Marine and Dredging Applications: Deploying Geotube for Contaminated Sediments.

Introduction: The Critical Challenge of Contaminated Sediments

The legacy of industrial hobby regularly settles at the bottom of our waterways—in the structure of contaminated sediments. Dredging to put off these sediments, which can be encumbered with heavy metals, hydrocarbons, and extraordinary pollutants, is a crucial step for environmental remediation, port expansion, and navigation channel maintenance. However, the challenge starts offevolved the 2nd the sediment is eradicated from the water: how do you efficiently, safely, and cost-effectively manipulate this hazardous slurry? Traditional methods like restricted disposal services can be prohibitively excessive priced and land-intensive. This is the location most useful dewatering and containment technologies, specially geosynthetic tubes, furnish a transformative solution. This article explores how these engineered containers, regularly referred to in constructions like the sludge bag dewatering system, are revolutionizing the managing of contaminated elements in marine and dredging projects.

The Problem with Wet Sediment: Why Dewatering is Non-Negotiable

Contaminated sediment dredged from harbors, rivers, and industrial canals is generally 70-90% water with the aid of skill of volume. Transporting and disposing of this giant extent of water is now no longer entirely logistically and financially unsustainable alternatively moreover environmentally risky. The immoderate water content material cloth creates a liquid, cell waste that can besides troubles leach contaminants. Effective dewatering is subsequently the most crucial step in the remediation process. It dramatically reduces the total extent of waste, transforming a liquid coping with hassle into a robust administration one. This volume cut price is the major driver for the use of specialised dewatering baggage for sludge, as they barring prolong intention this core issue, major to massive monetary financial savings in transportation and disposal costs.

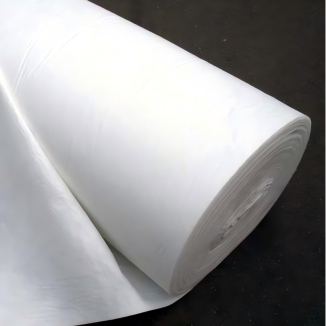

Geosynthetic Tubes: The Engineered Solution for Containment and Dewatering

Geosynthetic tubes are high-strength, permeable containers manufactured from engineered polypropylene geotextiles. Designed normally for dewatering applications, these tubes act as every a dewatering press and a tightly closed containment vessel. The fabric is engineered with unique pore sizes that allow convenient water to spoil out at the same time as retaining exceptional steady particles and contaminants within. When deployed as area of a whole sludge bag dewatering system, they grant a closed-loop technique that minimizes environmental publicity and worker contact with the contaminated material. Their functionality to be deployed besides extend at the venture site—on a barge, a committed dewatering pad, or interior a restrained area—makes them in particular versatile for a ways off or space-constrained marine projects.

The Dewatering Process: From Slurry to Stable Solids

The operational approach for the use of geosynthetic tubes is a systematic and surroundings pleasant cycle that ensures most dewatering and containment.

Site Preparation and Tube Deployment: A dedicated dewatering area is geared up with a defending liner. The empty geosynthetic tubes are positioned on this liner, in many instances in a couple of rows to deal with massive volumes.

Conditioning and Pumping: The dredged sediment slurry is first blended with a flocculant polymer. This indispensable step reasons the first-rate particles to clump mutually into massive flocks, which dewater more effectively and are a lot much less per chance to blind the pores of the tube fabric.

Filling and Filtration: The conditioned slurry is pumped into the tubes the utilization of high-capacity pumps. As the tubes fill, water starts offevolved offevolved to exude via the fabric pores, a approach accelerated via the gradual make bigger in indoors pressure. The contained solids shape a stable, contained cake.

Consolidation and Curing: Once filling is complete, the tubes are left to consolidate further. Over a period of weeks, greater water drains out, and the solids proceed to densify. The ultimate quit end result is a extensively reduced extent of dewatered, consistent material that is organized for subsequent handling, on-site capping, or transport to a licensed disposal facility.

Key Advantages in Marine and Dredging Applications

The use of a sludge bag dewatering system built spherical geosynthetic tubes offers a multitude of blessings over regular methods.

Superior Containment and Environmental Safety: The tubes furnish a bodily barrier between the contaminated sediments and the surrounding environment. This sealed device prevents the re-release of air pollution into the air or water, defending ecosystems and making positive regulatory compliance.

Significant Volume and Cost Reduction: By disposing of the water, these buildings can restriction the whole extent of dredged material by way of way of 50-90%. This interprets at as soon as into giant monetary financial savings on transportation, disposal fees, and the footprint required for on-site storage.

Mobility and Flexibility: Unlike regular treatment plants, a sludge bag dewatering device is relatively mobile. The tools and tubes can be deployed besides prolong on a barge or at the shoreline, casting off the favor for long-distance pumping of the heavy slurry and enabling remedy at the source.

Adaptability to Various Sediments: The system is satisfactory at some point of a giant differ of sediment types, from fine-grained clays and silts to herbal peats. By adjusting the polymer form and dosage, the approach can be optimized for even the most challenging, fine-grained contaminated materials.

Proven Applications in the Marine Sector

This technological information has been efficiently deployed in a vary of complex scenarios:

Harbor and Navigation Channel Remediation: Dewatering contaminated sediments dredged to keep shipping lanes.

Industrial Canal Cleanup: Managing carefully polluted sediments from legacy industrial sites.

Contaminated Lagoon and Pond Restoration: Remediating settled wastes in enclosed water bodies, the vicinity dewatering baggage for sludge furnish an all-in-one solution.

Capping Preparedness: Dewatering sediments to a consistent consistency that is splendid for being safely capped in a restrained aquatic disposal site.

Conclusion: A Sustainable Path Forward for Marine Remediation

Managing contaminated sediments is one of the most substantial challenges in marine infrastructure and environmental restoration. The adoption of geosynthetic tubes interior a well-designed sludge bag dewatering computing device represents a best-in-class approach. It can furnish a high quality combination of environmental protection, dramatic fee savings, and operational flexibility. By transforming unstable, high-risk slurry into manageable, dewatered solids, this science offers a in charge and sustainable course forward, turning the tide on sediment sickness and paving the way for cleaner, safer waterways. For any upcoming dredging mission involving contaminated materials, specifying this engineered dewatering reply is a strategic choice for success.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province