Understanding 3D Vegetation Net Specifications: Material and Durability Factors

Introduction: Why 3D Vegetation Net Specifications Matter for Erosion Control

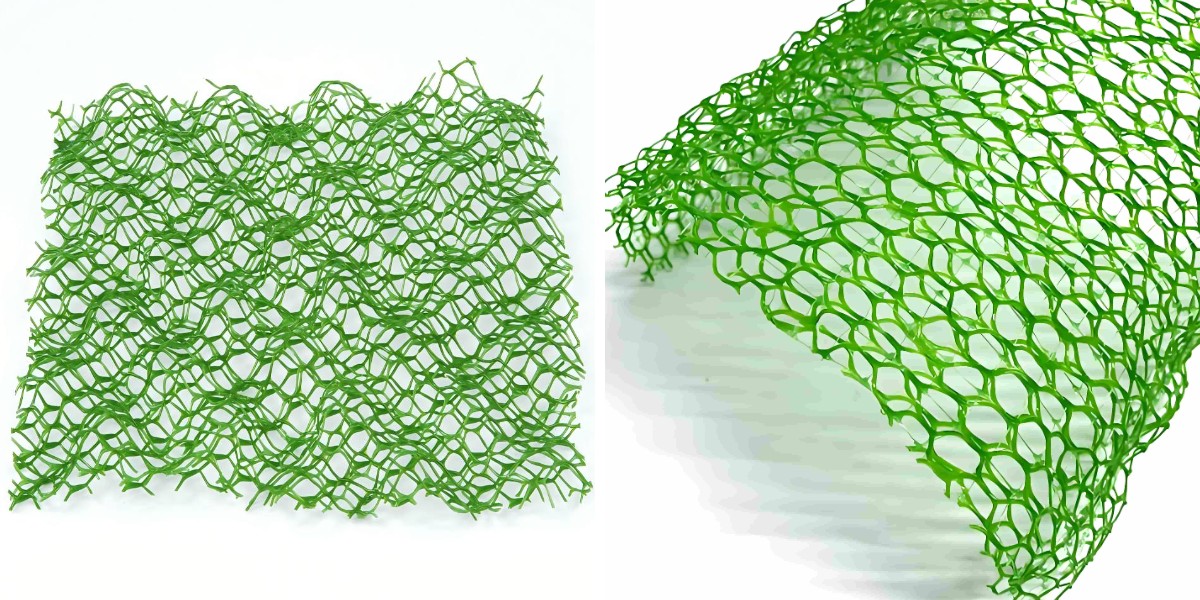

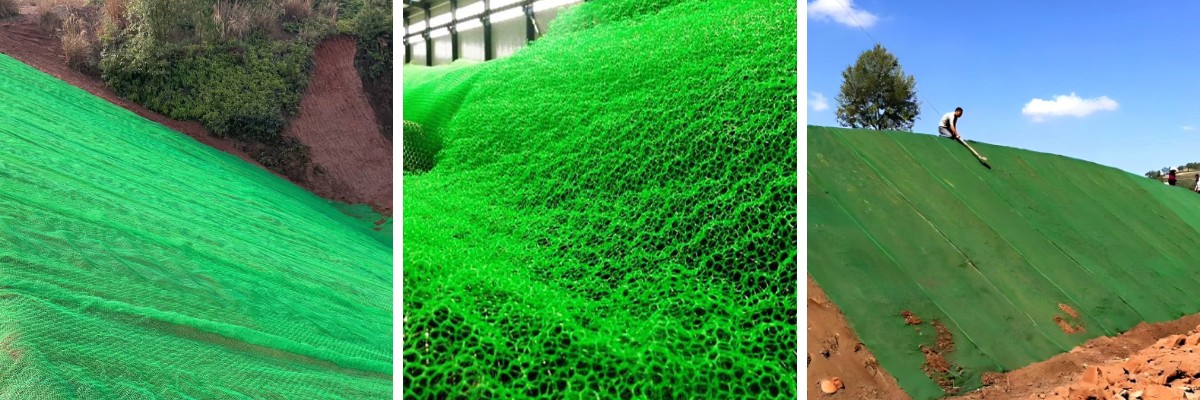

In the realm of soil stabilization and erosion prevention, 3D vegetation nets(https://www.cggeosynthetics.com/geomat-slope/3d-vegetation-net.htmlhttps://www.cggeosynthetics.com/geomat-slope/3d-vegetation-net.html) have emerged as a game-changing solution. Unlike standard flat nets, their three-dimensional structure creates a sturdy matrix that anchors soil, promotes vegetation growth, and withstands environmental stressors. But to leverage their full potential, grasp 3D vegetation net specifications—especially material composition and durability factors—is critical.Whether you’re a contractor planning to Lay 3D vegetation internet on a steep slope or an engineer evaluating alternatives to erosion control geomat, understanding what makes these nets extraordinary ensures long-term project success.

Key Materials in 3D Vegetation Nets: What Defines Their Performance?

The effectiveness of a 3D vegetation net starts offevolved with its material. Manufacturers prioritize polymers known for strength, flexibility, and compatibility with plant growth. Here are the primary materials used:

1. Polypropylene (PP)

Polypropylene is the most common material in 3D vegetation nets. It affords excellent tensile strength, resistance to chemical degradation, and affordability. PP nets are lightweight, making them easy to deal with when you Lay 3D vegetation net across massive areas. Their porous structure allows water and vitamins to reach soil, supporting seed germination—a key benefit over rigid alternatives.

2. Polyester (PET)

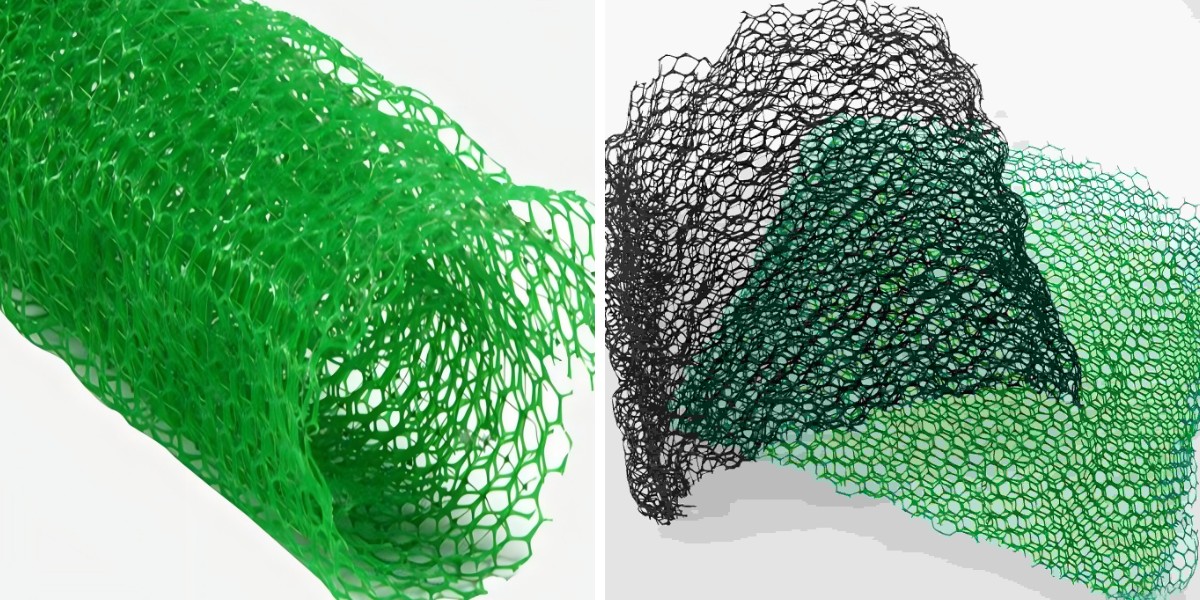

Polyester nets are valued for their superior durability, particularly in high-stress environments. PET has higher UV resistance than PP, making it ideal for sunny, uncovered slopes where prolonged daylight can break down weaker materials. While slightly heavier, polyester 3D vegetation nets excel in tasks requiring long-term stability, such as permanent slope protection.

3. Co-Extruded Blends

Some 3D vegetation nets combine PP and PET in a co-extruded design, merging the high-quality of both: PP's flexibility and PET's UV resistance. These blends are often chosen for versatile applications, from riverbank stabilization to highway embankments, the place the net must adapt to various soil types and weather conditions.

Each fabric impacts how the net interacts with its environment. For example, PP nets are a in your price range choice for temporary projects, whilst PET-based options are better suitable for permanent installations alongside Geomat for Slope Protection systems.

Durability Factors: How 3D Vegetation Nets Withstand the Elements

A 3D vegetation net's lifespan depends on its capacity to resist wear from weather, water, and bodily stress. Here are the critical durability elements outlined in 3D vegetation net specifications:

1. UV Resistance

Prolonged exposure to daylight degrades most polymers over time, weakening the net’s structure. High-quality 3D vegetation nets include UV stabilizers in their material blend. Specifications regularly cite “UV resistance rating,” measured by hours of sunlight publicity before significant tensile power loss. For example, a net rated for 5,000+ hours of UV exposure is perfect for arid, sunny regions—far outperforming standard erosion control geomat in such conditions.

2. Tensile Strength

Tensile energy (measured in kN/m) indicates how much pressure the net can withstand earlier than tearing. This is crucial when Lay 3D vegetation net on slopes inclined to landslides or heavy rainfall. Most 3D nets range from 10-30 kN/m in tensile strength, with polyester blends topping the scale. This ensures the net stays intact even when soil shifts or vegetation roots exert pressure.

3. Water and Chemical Resistance

3D vegetation nets ought to resist hydrolysis (breakdown from water) and chemical exposure from fertilizers, pesticides, or industrial runoff. PP and PET are inherently water-resistant, however premium nets undergo additional treatments to enhance this property. This is specially important for nets used near agricultural areas or industrial sites, the place chemical runoff could compromise weaker materials.

4. Biodegradability (Controlled vs. Non-Biodegradable)

Some 3D vegetation nets are designed to biodegrade over time, acting as a brief support until vegetation matures. These are made with plant-based polymers or blends that spoil down in 1-3 years. Non-biodegradable options, however, provide permanent reinforcement—ideal for steep slopes the place vegetation alone can’t prevent erosion. When choosing, think about project timelines: temporary initiatives may benefit from biodegradable nets, whilst permanent Geomat for Slope Protection systems require non-biodegradable durability.

How Specifications Impact Application: From Installation to Long-Term Performance

3D vegetation internet specifications aren’t just technical details—they immediately influence how the net features in real-world scenarios.

1. Installation: Ease of Laying 3D Vegetation Net

Lightweight PP nets are easier to transport and Lay 3D vegetation net on uneven terrain, lowering labor costs. Their flexibility allows them to conform to slopes without tearing, making sure full soil coverage. In contrast, heavier PET nets may require more gear for installation but provide better anchoring in high-wind or high-water areas.

2. Compatibility with Vegetation Growth

The net’s material porosity is a key specification. Too dense, and water/oxygen can’t attain seeds; too loose, and soil particles wash away. 3D structures with 80-90% porosity strike the balance, creating a microenvironment the place grass, shrubs, or native plants thrive. This makes them a superior choice to erosion control geomat, which often lacks the identical vegetation-supporting design.

3. Synergy with Geomat for Slope Protection

For extreme slopes (over 30 degrees), combining 3D vegetation nets with Geomat for Slope Protection enhances stability. The 3D net’s matrix traps soil, while the geomat provides an extra layer of reinforcement. When selecting materials, make certain both products have well suited durability ratings—e.g., a UV-resistant PET net pairs nicely with a high-tensile geomat for long-term slope protection.

Choosing the Right 3D Vegetation Net: Key Questions to Ask

To healthy specifications to your challenge needs, consider these factors:

1.Environment: Will the internet face severe UV rays, heavy rainfall, or chemical exposure? Prioritize UV-resistant PET for sunny areas.

2.Project timeline: Temporary stabilization (1-3 years) works with biodegradable PP; everlasting projects desire non-biodegradable blends.

3.Slope angle: Steeper slopes require higher tensile electricity (20+ kN/m) to face up to soil movement.

4.Vegetation type: Fast-growing grasses want high porosity; deep-rooted shrubs tolerate barely denser nets.

Conclusion: Invest in Quality Specifications for Lasting Erosion Control

Understanding 3D vegetation web specifications—materials and durability—isn’t just about compliance; it’s about ensuring your erosion manage undertaking stands the test of time.Whether you’re getting prepared to Lay 3D vegetation net on a dual carriageway embankment or evaluating picks to erosion control geomat, prioritizing UV resistance, tensile strength, and material compatibility will minimize protection expenses and maximize soil stability. By aligning specs with your project’s unique challenges, you’ll create a resilient, vegetation-rich landscape that protects in opposition to erosion for years to come.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person : Jaden Sylvan

Contact Number : +86 19305485668

WhatsApp: +86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province