Key Dewatering Bag Specifications: Tensile Strength, UV Resistance, and Porosity

Dewatering is a vital step in waste management, construction, and environmental remediation, and the success of this technique hinges on selecting the proper equipment. Dewatering Bags and Dewatering Geotube structures are amongst the most dependable solutions, however their overall performance is described by using three core specifications: tensile strength, UV resistance, and porosity. These elements decide how properly the baggage deal with heavy loads, stand up to outside conditions, and separate solids from liquids—directly impacting task efficiency, cost, and durability. This information dives deep into these key specifications, explaining why they matter, how they differ across Geotube Material Specifications, and how to pick the proper Dewatering Bags for your unique needs. By perception these crucial traits, you can make certain your dewatering undertaking runs easily and offers long-lasting results.

Understanding Dewatering Bags and Dewatering Geotube Systems

Dewatering Bags and Dewatering Geotubes are large, permeable geotextile containers designed to filter and dewater slurries (mixtures of solids and liquids). While Dewatering Bags are usually smaller and used for batch processing (e.g., in development websites or agricultural waste management), Dewatering Geotubes are larger, continuous tubes best for high-volume functions like mining tailings or municipal wastewater treatment. Both count on the identical core Geotube Material Specifications to feature effectively, with tensile strength, UV resistance, and porosity being the most influential factors.

The dewatering procedure works via pumping slurry into the geotextile container. The fabric’s porosity lets in water to drain out, leaving at the back of a focused strong cake. The effectivity of this process—and the sturdiness of the equipment—depends totally on how properly the material’s specs align with the project’s demands. For example, a mining undertaking with heavy, abrasive slurry requires excessive tensile strength, whilst a coastal dewatering web page desires remarkable UV resistance to stand up to consistent solar exposure.

Tensile Strength: The Backbone of Dewatering Bag Durability

Tensile electricity refers to a material’s capability to withstand breaking beneath anxiety (pulling force). For Dewatering Bags and Dewatering Geotubes, this specification is non-negotiable—slurries exert extensive strain on the cloth as they fill the container, and vulnerable cloth will tear or rupture, main to mission delays and waste spillage.

Why Tensile Strength Matters

When a Dewatering Bag is crammed with slurry, the weight of the liquid and solids stretches the fabric. High tensile energy ensures the bag continues its structure and structural integrity, even when utterly loaded. This is mainly quintessential for Dewatering Geotubes, which can be thousands of toes lengthy and preserve heaps of cubic yards of material—any weak point in the material should end result in catastrophic failure.

Tensile electricity additionally affects dealing with and installation. Bags with low tensile electricity can also tear in the course of transport or when being moved with heavy equipment, whilst high-strength selections can face up to tough dealing with barring damage. Additionally, throughout dewatering, the stable cake interior the bag shrinks as water drains, and the fabric’s tensile energy permits it to modify to this shrinkage besides cracking.

Geotube Material Specifications for Tensile Strength

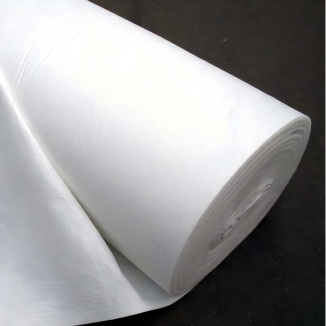

Geotube Material Specifications for tensile energy fluctuate via application. Most Dewatering Bags are made from woven polypropylene (PP) or polyethylene (PE) fabrics, which provide terrific tensile strength. Woven fabric are desired over non-woven due to the fact their interlocked fibers distribute anxiety evenly throughout the material. Manufacturers frequently specify tensile electricity in two directions: computing device course (along the size of the roll) and cross-machine route (width of the roll), making sure the bag is sturdy in all orientations.

UV Resistance: Protecting Dewatering Bags from Sun Damage

Most dewatering tasks take region outdoors, exposing Dewatering Bags and Dewatering Geotubes to steady UV radiation. UV rays spoil down polymer bonds over time, inflicting the cloth to grow to be brittle, fade, and lose strength. UV resistance is consequently a imperative specification for any dewatering machine supposed for outside use.

The Impact of UV Degradation

Without enough UV resistance, Dewatering Bags can degrade in as little as a few months, relying on the climate. Brittle material is susceptible to tearing, even beneath mild loads, and can also no longer entire the dewatering method earlier than failing. This no longer solely will increase mission fees (due to alternative bags) however additionally creates environmental risks—spilled slurry can contaminate soil or waterways.

UV resistance is specially essential in sunny, arid areas or coastal areas the place UV depth is high. In these environments, a Dewatering Geotube except UV safety may also want to be changed each and every 6–12 months, whilst UV-stabilized alternatives can closing 3–5 years or more.

Enhancing UV Resistance in Dewatering Solutions

Manufacturers enhance UV resistance through including stabilizers to the geotextile cloth all through production. These stabilizers (often hindered amine mild stabilizers, or HALS) take in UV rays and forestall them from breaking down the polymer structure. Geotube Material Specifications normally encompass facts on UV stabilization, with some fabric rated for up to 10 years of out of doors exposure.

For brief initiatives (e.g., 6 months or less), UV resistance may additionally be much less critical, however for long-term dewatering or storage, it’s essential. Some Dewatering Bags additionally come with a protecting coating that in addition shields the material from UV damage, making them appropriate for severe solar conditions.

Porosity: Balancing Filtration and Solids Retention

Porosity refers to the wide variety and dimension of pores in the geotextile fabric, which determines how rapidly water drains out of the Dewatering Bag and how nicely it retains solids. Finding the right stability of porosity is key—too porous, and solids will break out with the water; too dense, and dewatering will be sluggish and inefficient.

The Role of Porosity in Dewatering Efficiency

High porosity permits water to drain quickly, decreasing the time wanted to shape a strong cake. This is really useful for tasks with tight deadlines, as it speeds up the dewatering process. However, if the pores are too large, nice solids (e.g., silt or clay) will ignore via the fabric, contaminating the discharged water and requiring extra filtration.

Low porosity, on the different hand, retains extra solids however slows drainage. This is appropriate for slurries with exceptional particles, as it ensures easy effluent, however it might also prolong the venture timeline. The best porosity relies upon on the kind of slurry being dewatered—for example, a slurry with coarse sand can use a extra porous fabric, whilst a slurry with fantastic mud wishes a denser fabric.

Matching Porosity to Project Needs

Geotube Material Specifications for porosity are frequently given as a drift price (e.g., gallons per minute per rectangular foot) or pore measurement (in microns). Dewatering Bags for development sludge (which has a combine of coarse and exceptional particles) normally use a medium-porosity fabric, whilst Dewatering Geotubes for mining tailings (which may additionally have very best particles) use a low-porosity, high-retention fabric.

Manufacturers additionally provide customized porosity options, permitting you to tailor the Dewatering Bags to your unique slurry. This customization ensures most reliable dewatering efficiency—fast ample to meet deadlines, however thorough sufficient to produce easy water and a dense strong cake.

How to Select Dewatering Bags Based on Key Specifications

To select the right Dewatering Bags or Dewatering Geotubes, consider your project’s special wishes towards the three key specifications:

Assess Tensile Strength Needs: Consider the extent and weight of the slurry. Heavy, dense slurries (e.g., mining waste) require excessive tensile power fabrics, whilst lighter slurries (e.g., agricultural manure) can use medium-strength options.

Evaluate UV Exposure: Determine the task period and climate. Long-term out of doors tasks in sunny areas want UV-stabilized fabrics, whilst temporary or indoor tasks can use wellknown materials.

Analyze Slurry Particle Size: Test the slurry to become aware of particle dimension distribution. Coarse particles want excessive porosity; nice particles want low porosity to continue solids.

Conclusion: The Right Specifications for Successful Dewatering

Tensile strength, UV resistance, and porosity are the basis of nice Dewatering Bags and Dewatering Geotubes. By appreciation these Geotube Material Specifications and matching them to your project’s demands, you can make sure environment friendly dewatering, decrease costs, and limit environmental risks.

Whether you’re managing building waste, mining tailings, or agricultural effluent, investing in Dewatering Bags with the proper specs is critical. Don’t settle for one-size-fits-all solutions—work with producers to pick or personalize fabrics that align with your slurry type, challenge timeline, and environmental conditions. With the proper dewatering system, you’ll streamline operations, produce smooth water and reusable solids, and acquire long-term challenge success.

Contact Us

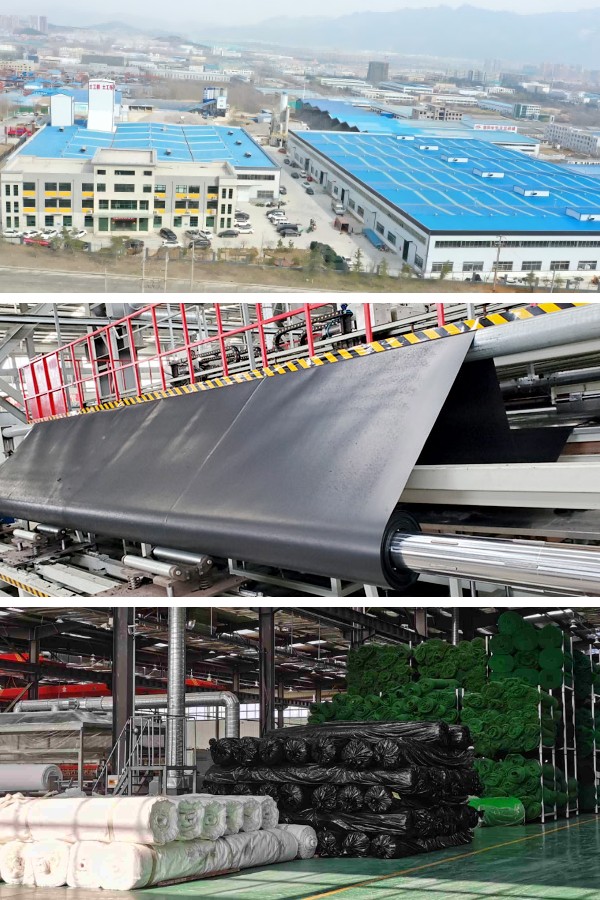

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province