Step-by-Step HDPE Geocell Installation Guide: Grid Expansion, Anchoring & Infill Tips

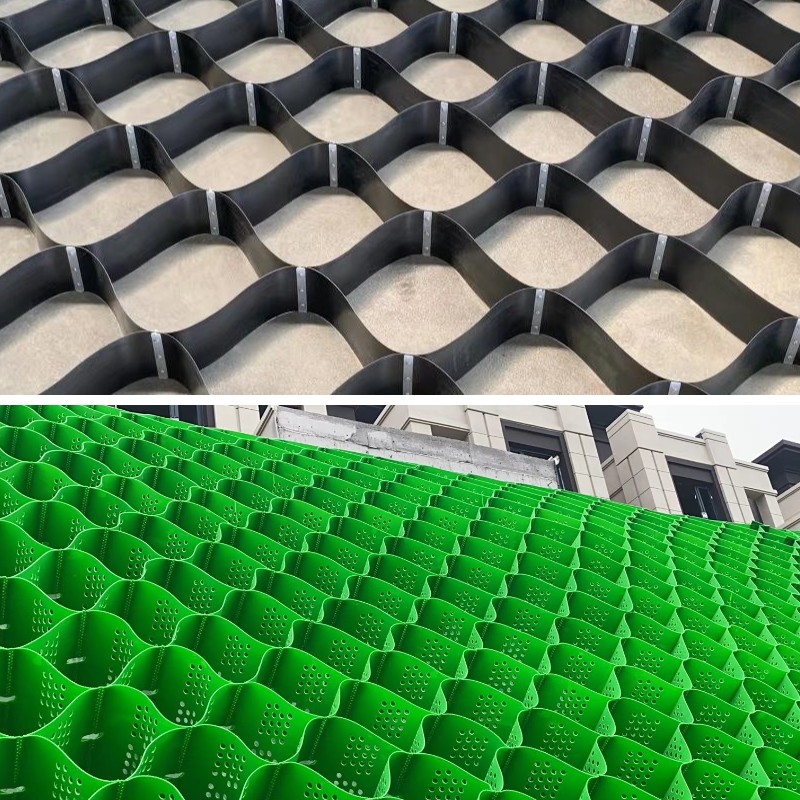

In slope stabilization, street construction, and gentle soil reinforcement projects, HDPE Geocell has end up a desired geosynthetic cloth due to its extremely good load-bearing capacity, corrosion resistance, and effortless installation. As a three-d honeycomb shape made of high-density polyethylene, Geocell efficiently restricts soil movement, enhances basis stability, and is mainly broadly used in geocell slope safety projects. However, fallacious set up can considerably minimize its performance. This step-by-step information important points the complete HDPE Geocell set up process, along with pre-installation preparation, grid expansion, anchoring, infill, and post-installation maintenance, assisting contractors and engineers make sure development exceptional and assignment durability.

1. Pre-Installation Preparation: Lay the Foundation for Successful Installation

Adequate pre-installation instruction is vital to keep away from delays and exceptional troubles in the course of the set up process. This stage on the whole consists of three core tasks: cloth inspection, base floor treatment, and device preparation. Each hyperlink is carefully associated to the closing set up impact of HDPE Geocell.

1.1 Material Inspection & Storage Check

First, check out the HDPE Geocell rolls to make certain they meet challenge specifications. Check for harm such as cracks, holes, or tears on the floor of the geocell sheets—these defects will weaken the structural energy and have an effect on its reinforcement effect. At the identical time, verify the thickness, width, length, and cellphone measurement of the geocell towards the shipping listing and plan drawings. For geocell slope safety projects, pay specific interest to the material’s anti-ultraviolet (UV) resistance and low-temperature flexibility, as these homes decide its carrier existence in out of doors and harsh environments.

In phrases of storage, HDPE Geocell must be saved in a dry, ventilated vicinity away from direct daylight and excessive temperatures. Avoid setting heavy objects on the rolls to forestall deformation of the telephone structure. If saved exterior temporarily, use a water resistant and UV-resistant tarpaulin to cowl the rolls to avoid getting old induced via long-term publicity to rain and sunlight.

1.2 Base Surface Treatment: Ensure Flatness & Stability

The base floor the place Geocell is hooked up have to be flat, compact, and free of sharp objects. First, put off all debris, stones, tree roots, and weeds from the base surface—sharp objects can pierce the HDPE fabric and purpose damage. Then, compact the base soil the usage of a compactor, with a compaction diploma of now not less than 95% (for street subgrade and slope safety projects) to make sure the base does now not settle after geocell installation.

For sloped surfaces (common in geocell slope protection), the slope gradient have to be adjusted in accordance to the sketch requirements. If the slope is too steep, it might also be indispensable to degree the slope first or deploy extra anchoring units to forestall the geocell from sliding. In addition, if the base floor has water accumulation problems, a drainage device must be set up in improve to keep away from long-term immersion of the geocell affecting its performance.

1.3 Tool & Auxiliary Material Preparation

Prepare the vital equipment and auxiliary substances earlier than set up to enhance building efficiency. Common equipment include: a utility knife (for slicing geocell sheets), a tape measure (for measuring dimensions), a compactor (for compacting the base and infill materials), and a hammer (for putting in anchoring pins). Auxiliary substances include: anchoring pins (preferably HDPE or galvanized metal to make sure corrosion resistance), connecting clips (for becoming a member of a couple of geocell sheets), and infill substances (such as gravel, sand, or concrete, chosen in accordance to undertaking needs).

2. Step-by-Step HDPE Geocell Installation: From Grid Expansion to Infill

The formal set up manner of HDPE Geocell is divided into three key steps: grid expansion, anchoring fixation, and infill compaction. Each step has strict operational requirements, and wrong operation may additionally lead to structural instability of the geocell.

2.1 Grid Expansion: Ensure Uniform Cell Opening

First, unroll the HDPE Geocell roll on the organized base surface, and align it with the project’s layout course (for slope protection, the geocell’s growth course ought to be perpendicular to the slope’s contour line to beautify stability). Then, slowly increase the geocell grid to structure a normal honeycomb structure. During expansion, make sure that every cellphone is completely opened and the geocell sheet is flat besides wrinkles or folds—wrinkles will motive uneven stress distribution and have an effect on the reinforcement effect.

If the challenge vicinity is large than the measurement of a single geocell sheet, more than one sheets want to be connected. When connecting, align the edges of the two sheets and use connecting clips to repair them each and every 30-50 cm. Ensure the connection is association to keep away from separation throughout infill and use. For geocell slope safety projects, the overlapping width of the linked sheets ought to now not be much less than 10 cm to decorate the general balance of the geocell system.

2.2 Anchoring Fixation: Prevent Sliding & Shifting

Anchoring is a key step to make certain the Geocell does now not slide or shift throughout use, in particular for slope safety projects. The anchoring manner need to be carried out straight away after grid enlargement to keep away from the geocell returning to its rolled state.

First, set up anchoring pins at the 4 corners of the geocell sheet—use longer anchoring pins (length ≥ 30 cm) for gentle soil or sloped surfaces to make certain they penetrate the base soil firmly. Then, installation anchoring pins alongside the edges of the geocell at intervals of 50-80 cm. For the center place of the geocell sheet, anchoring pins can be established at intervals of 1.5-2 meters in accordance to the base soil conditions. When putting in the anchoring pins, make sure they are perpendicular to the base floor and completely inserted into the soil to keep away from loosening.

For geocell slope safety with a slope gradient increased than 30 degrees, extra anchoring measures are required. For example, deploy a reinforcement strip alongside the slope’s pinnacle part and repair it with anchoring bolts, or bury the pinnacle part of the geocell into a pre-dug trench (depth ≥ 20 cm) and backfill it with compacted soil to beautify the anti-sliding capacity.

2.3 Infill & Compaction: Ensure Structural Stability

After the HDPE Geocell is anchored firmly, the infill cloth can be added. The desire of infill cloth relies upon on the project’s purpose: for avenue subgrade reinforcement, gravel or graded sand is commonly used; forgeocell slope protection, a combination of soil and gravel (or planting soil for ecological slope protection) is suitable; for high-load-bearing areas such as parking lots, concrete infill can also be required.

When infilling, add the fabric evenly into the geocell cells to keep away from uneven stress triggered through partial overfilling. The infill top need to be flush with the pinnacle of the geocell or 2-3 cm greater than the pinnacle (to compensate for compaction settlement). After infilling, use a compactor to compact the infill material. The compaction ought to be carried out in layers, with a compaction diploma of now not much less than 96% to make sure the infill fabric is intently blended with the geocell, forming a steady composite structure.

Note that at some stage in compaction, the compactor ought to no longer immediately roll over the geocell’s edges or connecting components to keep away from adverse the geocell material. For slope surfaces, use a small hand compactor for compaction to make certain the infill cloth is utterly compacted besides inflicting the geocell to slide.

3. Post-Installation Quality Inspection & Maintenance Tips

After the set up is completed, first-rate inspection and ordinary renovation are vital to make sure the long-term overall performance of the HDPE Geocell system. This stage in most cases consists of set up fine acceptance and each day maintenance.

3.1 Installation Quality Inspection Standards

The pleasant inspection need to center of attention on the following aspects: 1) The geocell grid is utterly expanded, and the cells are uniform in dimension besides deformation; 2) The connection between geocell sheets is firm, with no separation or loosening; 3) The anchoring pins are entirely inserted into the soil, and there is no loosening or tilting; 4) The infill cloth is evenly disbursed and thoroughly compacted, with no hole areas; 5) For geocell slope protection, the geocell gadget is intently connected to the slope surface, with no gaps or sliding signs.

If fantastic issues are determined (such as free anchoring, uneven infill, or broken geocell sheets), well timed rectification is required. For example, re-install free anchoring pins, complement infill cloth in hole areas, or reduce out broken components and substitute them with new geocell sheets (ensuring association connection with the unique sheets).

3.2 Long-Term Maintenance Tips

Regular renovation can prolong the provider existence of Geocell. For out of doors initiatives such as geocell slope protection, look into the geocell machine each and every 6 months (or after heavy rain, robust winds, or different intense weather). Check for harm to the geocell material, loosening of anchoring pins, and loss of infill material. If harm is found, restore it in time—small holes can be included with HDPE restore tape, whilst massive broken areas want to be changed with new sheets.

In addition, avoid heavy equipment or cars immediately rolling over the geocell edges for a lengthy time. For ecological slope safety initiatives the use of geocell, typically preserve the planted vegetation to make certain the vegetation roots are carefully interwoven with the geocell and infill material, similarly improving slope stability.

Conclusion

The right set up of HDPE Geocell is the key to exerting its reinforcement and safety functions, specifically in geocell slope safety and street subgrade projects. By following the pre-installation preparation, step-by-step set up (grid expansion, anchoring, infill), and post-installation renovation steps special in this guide, you can make certain the set up best of the geocell system, enhance assignment durability, and limit long-term protection costs.

If you are task a geocell-related venture and want customized set up recommendation or remarkable HDPE Geocell products, sense free to contact our expert team. We furnish one-stop options along with product customization, technical guidance, and on-site development aid to assist you whole the mission efficiently.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province