Top 5 Applications of Cement Blankets in Construction

The development enterprise is present process a paradigm shift with the adoption of cement blankets—a modern fabric that combines the sturdiness of concrete with the flexibility of fabric. Known interchangeably as cement canvas or Concrete Cloth, this geosynthetic cementitious composite mat (GCCM) hardens upon hydration to structure a thin, waterproof, and fire-resistant concrete layer. Its "concrete-on-a-roll" plan eliminates the want for usual mixing, casting, and curing processes, lowering labor fees through up to 50% and slicing task timelines by way of 70%. This article explores the pinnacle 5 functions of cement blankets in current construction, highlighting their versatility, cost-efficiency, and environmental benefits.

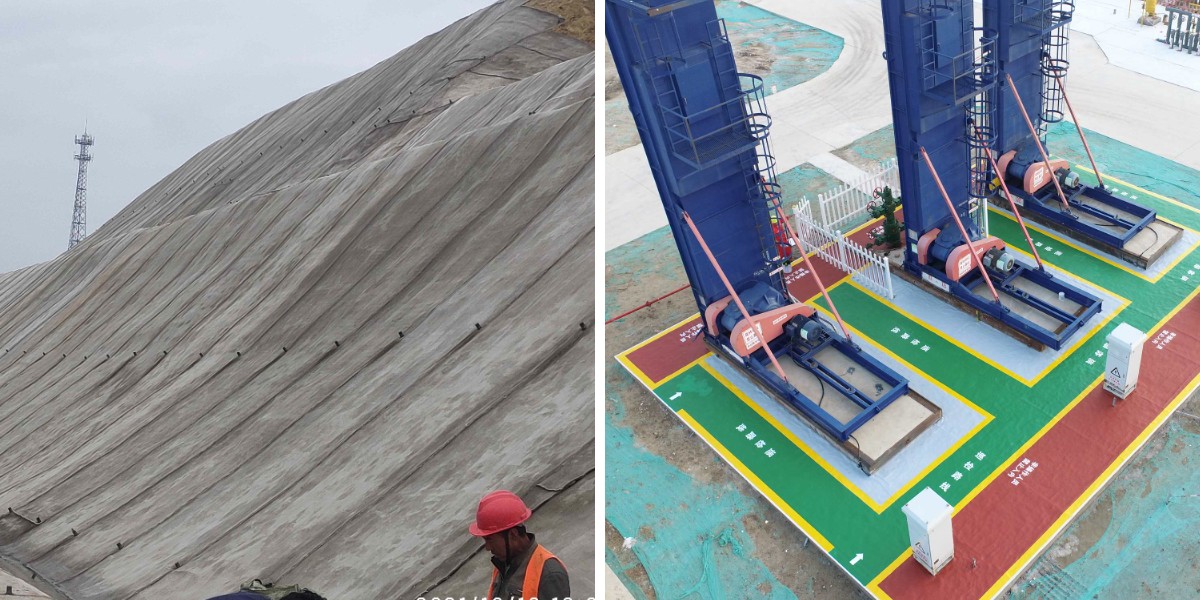

1. Slope Protection and Erosion Control

Cement canvas has emerged as a game-changer in slope stabilization, specially in areas inclined to soil erosion or landslides. Traditional techniques like shotcrete require heavy equipment and knowledgeable labor, whereas Concrete Cloth can be unrolled and anchored at once onto slopes. Its excessive tensile strength—enhanced via aramid fiber reinforcement—enables it to stand up to dynamic masses and heavy rainfall.

A 2019 find out about posted in ScienceDirect in contrast cement canvas with shotcrete for slope protection. The effects confirmed that FRP-reinforced Concrete Cloth finished enough balance for slopes underneath 10 meters in height, with quicker electricity improvement and decrease environmental impact. For example, a dual carriageway assignment in China used cement canvas to stabilize a 1:1.5 slope, lowering development time from 14 days to simply three days whilst doing away with the want for formwork or vibration compaction.

Key Advantages:

Rapid Installation: Unroll, anchor, and hydrate—no mixing or curing delays.

Environmental Resilience: Withstands UV exposure, freeze-thaw cycles, and chemical corrosion.

Cost-Effective: Reduces cloth waste and labor charges by using up to 40%.

2. Channel Lining and Drainage Systems

Water administration infrastructure, such as irrigation channels, stormwater drains, and culverts, needs durable, impermeable linings to forestall leakage and soil erosion. Cement canvas affords a seamless, monolithic lining that conforms to irregular terrain, doing away with joints that are prone to water infiltration.

In a 2024 challenge in India, engineers used Concrete Cloth to line a 500-meter irrigation channel with a 2% slope. The fabric used to be laid in sections, overlapped by means of 10 cm, and secured with stainless metal screws. After hydration, the lining carried out a compressive power of 30 MPa inside 24 hours, in contrast to 7 days for traditional concrete. The venture mentioned a 60% discount in water loss and a 50% decrease carbon footprint due to minimized cement usage.

Application Tips:

Slope Preparation: Ensure a easy substrate to keep away from uneven settling.

Hydration Control: Use sprinklers for uniform water distribution; keep away from high-pressure jets that can also harm the fabric.

Joint Sealing: Apply silicone sealant at overlaps to decorate waterproofing.

3. Emergency Repairs and Disaster Relief

Natural failures such as floods, earthquakes, and hurricanes regularly harm essential infrastructure, requiring rapid, brief repairs. Cement canvas’s portability and speedy curing make it perfect for emergency scenarios.

During the 2023 floods in Bangladesh, alleviation groups deployed Concrete Cloth to restore breached dikes and levees. The cloth was once air-dropped in rolls, unrolled over broken sections, and hydrated the usage of nearby water sources. Within 6 hours, the repairs performed enough power to stand up to in addition flooding, shopping for time for everlasting solutions. Similarly, the U.S. Army Corps of Engineers has adopted cement canvas for speedy runway repairs in fight zones, lowering downtime from days to hours.

Why It Works:

Lightweight: A 10 mm-thick roll weighs simply 1.6 kg/m², enabling convenient transport by means of helicopter or truck.

All-Weather Performance: Hardens even in sub-zero temperatures when combined with heat water.

Non-Toxic: Safe for use in potable water systems, as tested by way of NSF/ANSI sixty one certification.

4. Temporary and Permanent Flooring

Construction sites, industrial facilities, and match venues frequently require long lasting but detachable floor solutions. Cement canvas provides a semi-permanent choice to typical concrete slabs, with the flexibility to be deconstructed and reused.

A 2025 warehouse undertaking in Germany used Concrete Cloth to create a 2,000 m² loading dock floor. The cloth used to be laid over a compacted gravel base, hydrated, and completed with a non-slip coating. After 18 months of heavy forklift traffic, the flooring confirmed no cracking or wear, outperforming the predicted lifespan of 5 years. When the warehouse used to be repurposed, the cement canvas was once eliminated in sections and recycled into combination for new construction.

Design Considerations:

Thickness Selection: Opt for 10–15 mm rolls for heavy-duty applications; 5 mm for light-weight pedestrian paths.

Surface Finish: Add epoxy coatings for chemical resistance or combination declares for anti-slip properties.

Reusability: Store unused rolls in a dry surroundings to hold hydration potential.

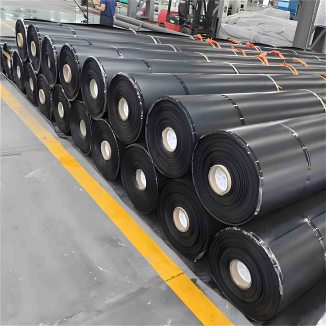

5. Concrete Curing Blankets for Enhanced Strength Development

While cement canvas revolutionizes concrete application, cement curing blankets are remodeling the curing manner itself. Traditional curing strategies depend on moist burlap or plastic sheeting, which are labor-intensive and inclined to uneven moisture distribution. Cement curing blankets, such as these supplied by way of Warmzone and Tarps Now, use superior insulation substances to alter temperature and humidity, making sure most reliable hydration.

How Cement Curing Blankets Work

These blankets function a multi-layer design:

Outer Layer: Durable PVC or polyethylene for waterproofing and UV resistance.

Insulation Core: Closed-cell foam or fiberglass to maintain warmness and moisture.

Inner Layer: Absorbent cloth to distribute water evenly throughout the concrete surface.

In a 2025 trial by way of the California Department of Transportation, cement curing blankets have been used on a dual carriageway bridge deck. The blankets maintained a regular 20°C curing temperature, even in 5°C ambient conditions, ensuing in a 40% quicker energy obtain in contrast to uncovered concrete. The assignment additionally pronounced a 30% discount in cracking due to elevated moisture retention.

Types of Cement Curing Blankets

Passive Blankets: Insulate concrete the usage of reflective substances or thermal barriers. Ideal for average climates.

Heated Blankets: Incorporate electric powered heating factors to speed up curing in bloodless weather. Models like the 120V Big Concrete Curing Blanket from Wuxi Hengdeying attain temperatures up to 60°C, decreasing curing time through 75%.

Hybrid Blankets: Combine insulation with moisture-retention layers for all-season use.

Best Practices:

Timing: Apply blankets at once after concrete ending to forestall untimely drying.

Sealing: Use tape or straps to create an hermetic seal round edges.

Monitoring: Install temperature sensors to song curing growth in actual time.

Conclusion: The Future of Cement Blankets in Construction

From slope safety to catastrophe relief, cement canvas and cement curing blankets are redefining effectivity and sustainability in construction. Their capability to limit labor, cloth waste, and carbon emissions aligns flawlessly with world tendencies towards inexperienced constructing practices. As producers like Huai’an Hanji and Taian Nuolian proceed to innovate, we can assume these substances to come to be widespread equipment in each and every civil engineer’s toolkit.

Whether you’re stabilizing a mountainside, repairing a flood-damaged dike, or curing a bridge deck in winter, Concrete Cloth and its curing counterparts provide a smarter, faster, and greener way to build. Embrace the revolution—your initiatives (and the planet) will thank you.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province