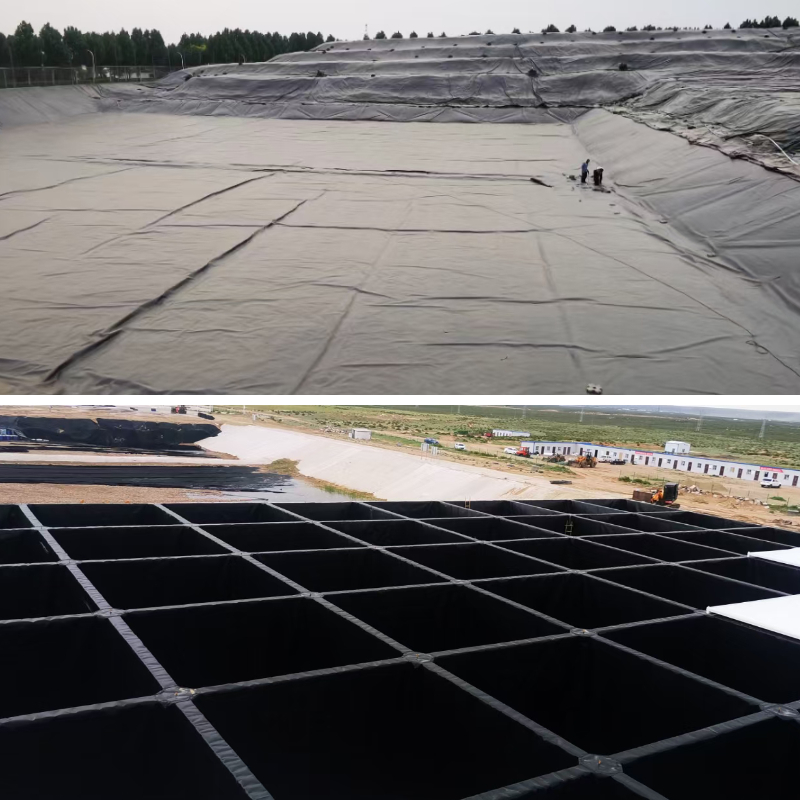

Applications of Geomembrane Liner in Wastewater Treatment Plants

Geomembrane liner is used in a good sized differ of functions internal wastewater remedy plants, each and every contributing to multiplied effectivity and sustainability. One of the most widely wide-spread makes use of is in the lining of anaerobic digesters, the area herbal be counted is broken down to produce biogas. The geomembrane liner prevents the leakage of methane and one of a kind gases, making certain impenetrable and surroundings pleasant biogas sequence at the same time as defending the surrounding environment from contamination.

In secondary treatment processes, geomembrane liners are used to line aeration basins and clarifiers. These areas require a dependable barrier to consist of activated sludge and dealt with water, and geomembranes provide the crucial impermeability to stop seepage. By maintaining the integrity of these systems, geomembrane liners aid optimize the remedy process, making certain that air pollution are correctly eradicated formerly than the water is discharged or reused.

Geomembrane liners are moreover necessary in the constructing of sludge storage lagoons. Sludge, a byproduct of wastewater treatment, consists of immoderate tiers of herbal be counted and pathogens, making ideal containment critical. A geomembrane liner prevents sludge from leaching into the soil and groundwater, lowering the hazard of environmental contamination and making positive compliance with regulatory requirements. Additionally, the effortless ground of the geomembrane liner makes it less complicated to dewater and dispose of sludge, improving operational efficiency.

Environmental and Economic Benefits of Using Geomembranes

The adoption of geomembranes in wastewater treatment plant life gives every environmental and monetary benefits, making them a sustainable want for present day facilities. From an environmental perspective, geomembranes play a critical feature in defending water property and reducing pollution. By stopping leaks and seepage, they decrease the risk of groundwater contamination, holding aquatic ecosystems and making positive get proper of entry to to convenient water for communities.

Geomembranes moreover help the spherical financial machine thru facilitating the reuse of dealt with wastewater. Many remedy vegetation now recycle dealt with water for irrigation, industrial processes, or even eating water, and geomembrane liners make certain that this water stays free from contaminants in the path of storage and distribution. This reduces reliance on freshwater sources, conserving water for one-of-a-kind makes use of and merchandising sustainable water management.

Economically, geomembranes provide huge charge monetary financial savings in distinction to everyday liners. Their handy set up approach reduces improvement time and labor costs, while their prolonged issuer existence minimizes the favor for repairs and replacements. Additionally, the reduced safety requirements of geomembrane buildings limit operational prices over time. For example, HDPE membrane liners in lagoons require a great deal much less frequent cleaning than concrete liners, saving every time and resources.

Furthermore, the use of geomembranes can help wastewater remedy plants maintain away from excessive priced fines and penalties for non-compliance with environmental regulations. By making certain great containment and stopping pollution, these facilities can hold their going for walks licenses and shield their recognition internal the community.

Installation and Maintenance Best Practices for Geomembranes

To maximize the universal overall performance and sturdiness of geomembranes in wastewater remedy plants, perfect set up and renovation are essential. During installation, the net website ought to be cautiously prepared to make positive a smooth, tightly closed flooring free from rocks, roots, and exclusive sharp objects that may additionally favor to puncture the geomembrane. The geomembrane liner want to be set up through way of skilled professionals the use of specialised equipment to make positive applicable sealing and welding, as even small gaps can lead to leaks.

Welding is a vital step in geomembrane installation, on the whole for HDPE membrane. Heat fusion welding creates a strong, continuous bond between panels, making certain the liner’s impermeability. After installation, rigorous testing, such as vacuum checking out or stress testing, should be carried out to find out any defects and make positive the liner meets first-rate standards.

Regular safety is moreover key to extending the life of a geomembrane system. This consists of occasions inspections to take a appear at for signs and symptoms and signs and symptoms of damage, such as tears, punctures, or UV degradation. Any repairs have to be made right away the utilization of like minded resources to maintain the liner’s integrity. Additionally, maintaining the ground of the geomembrane easy and free from particles helps cease harm and ensures perfect performance.

The Future of Geomembranes in Sustainable Wastewater Management

As wastewater remedy plant life proceed to evolve to meet the wants of a creating populace and stricter environmental regulations, geomembranes are poised to play an even giant function in sustainable management. Advances in material science are fundamental to the enchancment of increased lengthy lasting and environmentally fine geomembranes, such as these made from recycled resources or designed to be biodegradable at the give up of their provider life.

Innovations in set up techniques, such as robotic welding, are moreover bettering the effectivity and reliability of geomembrane systems, decreasing the risk of human error and making positive constant quality. Additionally, the integration of geomembranes with wise monitoring systems, which use sensors to find out leaks and tune universal overall performance in real-time, is bettering the functionality of plant operators to manipulate their offerings proactively.

By combining these tendencies with the tested benefits of geomembranes—such as their durability, cost-effectiveness, and environmental performance—wastewater treatment vegetation can proceed to decorate their operations, restrict their ecological footprint, and make a contribution to a greater sustainable future.

In conclusion, the use of geomembranes, particularly HDPE membrane, in wastewater treatment vegetation offers a sustainable reply to the challenges of containment, air air pollution prevention, and operational efficiency. By offering a reliable barrier in the direction of leaks, reducing protection costs, and defending natural resources, geomembranes are helping these offerings meet their environmental needs while making certain the health and safety of communities. As technological knowledge continues to advance, geomembranes will barring doubt remain a cornerstone of sustainable wastewater administration for years to come.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province