Key Factors to Consider When Choosing HDPE Geomembrana Thickness for Your Project

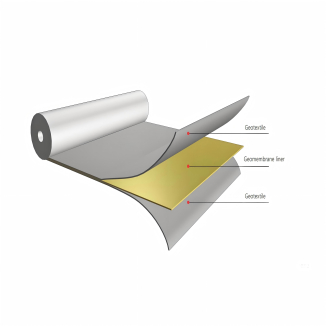

HDPE geomembrana—also known as HDPE geomembrane—is a indispensable barrier for tasks like landfill liners, pond liners, and wastewater containment. Its thickness immediately shapes durability, leak resistance, and long-term value: too thin, and it’s susceptible to punctures; too thick, and it raises cloth and set up costs. Choosing the proper thickness relies upon on project-specific wants that stability protection, budget, and environmental demands. Below, we define 4 key elements to information your hdpe geomembrana thickness selection, making sure your mission is tightly closed and cost-effective.

1. Project Application: Align Thickness with Usage Demands

Every undertaking exposes hdpe geomembrana to special stressors, so thickness should in shape the application’s core needs. High-risk, heavy-stress tasks require thicker material, whilst low-risk makes use of can choose for thinner, greater bendy options. For landfills and hazardous waste containment—projects with heavy tools (bulldozers, compactors), sharp debris, and chemical leachate—HDPE geomembrane thickness have to be 1.5 mm–2.0 mm (60–80 mils). A two mm hdpe geomembrana can deal with 10+ ft of compacted waste except tearing, whereas a thinner 0.75 mm liner would fail quickly.

For water containment (ponds, reservoirs), the place chemical chance is low however UV publicity and minor affects (floating debris, tree roots) are common, hdpe geomembrana thickness levels from 0.75 mm–1.2 mm (30–48 mils). A 1.0 mm geomembrane works properly for farm ponds: it resists punctures from roots or animals and stays bendy adequate to contour to uneven terrain. Canals and irrigation systems, which want flexibility for sloped aspects plus resistance to water float erosion, use 0.5 mm–1.0 mm (20–40 mils) hdpe geomembrana—a 0.75 mm choice bends over canal edges except cracking and withstands put on from transferring water.

Start with the aid of defining your project’s purpose: high-risk makes use of demand thicker hdpe geomembrana, whilst low-risk, flexible-need tasks can use thinner material.

2. Environmental Stressors: Protect Against Weather and Chemicals

Hdpe geomembrana faces steady environmental wear, and thickness ought to account for UV radiation, temperature extremes, and chemical contact to keep away from untimely failure. For outside initiatives (ponds, canals) with extended solar exposure, thinner HDPE geomembrane (under 0.75 mm) breaks down fast—becoming brittle and cracking in 5–7 years. A 1.0 mm+ hdpe geomembrana has greater polymer mass to take in UV rays, extending its lifespan to 20+ years; in sunny climates (e.g., the Southwest U.S.), decide for at least 1.2 mm to counter severe UV.

Temperature extremes additionally matter: in bloodless climates (-20°C or lower), thin geomembrane (under 0.5 mm) turns inflexible and cracks when frozen, whilst thicker fabric (1.0 mm+) retains flexibility to manage freeze-thaw cycles. In warm climates, thicker hdpe geomembrana resists softening, stopping it from sticking to tools or stretching below its very own weight. For tasks with chemical substances (fertilizer runoff, landfill leachate), thicker cloth gives higher protection: whilst HDPE is naturally chemical-resistant, thin geomembrane has fewer layers to block permeation. A 1.5 mm hdpe geomembrana acts as a better barrier, decreasing the chance of leaks that contaminate soil or groundwater.

Assess your project’s surroundings first: harsh UV, severe temperatures, or chemical compounds all name for thicker hdpe geomembrana.

3. Installation and Site Conditions: Account for Terrain and Handling

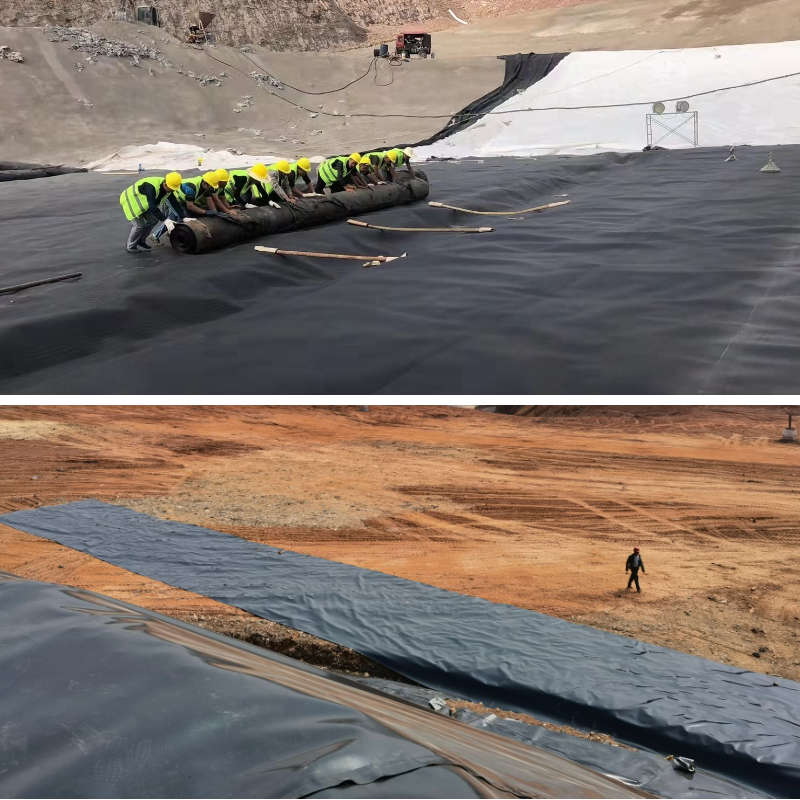

Site complexity—uneven terrain, sharp objects, heavy equipment—impacts how thick your hdpe geomembrana needs to be. Thinner fabric is prone to injury for the duration of installation, whilst thicker selections stand up to hard coping with and difficult sites. For uneven or rocky terrain (with rocks, tree roots, or steep slopes), use 1.0 mm–1.5 mm HDPE geomembrane. Thin fabric (0.5 mm–0.75 mm) can be punctured via small rocks when stretched over uneven ground—for example, a 0.75 mm geomembrane on a rocky pond mattress may additionally tear when employees stroll on it. A 1.2 mm hdpe geomembrana bridges small rocks besides puncturing, reducing set up risks.

If set up makes use of heavy equipment (cranes for massive rolls, compactors for soil pressing), thicker hdpe geomembrana (1.5 mm+) is essential. Thin cloth can tear from gear tires or raise in wind, whilst thicker choices remain stable—landfill projects, the place bulldozers cross waste over liners, count on two mm geomembrane for tire harm resistance. Seam power additionally relies upon on thickness: thinner hdpe geomembrana (under 0.75 mm) has narrow, vulnerable seams that separate easily, whilst 1.0 mm+ fabric approves wider, extra long lasting heat-welded or glued seams—critical for leak prevention.

Evaluate your site’s challenges: rocky terrain, heavy equipment, or complicated seams all require thicker hdpe geomembrana for a smooth, damage-free installation.

4. Regulatory Standards and Long-Term Warranties

Local rules and producer warranties frequently set minimum hdpe geomembrana thicknesses, reflecting enterprise security and sturdiness standards. Ignoring these can lead to fines, challenge delays, or failed inspections. Most areas have strict rules: the U.S. EPA mandates 1.5 mm minimum HDPE geomembrane for landfill liners to forestall leachate contamination, whilst the EU requires at least 0.75 mm hdpe geomembrana for water containment. Always test nearby constructing codes or environmental agencies—thickness under necessities effects in non-compliance.

Warranties additionally information thickness choices: thicker hdpe geomembrana comes with longer coverage. A 0.75 mm geomembrane may have a 5–10 12 months warranty, whilst 1.5 mm+ alternatives provide 15–25 years. Warranties sign producer confidence—short warranties for skinny cloth suggest greater failure risk. For long-term tasks (e.g., a 20-year reservoir), thicker hdpe geomembrana with an prolonged guarantee avoids sudden substitute costs.

Never pass regulatory checks: compliance ensures legality and safety, whilst warranties defend your investment. Thicker geomembrane not solely meets requirements however additionally affords lasting peace of mind.

Final Tips for Choosing HDPE Geomembrana Thickness

Avoid overspending on pointless thickness or reducing corners with too-thin material—balance is key. Consult hdpe geomembrana manufacturers with your assignment important points (application, website conditions, regulations); they’ll endorse thickness primarily based on product specs and real-world performance. Request samples to take a look at flexibility (bend to mimic web site contours) and puncture resistance (press a sharp object into the material) to gauge durability.

By focusing on assignment application, environmental stressors, web page conditions, and regulations, you’ll pick out the right hdpe geomembrana thickness—one that protects your project, meets standards, and stays inside budget. Whether lining a pond, landfill, or canal, the correct geomembrane thickness is the basis of a long-lasting, leak-free barrier.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province