Secondary Containment with Geomembranes: Safeguarding Against Spills in Industrial Facilities

Introduction: The Critical Need for Industrial Spill Prevention

In today’s industrial landscape, the penalties of chemical spills, gasoline leaks, or hazardous cloth releases can be catastrophic. Beyond extreme environmental injury and regulatory fines, such incidents pose great dangers to human health, company reputation, and operational continuity. Proactive secondary containment has advanced from a endorsed exercise to a necessary issue of accountable facility management. At the coronary heart of modern, dependable containment structures lies a effective engineering solution: the tightly closed geomembrane. This article explores how superior geomembrane science types the crucial barrier in secondary containment strategies, making sure amenities can function safely and in compliance with stringent environmental regulations.

Understanding Secondary Containment Systems

Secondary containment refers to a defensive device that serves as a backup to most important storage containers, such as tanks, drums, or pipelines. Its sole reason is to safely confine any spilled or leaked hazardous beverages till they can be precise removed, stopping migration into soil, groundwater, or surrounding waterways. An superb gadget commonly consists of a robust, impermeable liner established below and round storage areas, regularly built-in with berms or dikes to create a catchment basin.

The layout ought to account for elements like chemical compatibility, quantity capability (often 110% of the biggest essential container), and durability. This is the place engineered geomembrane for landfill purposes has furnished helpful lessons; the identical core ideas of long-term fluid isolation and environmental safety are immediately transferable to industrial settings, albeit with one-of-a-kind chemical and operational stresses.

The Role of Impervious Geomembranes as the Primary Barrier

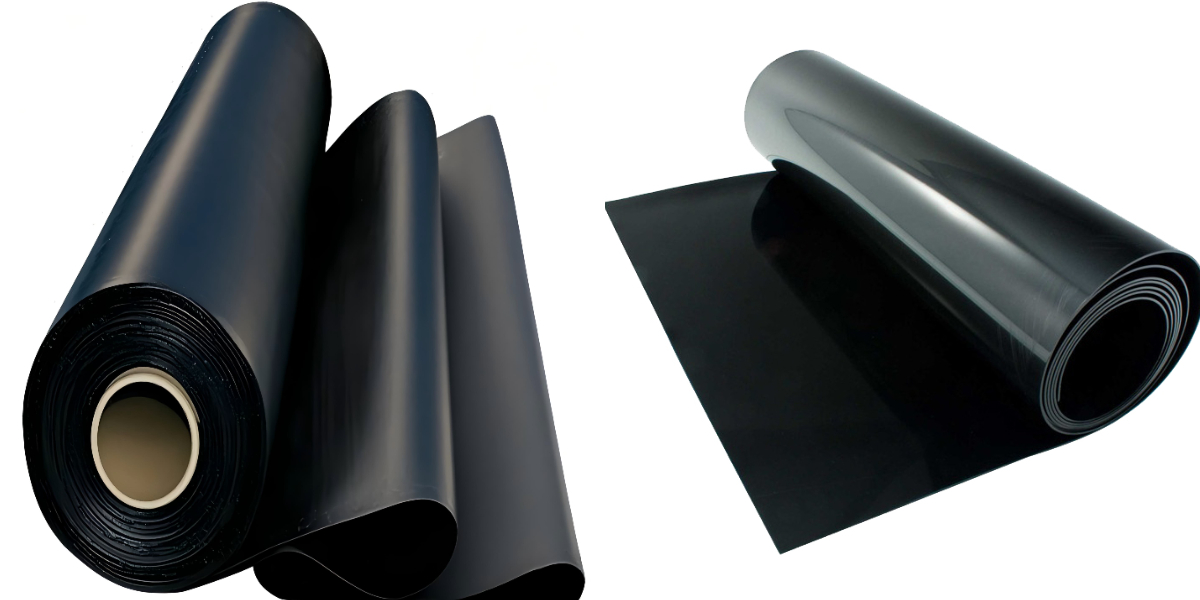

An invulnerable geomembrane is a synthetic, continuous, and very low-permeability liner or barrier. Its major characteristic is to forestall the passage of beverages or vapors. In secondary containment, it acts as the critical, fail-safe layer that incorporates a spill inside a unique area.

Modern geomembranes are manufactured from a variety of polymer resins, consisting of HDPE (High-Density Polyethylene), LLDPE (Linear Low-Density Polyethylene), PVC (Polyvinyl Chloride), and bolstered polypropylene geomembrane. The determination relies upon on the unique chemical substances stored, temperature ranges, set up conditions, and required mechanical strength. The key attribute is impermeability—creating a reliable, monolithic barrier that does no longer permit contaminants to seep via its matrix, a precept perfected in geomembrane for landfill caps and base liners the place leachate containment is paramount.

Key Advantages of Geomembrane-Based Containment

1. Superior Chemical Resistance: High-quality geomembranes are formulated to face up to a huge vary of aggressive chemicals, acids, alkalis, and hydrocarbons. This ensures the integrity of the containment mobile is maintained even in the course of a great spill event.

2. Long-Term Durability and Low Permeability: A excellent mounted impenetrable geomembrane presents a long time of carrier with minimal maintenance. Its engineered resistance to ultraviolet (UV) light, oxidation, and environmental stress cracking is imperative for uncovered applications. The extraordinarily low permeability coefficient (effectively zero for realistic purposes) gives peace of thought that even small, continual drips will no longer pass by through.

3. Customization and Seam Integrity: Geomembranes can be factory-fabricated into massive panels, minimizing discipline seams. Advanced thermal fusion strategies for substances like HDPE create seams as sturdy as the dad or mum sheet, making sure a monolithic, leak-proof system. This is a necessary technological know-how borrowed from geomembrane for landfill installations, the place seam integrity is non-negotiable.

4. Cost-Effectiveness: Compared to concrete or compacted clay alternatives, geomembrane structures regularly provide a decrease preliminary price and quicker installation. They additionally supply greater regular and verifiable impermeability than earthen materials.

Material Spotlight: Reinforced Polypropylene Geomembrane

For many industrial secondary containment applications, bolstered polypropylene geomembrane (often distinct as RPP) provides an gorgeous solution. This fabric comprises a mechanical grid or scrim layer embedded between polypropylene layers, presenting first-rate tensile energy and puncture resistance relative to its thickness.

RPP is in particular referred to for its notable chemical resistance throughout a huge pH vary and flexibility in chillier temperatures. Its bolstered nature makes it best for purposes the place subgrade prerequisites can also be uneven or the place some stress is anticipated. When designing containment for aggressive solvents or positive oils, strengthened polypropylene geomembrane gives a strong stability of properties, making sure the secure geomembrane barrier stays intact below challenging conditions.

Design and Installation: Ensuring System Integrity

The overall performance of a secondary containment device hinges on ideal diagram and meticulous installation—a manner with zero tolerance for shortcuts.

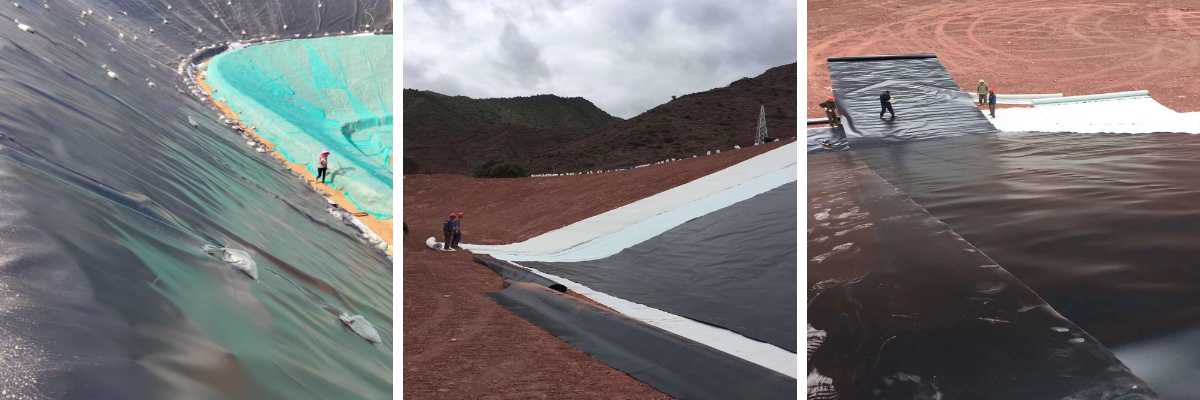

Site Preparation: The subgrade should be true graded, compacted, and free of sharp objects or particles that should puncture the liner. A defensive geotextile cloth is frequently used as a cushioning layer.

Liner Deployment and Seaming: Panels of tightly closed geomembrane are deployed and aligned. Seams are then made the usage of techniques distinct for the cloth (e.g., dual-track fusion welding for HDPE, extrusion welding or adhesive for others). All seams are non-destructively and destructively examined to make certain continuity.

Integration and Details: Critical interest is paid to small print like penetrations (pipes, columns), containment berm walls, and sump areas. These are sealed the use of custom-fabricated geomembrane boots, collars, and patches. The equal rigorous detailing requirements used in a geomembrane for landfill composite liner device are utilized right here to put off susceptible points.

Quality Assurance: A rigorous QA/QC software overseen by means of skilled experts is essential. This consists of fabric testing, seam peel/shear testing, and closing electrical leak area (ELL) surveying to confirm the established liner is free of holes.

Beyond Basins: Applications in Industrial Facilities

Secondary containment with geomembranes is versatile, safeguarding a number of areas inside a facility:

Tank Farms and Drum Storage Areas: Lined impoundments or diked areas round above-ground storage tanks and chemical drum pallets.

Process Areas: Containment pads under piping, valves, pumps, and manufacturing tools the place leaks may want to occur.

Loading/Unloading Racks: Lined pads and curbed areas at switch stations to seize spills from overfills or hose disconnections.

Waste and Washdown Management: Lined trenches, sumps, and maintaining ponds for contaminated stormwater or method washwater.

The engineering philosophy is consistent: installation an invulnerable geomembrane as the most important fluid barrier, simply as a geomembrane for landfill isolates waste from the environment.

Conclusion: An Investment in Protection and Compliance

Implementing a geomembrane-based secondary containment device is a decisive funding in operational integrity, environmental stewardship, and regulatory compliance. It demonstrates a facility’s dedication to stopping air pollution and mitigating risk. Whether utilising a sturdy strengthened polypropylene geomembrane for chemical resistance or any other engineered polymer, the purpose is singular: to create a flawless, invulnerable barrier.

By leveraging applied sciences and set up rigors pioneered in the landfill sector, industrial services can obtain unparalleled spill protection. In a world of growing environmental accountability, a suitable designed and hooked up geomembrane containment machine is no longer simply a security measure—it is a essential pillar of sustainable and accountable industrial operation.

Contact Us

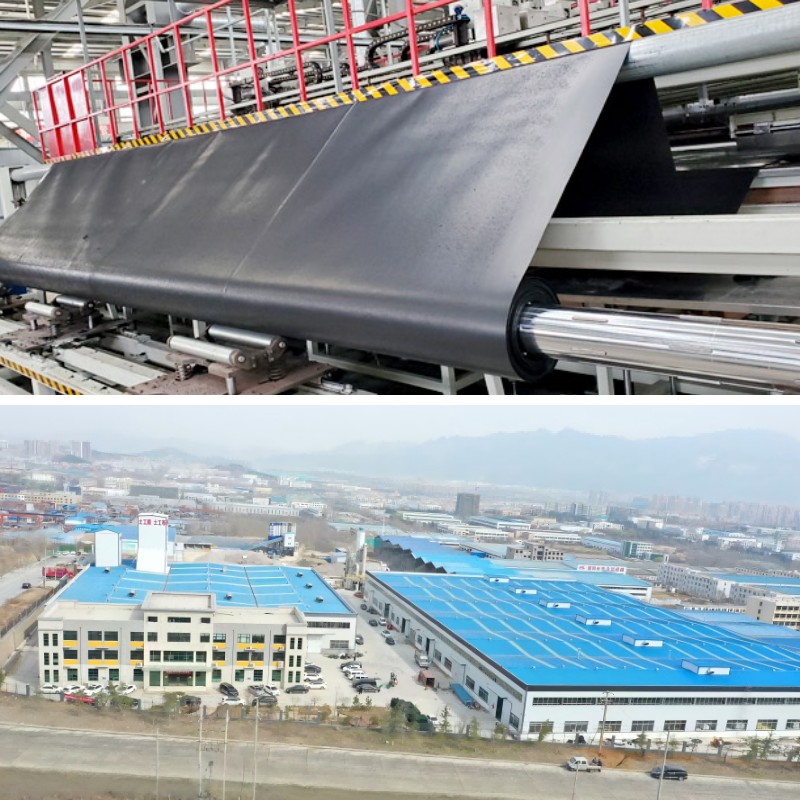

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province