Step-by-Step Guide: Installing Cement Blanket Underwater for Dam & Canal Repairs

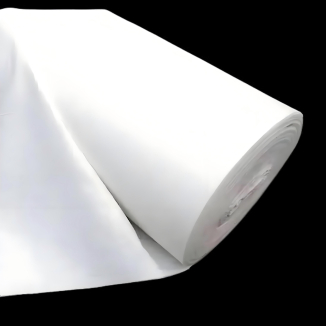

Underwater injury to dams and canals—from erosion, cracks, or structural wear—threatens water containment, environmental safety, and infrastructure longevity. Traditional restore strategies (like diver-led concrete pouring) are costly, time-consuming, and risky. Enter cement blanket (also acknowledged as concrete canvas or concrete fabric fabric): a flexible, water-activated fabric that hardens into long lasting concrete, making it best for underwater repairs. Below is a specified information to installing cement blanket underwater, overlaying prep, floor work, installation, and post-care to make sure a successful, long-lasting fix.

1. Pre-Installation Prep: Lay the Groundwork for Success

Thorough pre-installation steps are non-negotiable to make sure your concrete canvas adheres properly, hardens evenly, and addresses the root of the damage. Start with a distinctive underwater assessment—use divers or remote-operated vehicles (ROVs) to map the injury area, noting its depth, size, and shape. For example, a 2ft-wide crack in a dam’s base wishes a cement blanket large adequate to cowl the crack plus 12–18 inches of surrounding intact surface, stopping water seepage beneath edges. You’ll additionally want to test water conditions: purpose for currents below 1 knot (faster flows shift the blanket), temperatures between 50–77°F (optimal for concrete fabric fabric hydration), and clear water (for effortless positioning). Identify barriers like rocks or particles too—these will want elimination later to keep away from uneven placement.

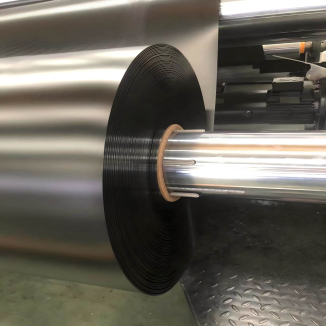

Next, calculate fabric desires and pick out the right cement blanket. Choose merchandise rated for underwater use (look for water resistant backings and excessive tensile strength, such as Concrete Canvas CC8 or CC13). Add 1–2 ft of more fabric to the injury area’s dimensions, and account for 6–8 inch overlaps if the use of a couple of rolls. Finally, acquire equipment and protection gear: ROVs or underwater cameras for real-time positioning, diver equipment (utility knives for trimming cement blanket, weighted anchors, brushes for smoothing), protection gear (dive suits, oxygen tanks, conversation devices), and floor tools (winches/cranes for decreasing the blanket except tearing, a hydration station for bloodless water conditions).

2. Prepare the Underwater Surface: Create a Smooth, Clean Base

A clean, even floor is crucial for cement blanket adhesion—debris, unfastened concrete, or uneven terrain creates gaps the place water seeps, ruining the repair. Start by means of getting rid of particles and unfastened material: divers or ROVs use low-pressure water jets to blast away silt, algae, and sediment, and hydraulic equipment to clear large gadgets like rocks or damaged concrete. Even small stones can reason bumps, so thorough cleansing is key.

Next, clean uneven surfaces. Divers use grinders or chisels to stage difficult patches, aiming for a floor with no extra than ¼-inch top variation—this ensures full contact with the concrete canvas. For deep cracks (>1 inch wide), fill them with quick-setting underwater mortar first, then let it therapy 24–48 hours earlier than putting in the blanket. This prevents the blanket from sinking into the crack and creates a secure base. If dealing with robust currents or smooth sediment, installation transient weighted edging (metal strips or sandbags) round the region to anchor the concrete fabric fabric’s edges throughout installation.

3. Underwater Installation: Position, Hydrate, and Secure the Cement Blanket

Installing cement blanket underwater requires tight coordination between floor groups and divers/ROVs to avoid tearing, misalignment, or air pockets. Begin via decreasing the blanket into the water: floor groups use a crane or winch with a smooth sling to decrease the concrete canvas roll slowly—fast decreasing motives folding or tearing. For giant rolls, connect information ropes to corners (controlled by means of divers) to steer it to the harm area; in no way drag the blanket alongside the water floor, as this scrapes off the dry concrete combine inside.

Once in place, function the blanket and do away with air bubbles. Divers or ROVs maneuver it over the harm area, making sure full insurance plus the 1–2ft overlap. Use underwater cameras to affirm alignment—even a 1-inch shift leaves cracks exposed. Then, divers clean the blanket from core outward with brushes or arms to push out air bubbles (these create voids in hardened concrete) and make certain tight adhesion.

Hydrate the cement blanket if needed: most set off routinely in water, however in bloodless stipulations (<50°F) or low-turbidity water, divers spray a exceptional mist from a surface-fed hose to kickstart hydration—avoid over-saturating, as extra water washes away concrete mix. For blankets with water resistant backings, peel it off (if required) per producer instructions—some dissolve automatically. Finally, invulnerable the blanket with anchors: vicinity weighted anchors (concrete or metal) alongside edges and each and every 3–4 toes throughout the floor to maintain it in region whilst curing (24–72 hours, relying on temperature). For overlapping rolls, double-anchor seams each two toes to forestall seepage.

4. Post-Installation Curing & Inspection: Ensure Long-Term Durability

Proper curing and inspection verify the cement blanket hardened successfully and the restore is watertight. Start by way of monitoring curing progress: use underwater temperature sensors to song inner heat—consistent 50–77°F ensures full curing. Avoid stressful the blanket for seventy two hours; prolong to ninety six hours in bloodless water, as slower hydration builds strength.

Next, habits leak tests: pump water into the place above the restore and use ROVs/cameras to test for leaks. For dams or canals, repair water waft steadily over forty eight hours. If leaks show up (water seeping beneath the concrete canvas), patch with a small cement blanket piece and re-cure.

Schedule normal inspections too: take a look at month-to-month for 6 months, then quarterly. Look for tears, peeling edges, or new cracks—early fixes forestall predominant issues. For high-traffic canals, use sonar yearly to scan the concrete material fabric’s floor and discover hidden damage.

Final Tips for Success

Choose the proper product: Opt for cement blanket with ASTM D751 certification (water resistance) and ≥3,000 psi compressive power (when cured).

Train the team: Ensure divers and ROV operators understand how to handle concrete canvas—small errors (like tearing) wreck repairs.

Watch the weather: Avoid storms or excessive winds—surface turbulence makes decreasing hazardous and disrupts positioning.

By following these steps, you’ll use cement blanket to create a fast, cost-effective, and long lasting underwater repair. Whether fixing a dam crack or eroded canal wall, concrete material fabric delivers the reliability wanted to defend vital water infrastructure for years.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province