The Importance of Woven Geotextile in Railroad Track Bed Construction

Introduction: The Unseen Foundation of Modern Railroads

The vast weight and dynamic forces of a passing teach are eventually transferred down thru the rails, ties, and into the music bed—the very basis of the complete railroad system. A stable, well-designed song mattress is non-negotiable for safety, speed, and operational efficiency. For decades, the main venture has been the migration of first-class subgrade soil particles up into the smooth ballast layer, a procedure acknowledged as subgrade intrusion, which leads to music instability, bad drainage, and costly, prevalent maintenance. The engineered answer to this age-old hassle is the strategic use of woven geotextiles. This particular geo material fabric acts as a strong separator, making sure the integrity of the music mattress for decades. This article explores the vital characteristic of woven geotextile mesh in developing a resilient and long-lasting railroad foundation.

The Problem: Track Bed Degradation and Subgrade Failure

Without protection, the repeated, high-impact loading from trains motives the coarse combination ballast to be pushed down into the softer subgrade. Simultaneously, water infiltration can pump best silt and clay particles up into the ballast. This two-way migration has extreme consequences:

Loss of Structural Integrity: The intermixing of soil and ballast creates a weakened base that can't suitable help the track. This leads to uneven agreement and song misalignment.

Impaired Drainage: The contaminated ballast loses its potential to drain water effectively. Water will become trapped in the tune bed, main to saturated subgrades, decreased shear strength, and accelerated frost heave in bloodless climates.

Increased Maintenance Cycles: To repair suitable tune geometry and drainage, railway operators should regularly agenda high priced undercutting and ballast substitute operations, inflicting tremendous downtime.

The Solution: Woven Geotextile as a Strategic Separator

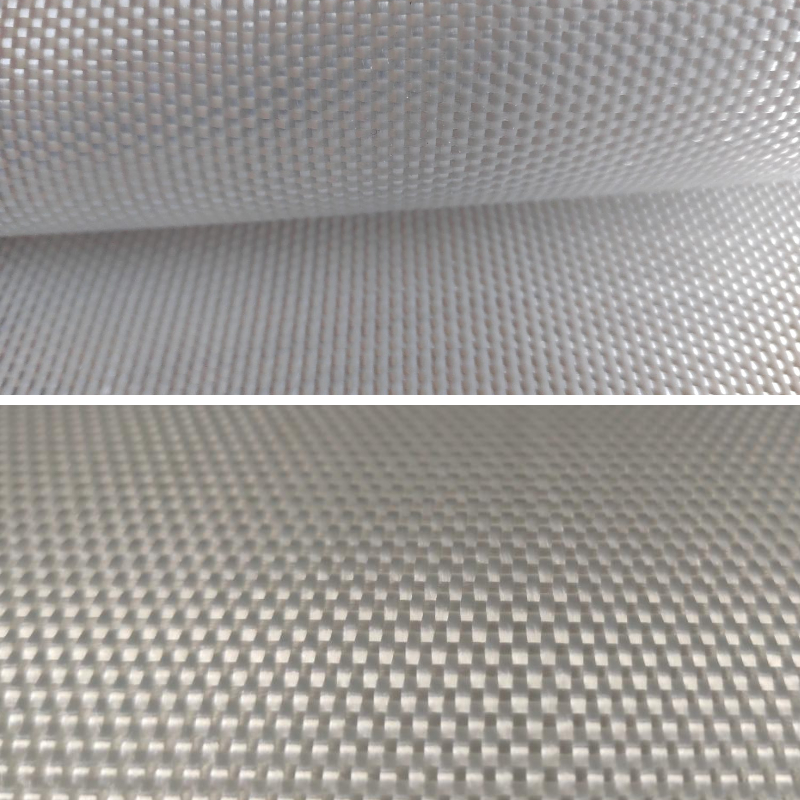

A woven geotextile is a high-strength geo cloth cloth manufactured by using interlacing artificial tapes or filaments. When mounted between the subgrade and the ballast layer, it creates a permanent, durable separation membrane. Its essential position is to forestall the intermixing of numerous substances whilst permitting for indispensable water passage, functioning as each a strong separator and an high quality filtration geotextile.

Key Functions of Woven Geotextile in Track Beds

1. Robust Separation for Long-Term Stability

The excessive tensile energy and puncture resistance of a woven geotextile mesh forestall the ballast stone from penetrating the smooth subgrade. By preserving a awesome boundary between the two layers, the geotextile ensures that the ballast layer retains its thickness and structural properties. This separation is the cornerstone of a secure track, distributing educate hundreds evenly and minimizing differential settlement. The long lasting nature of this geo cloth cloth ensures that this separation is maintained during the graph lifestyles of the railway.

2. Filtration and Drainage Preservation

While stopping soil intrusion, the cautiously engineered pore shape of a woven geotextile lets in water to glide freely from the ballast into the subsoil and vice versa, except washing out best particles. This feature is necessary for a high-performance filtration geotextile. By stopping the ballast from turning into clogged with fines, the geotextile ensures the music mattress stays well-drained, stopping water-related softening of the subgrade and defending the tune from freeze-thaw cycles.

3. Reinforcement and Confinement

In areas with very tender subgrades, the excessive tensile modulus of a woven geotextile mesh presents a measurable reinforcing effect. It helps to confine the subgrade soil and distributes the tremendous wheel hundreds over a wider area, growing the ordinary bearing potential of the basis and decreasing the required ballast thickness.

Why Woven Geotextile is Superior for Railroad Applications

The precise residences of woven geotextiles make them uniquely applicable for the harsh needs of a railroad environment.

High Tensile Strength and Low Elongation: Woven geotextiles showcase incredible resistance to stretching underneath load. This dimensional balance is critical underneath the dynamic stresses of instruct traffic, stopping rutting and deformation.

Excellent Survivability: The rugged development of a woven geo material cloth offers excessive puncture and abrasion resistance, making sure it is no longer broken at some point of the set up of sharp, heavy ballast stone or from long-term cyclic loading.

Optimal Filtration Characteristics: The slit-film weaving system creates specific pore openings that are perfect for soil retention barring compromising water flow, satisfying the position of an wonderful filtration geotextile.

Installation Best Practices

For a woven geotextile to operate as intended, right set up is paramount. The subgrade need to be graded to the layout profile and compacted. The geotextile rolls are then deployed perpendicular to the tune centerline, with adequate facet and give up overlaps (typically 12 to 24 inches) as per task specifications. The geotextile mesh should be positioned except immoderate anxiety or wrinkles and straight away included with ballast to forestall UV degradation and displacement. The preliminary elevate of ballast must be positioned cautiously to keep away from adverse the fabric.

Conclusion: Building a Smoother, More Resilient Future for Rail

The integration of a woven geotextile is a small funding with an outsized return in the existence cycle of a railroad. By functioning as a high-strength separator and a dependable filtration geotextile, this engineered geo fabric cloth without delay addresses the root reasons of tune mattress failure. It is a foundational technological know-how that permits greater axle loads, quicker speeds, and extensively prolonged protection cycles. For any new railway building or tune rehabilitation project, specifying a woven geotextile mesh is no longer simply a nice practice—it is an vital engineering choice for constructing a safer, greater efficient, and greater long lasting rail network.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province