Oil & Gas Industry: HDPE Geomembranes for Containment and Secondary Spill Protection

Introduction: The Critical Need for Protection in Oil & Gas

The oil and fuel enterprise is the lifeblood of the international economy, powering industries, transportation, and households worldwide. However, it additionally comes with substantial environmental and protection risks. Leakage and spills in this enterprise can have catastrophic consequences, no longer solely for the surroundings however additionally for the financial system and human health.

Oil and fuel leakage can contaminate soil, groundwater, and floor water, main to lengthy - time period injury to ecosystems. For example, a fundamental oil spill in a coastal place can smash marine habitats, kill wildlife, and disrupt the fishing industry. In addition, the cleanup fees of such spills can be astronomical, and the monetary losses to the groups concerned can be giant due to manufacturing disruptions, criminal liabilities, and harm to their reputation.

This is the place HDPE geomembranes come into play. HDPE, or High - Density Polyethylene, is a notable fabric that has revolutionized containment and secondary spill safety in the oil and gasoline industry. An HDPE geomembrane is a thin, flexible, and fairly impermeable sheet made from HDPE resin. It acts as a barrier, stopping the leakage of oil, gas, and different probably hazardous resources from storage tanks, pipelines, and waste disposal sites.

Impermeable geomembrane liners, like these made from HDPE, are necessary factors in the infrastructure of oil and fuel facilities. They are designed to be resistant to the corrosive nature of oil and gas, as properly as to environmental elements such as UV radiation, temperature variations, and chemical exposure. These liners supply an extra layer of protection, minimizing the hazard of leakage and making sure the security and sustainability of oil and fuel operations.

What Are HDPE Geomembranes?

Definition and Composition

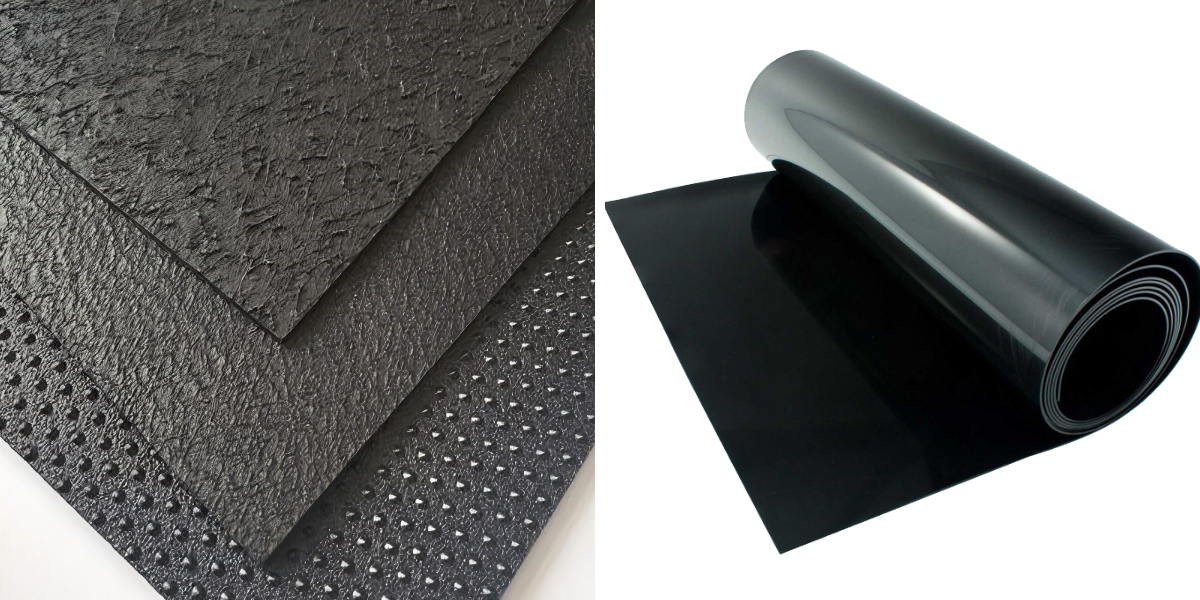

HDPE geomembranes are thin, bendy sheets made from High - Density Polyethylene. HDPE is a thermoplastic polymer derived from ethylene gasoline via a polymerization process. The "high - density" in its identify refers to its fairly excessive diploma of crystallinity, which is finished with the aid of a decrease quantity of branching in its molecular shape in contrast to different kinds of polyethylene, such as Low - Density Polyethylene (LDPE).

The molecular shape of HDPE is composed of lengthy chains of carbon atoms, with hydrogen atoms connected alongside the size of these chains. The absence of extensive branching lets in the polymer chains to pack intently together, ensuing in a cloth with excessive density, strength, and remarkable impermeability. This special molecular association is the key to the terrific overall performance of HDPE geomembranes.

HDPE geomembrane fabric is produced through melting HDPE resin pellets and then extruding or calendering them into the preferred sheet thickness. The manufacturing method can be exactly managed to make certain regular best and houses throughout the whole product. The thickness of HDPE geomembranes can differ depending on the particular software requirements, generally ranging from 0.5mm to 2.5mm or more.

Key Properties of HDPE Geomembranes

1. High Impermeability: One of the most necessary homes of HDPE geomembranes is their magnificent impermeability. As an impermeable geomembrane liner, HDPE has an extraordinarily low permeability coefficient, which capability it can correctly stop the passage of beverages and gases. This property makes it best for containing oil, gas, and different doubtlessly dangerous substances. Whether it is used in the lining of oil storage tanks or round pipelines, HDPE geomembranes act as a dependable barrier, minimizing the danger of leakage and defending the surrounding environment.

2. Chemical Stability: HDPE geomembranes are notably resistant to a broad vary of chemicals. They can face up to the corrosive outcomes of oil, gasoline, diesel, and quite a number chemical components current in the oil and fuel industry. This chemical balance ensures that the geomembranes hold their integrity over time, even when in contact with aggressive substances. For example, in a refinery the place extraordinary chemical procedures are taking place, HDPE geomembranes used in waste containment areas can undergo the harsh chemical surroundings except degradation.

3. Durability: HDPE geomembranes are acknowledged for their lengthy - time period durability. They can face up to environmental elements such as UV radiation, temperature variations, and mechanical stress. Special components can be included at some point of the manufacturing technique to beautify their resistance to UV rays, permitting them to be used in outside purposes for prolonged periods. Additionally, their flexibility and durability allow them to face up to minor floor moves and impacts, in addition contributing to their lengthy - lasting overall performance in oil and gasoline facilities.

Function in Containment Systems

Primary Containment

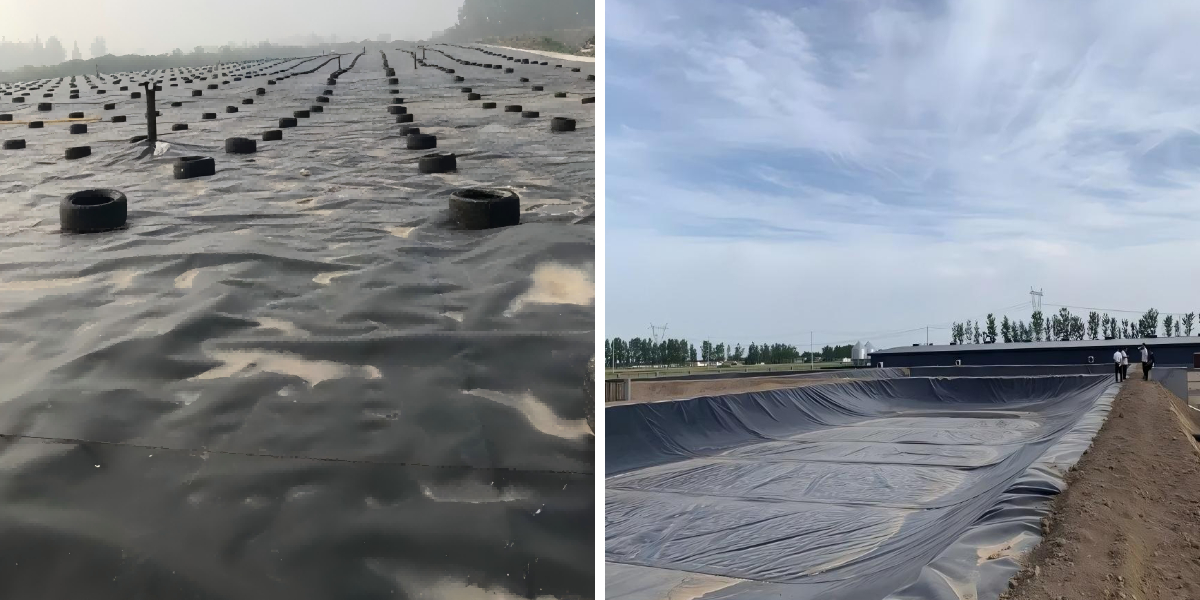

In the oil and fuel industry, principal containment structures are the first line of protection towards the leakage of oil, gas, and different substances. HDPE geomembranes play a essential function in these systems, in particular in purposes such as oil storage tanks and massive - scale water storage reservoirs.

In oil storage tanks, HDPE geomembranes are frequently used as liners. They are mounted at the backside and now and again on the internal partitions of the tanks. The easy and non-stop floor of the HDPE geomembrane creates a seamless barrier. When oil is saved in the tank, the HDPE geomembrane prevents the oil from seeping thru the tank's structure. This is crucial due to the fact any leakage from the tank may want to lead to soil contamination, groundwater pollution, and workable hearth hazards. For example, in an on - shore oil storage facility, the HDPE geomembrane liner in the tank ensures that the oil stays safely contained, even in the match of minor structural defects in the tank itself.

Similarly, in giant - scale water storage reservoirs used in the oil and fuel enterprise for a range of functions like cooling or system water, HDPE geomembranes act as dependable important containment. They stop water from leaking into the surrounding soil, which ought to motive floor subsidence or have an effect on the exceptional of close by water sources. The excessive impermeability of the HDPE geomembrane makes it an perfect desire for these applications. By imparting an superb most important containment solution, HDPE geomembranes make contributions extensively to the protected and environment friendly operation of oil and gasoline facilities.

Secondary Spill Protection

Despite the high-quality efforts in important containment, there is usually a danger of leakage due to unexpected situations such as gear failure, herbal disasters, or human error. This is the place secondary spill safety structures come in, and HDPE geomembranes are imperative factors of these systems.

Secondary spill safety structures are designed to seize any spills or leaks that show up from the essential containment. HDPE geomembranes are typically used as liners in containment berms, sumps, and drip pans. For instance, in a refinery, if an oil storage tank had been to enhance a leak, the HDPE - lined containment berm surrounding the tank would forestall the oil from spreading further. The impermeable geomembrane liner in the berm traps the spilled oil, permitting for secure series and suitable disposal.

In addition, in areas the place pipelines are installed, HDPE geomembranes can be used to create a secondary containment layer. This layer catches any oil or gasoline that may also leak from the pipeline, stopping it from achieving the soil and groundwater. By performing as a backup protection, HDPE geomembranes in secondary spill safety systems assist to reduce the environmental have an impact on of doable spills. They furnish an more layer of security, making sure that the penalties of a fundamental containment failure are mitigated, and the integrity of the surrounding surroundings is preserved.

Installation and Maintenance

Installation Process

The applicable set up of HDPE geomembranes is imperative for making sure their effectiveness in containment and secondary spill protection. The set up system usually starts offevolved with thorough web site preparation. This includes clearing the location of any debris, sharp objects, and irregularities. A clean and secure base is necessary to forestall punctures or injury to the HDPE geomembrane at some point of and after installation. For example, in the set up of an HDPE - lined containment berm round an oil storage tank, the floor have to be leveled and compacted to grant a stable basis for the geomembrane.

Once the website online is prepared, the HDPE geomembrane is cautiously unrolled and laid out. Special interest is paid to make certain that the geomembrane is placed efficiently and covers the complete location that requires protection. The sheets of the HDPE geomembrane are then joined together via a welding process. Welding is a fundamental step as it creates a non-stop and impermeable barrier. There are extraordinary welding techniques available, such as extrusion welding and warm wedge welding.

In extrusion welding, a bead of molten HDPE fabric is extruded alongside the seam between two sheets of the geomembrane, fusing them together. Hot wedge welding, on the different hand, makes use of a heated wedge to soften the edges of the geomembrane sheets, and then strain is utilized to bond them. Skilled operators are required to function the welding manner to make certain excessive - pleasant welds. After welding, the seams are commonly examined for integrity the use of strategies like vacuum checking out or air strain testing. This helps to discover any manageable leaks or susceptible factors in the welds, which can then be repaired earlier than the gadget is put into use. Overall, the right set up of the hdpe geomembrane, from web page instruction to welding and seam testing, is quintessential for its lengthy - time period overall performance in oil and fuel containment systems.

Maintenance Considerations

To make sure the lengthy - time period effectiveness of HDPE geomembranes in oil and fuel applications, everyday renovation is essential. Regular inspections must be carried out to test for any symptoms of injury or wear. This consists of searching for punctures, tears, or symptoms of chemical degradation. For example, in an vicinity the place HDPE geomembranes are used to line pipelines, visible inspections must be carried out periodically to discover any seen symptoms of damage.

If small punctures or tears are detected in the geomembrane material, they ought to be repaired promptly. Minor damages can frequently be repaired the usage of patch kits. The broken region is first cleaned and dried, and then a patch of HDPE geomembrane, barely large than the broken area, is welded or glued onto the broken spot. This helps to keep the integrity of the geomembrane and stop similarly leakage.

It's additionally essential to defend the HDPE geomembranes from immoderate UV publicity if they are used in out of doors applications. Over time, extended publicity to daylight can motive the geomembrane to degrade. Using defensive covers or coatings can assist to lengthen the lifespan of the geomembrane. Additionally, any gear or equipment working in the neighborhood of the HDPE geomembranes need to be cautiously monitored to forestall unintentional damage. By following these upkeep considerations, the overall performance of the HDPE geomembranes can be maintained over the lengthy term, making sure endured safety in oil and fuel containment and secondary spill safety systems.

Comparing with Other Geomembrane Materials

Performance Comparison

When thinking about geomembrane substances for the oil and gasoline industry, HDPE geomembranes stand out in phrases of performance. Compared to different frequent geomembrane substances like Low - Density Polyethylene (LDPE) and Polyvinyl Chloride (PVC), HDPE gives countless awesome advantages.

LDPE geomembranes, for example, have a decrease density and a greater branched molecular shape than HDPE. This effects in a fabric that is extra bendy however much less robust and much less impermeable. In the oil and gasoline context, the place the capacity to face up to excessive - stress elements and stop leakage is crucial, HDPE's excessive impermeability makes it a a ways most effective choice. LDPE may also be extra susceptible to punctures and tears, particularly when uncovered to the mechanical stresses frequently current in oil and gasoline facilities, such as these from heavy tools motion or floor settlement.

PVC geomembranes additionally have their boundaries when in contrast to HDPE. While PVC is distinctly cheaper and has some chemical resistance, it is now not as chemically steady as HDPE in the lengthy - time period when uncovered to the complicated chemical combinations observed in the oil and gasoline industry. PVC can degrade over time when in contact with positive chemical compounds current in oil and gas, which can compromise its integrity as an impermeable geomembrane liner. Additionally, PVC may additionally emit dangerous components when it degrades or is uncovered to excessive temperatures, posing an environmental risk. HDPE, on the different hand, keeps its chemical steadiness and does no longer launch such unsafe via - products, making it a greater dependable choice for lengthy - time period containment and spill safety in oil and gasoline operations. Overall, the special aggregate of excessive strength, brilliant impermeability, and chemical balance makes the hdpe geomembrane a pinnacle - performing desire in the oil and gasoline enterprise in contrast to different frequent geomembrane materials.

Cost - Effectiveness

Cost - effectiveness is a critical component in any industrial choice - making process, and HDPE geomembranes provide considerable blessings in this regard. Although the preliminary buy fee of HDPE geomembranes can also be barely greater than some different geomembrane substances like PVC, when thinking about the lengthy - time period perspective, HDPE proves to be greater fee - effective.

HDPE geomembranes are extraordinarily durable. Their resistance to environmental factors, chemical degradation, and mechanical stress potential that they have a lengthy lifespan. For example, in an oil storage facility, an HDPE - lined containment gadget can remaining for many years barring enormous degradation or the want for foremost repairs. This lengthy - time period sturdiness reduces the want for normal replacements, saving each time and cash in the lengthy run. In contrast, much less long lasting substances may also want to be changed greater often, incurring extra fees for materials, labor, and viable manufacturing disruptions at some point of the substitute process.

Moreover, the low protection necessities of HDPE geomembranes make contributions to their value - effectiveness. As cited earlier, movements inspections and minor repairs are fairly simple and inexpensive. There is no want for complicated and luxurious preservation procedures, in contrast to some different substances that may additionally require specialised redress or normal monitoring to make certain their endured functionality. The geomembrane material's potential to hold its overall performance with minimal renovation efforts makes it an economically conceivable alternative for oil and fuel businesses looking to guard their belongings whilst preserving expenses beneath control. Overall, when factoring in sturdiness and preservation fees over the lengthy - term, HDPE geomembranes provide a favorable fee - advantage ratio, making them a sensible funding for containment and secondary spill safety in the oil and gasoline industry.

Conclusion: The Continued Significance

In conclusion, HDPE geomembranes have end up an vital aspect in the oil and gasoline industry. Their excessive impermeability, chemical stability, and sturdiness make them best for each main containment and secondary spill protection. By correctly stopping the leakage of oil, gas, and different detrimental substances, HDPE geomembranes play a imperative function in safeguarding the environment, defending human health, and decreasing the monetary dangers related with plausible spills.

The actual - world case research have confirmed the sensible effectiveness of HDPE geomembranes in a number oil and gasoline operations. From on - shore storage services to off - shore platforms, these impermeable geomembrane liners have established their capacity to face up to difficult prerequisites and forestall environmental disasters.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province