Preventing Water Contamination: Using Geomembranes for Landfill Liners and Caps

Introduction to Geomembrane Technology

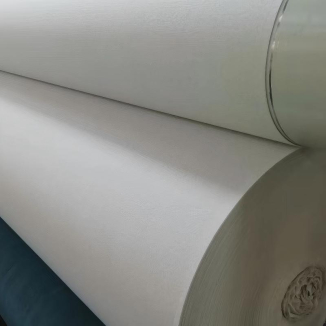

Water illness represents one of the most urgent environmental challenges of our time, with landfills posing a huge danger to groundwater resources. Modern engineering has developed a effective answer to this problem: the geomembrane. These impermeable artificial limitations are the cornerstone of cutting-edge waste containment systems, designed to isolate poisonous leachate and forestall its migration into the surrounding soil and aquifers. Central to this technological know-how is membrane HDPE (High-Density Polyethylene), a cloth prized for its sturdiness and chemical resistance. This article explores the integral position of geomembranes, focusing on the geomembrane liner landfill gadget and the indispensable hdpe lining function in safeguarding our water satisfactory and protecting public fitness from the risks of pollution.

The Threat: Landfill Leachate and Environmental Risk

When precipitation percolates thru waste in a landfill, it creates a poisonous soup recognized as leachate. This liquid includes dissolved and suspended substances from the decomposing waste, along with heavy metals, unstable natural compounds, ammonia, and different hazardous chemicals. Without a sturdy barrier, this leachate can seep into the underlying groundwater, contaminating consuming water sources and disrupting nearby ecosystems. The environmental and fitness dangers are severe, ranging from poisonous publicity to flora and fauna and people to the long-term degradation of precious water resources. It is this grave hazard that makes the principal hdpe lining function—creating an impermeable seal—absolutely non-negotiable in present day sanitary landfill design.

HDPE Geomembranes: The Material of Choice

Among the a number polymers used for containment, membrane HDPE has emerge as the enterprise general for lining landfills. Its giant adoption is due to a top of the line mixture of bodily and chemical properties. HDPE is tremendously impermeable, imparting an nearly zero fee of transmission for drinks and vapors. It possesses exquisite resistance to a vast vary of chemicals, which includes the acidic and alkaline compounds in many instances discovered in leachate. Furthermore, HDPE geomembranes have excessive tensile electricity and puncture resistance, permitting them to face up to the stresses of set up and the long-term load of overlying waste. The sturdiness of this fabric is a key section of its hdpe lining function, as these liners are engineered to function successfully for decades, even in harsh conditions.

Anatomy of a Landfill Liner System

A cutting-edge geomembrane liner landfill device is a sophisticated, multi-layered engineering shape regarded as a composite liner. It is hardly ever a single sheet of HDPE however alternatively a aggregate of complementary substances working in concert. The foremost factor is the membrane HDPE liner itself, which acts as the flexible, impermeable barrier. This is usually established over a layer of compacted clay, which affords secondary containment and extra adsorption capacity. Above the geomembrane, a drainage layer consisting of gravel and perforated pipes is positioned to accumulate leachate and channel it to cure facilities. This complete machine is designed with precision, and the indispensable hdpe lining function inside it is to be the definitive line of defense, making sure that any leachate is accumulated and eliminated as an alternative than being launched into the environment.

The Crucial Role of Landfill Caps

While the base liner prevents downward migration, a landfill ought to additionally be sealed from above as soon as it reaches capacity. This is the place the last cap, or cowl system, comes into play. Much like the base liner, a cap makes use of a membrane HDPE as a necessary component. The fundamental hdpe lining function in a cap is to forestall precipitation from getting into the closed waste cell, thereby minimizing the future era of leachate. A common capping device consists of a layer of soil, a geomembrane barrier, a drainage layer, and topsoil to aid vegetation. By efficiently "putting a lid" on the landfill, the geomembrane cap works in tandem with the base geomembrane liner landfill to create a whole containment unit, separating the waste from the surrounding surroundings for the lengthy term.

Installation: Precision for Maximum Protection

The tremendous overall performance of a geomembrane liner landfill machine is absolutely based on flawless installation. The technique is fantastically technical and requires knowledgeable crews and rigorous first-class assurance. It starts offevolved with getting ready a smooth, steady subgrade free of sharp objects that may want to puncture the liner. Panels of membrane HDPE are then unrolled and located throughout the huge location of the landfill cell. The most integral step is seaming: becoming a member of these large panels collectively the usage of thermal fusion techniques to create a continuous, monolithic barrier except susceptible points. Every inch of each and every seam is examined for integrity, as the standard hdpe lining function is solely as robust as its seams. This meticulous system ensures the liner's integrity and its capability to incorporate contaminants effectively.

Long-Term Performance and Environmental Benefits

The funding in a extremely good geomembrane liner landfill machine can pay dividends for generations thru its long-term environmental benefits. A excellent mounted membrane HDPE liner can have a provider existence exceeding one hundred years, supplying enduring safety for groundwater resources. This prevents the tremendous cleanup prices and public fitness crises related with groundwater remediation. Furthermore, by way of containing methane and different gases inside the waste mass, the liner and cap machine facilitate the series of landfill gas, which can be flared or used as a renewable strength source. The core hdpe lining function of impermeability is consequently no longer simply a shielding measure however a foundational aspect of sustainable, accountable waste administration that balances human endeavor with environmental stewardship.

Conclusion: A Non-Negotiable Safeguard for Water

In conclusion, the use of HDPE geomembranes represents a triumph of environmental engineering. The particular hdpe lining function as an impermeable barrier is the key to mitigating the sizeable air pollution workable of landfills. From the base geomembrane liner landfill machine to the protecting cap, membrane HDPE gives a reliable, durable, and fantastic answer for stopping water contamination. As guidelines come to be stricter and the want for sustainable practices grows greater urgent, the function of this science will solely grow to be greater vital. Investing in perfect geomembrane set up is no longer only a regulatory compliance issue; it is an moral necessary and a indispensable dedication to retaining smooth water for future generations.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province