How to Stabilize Soft Subgrade with Geocell for Road and Pavement Construction

Building long lasting roads and pavements on soft, unstable floor is a great mission for engineers and development professionals. Weak subgrades, regularly composed of clay, silt, or unfastened sand, are susceptible to contract and deformation below load, main to untimely pavement failure. Fortunately, geocell technological know-how gives a sturdy and reasonably priced solution. This complete information explains how to stabilize gentle subgrades the usage of geocell for street construction, making sure long-lasting and dependable infrastructure.

Understanding the Problem: The Risks of Soft Subgrade

Before delving into the solution, it is quintessential to recognize why gentle subgrades are problematic. A subgrade is the native soil upon which the pavement shape is built. When this soil is soft, it lacks the essential electricity and stiffness to aid visitors loads. This effects in problems like:

Rutting and Differential Settlement: The pavement floor develops grooves and uneven areas as the tender soil underneath it shifts and compresses.

Alligator Cracking: The traditional sample of interconnected cracks that sign a failure in the underlying help layers.

Total Pavement Failure: In extreme cases, the complete street shape can collapse, requiring costly and disruptive reconstruction.

Traditional techniques like soil elimination and substitute or the usage of thick layers of mixture are frequently costly, time-consuming, and unsustainable. This is the place the modern software of road development geocell will become a game-changer.

What is a Geocell and How Does It Work?

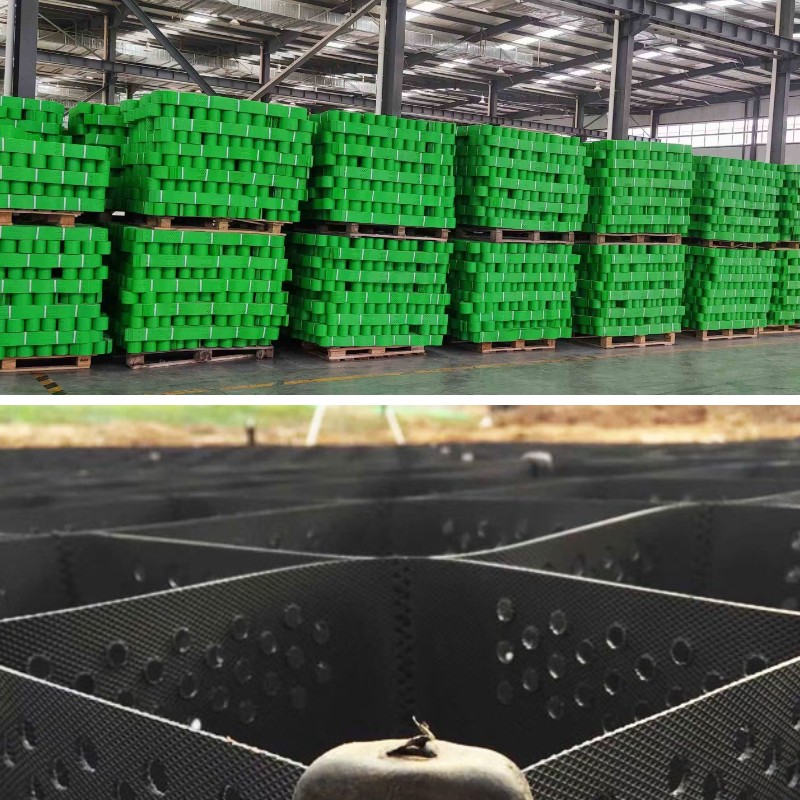

A geocell is a three-dimensional, honeycomb-like shape made from high-density polymer strips welded collectively ultrasonically. When improved on-site, it types a flexible, permeable mattress that is then infilled with soil, sand, or aggregate.

The stabilization mechanism of geocell for avenue construction is primarily based on two key principles:

1. Confinement: The cell pockets confine the infill material, stopping its lateral motion beneath load. This confinement dramatically will increase the stiffness and load-bearing potential of the infill, correctly growing a strong, composite foundation.

2. Load Distribution: The geocell device acts as a semi-rigid slab that distributes the imposed wheel hundreds over a wider location of the susceptible subgrade. This reduces the vertical stress on the gentle soil, stopping immoderate settlement.

By combining confinement and wide-area load distribution, a road development geocell transforms a weak, unstable subgrade into a steady working platform succesful of helping pavement layers.

Step-by-Step Guide to Stabilizing Soft Subgrade with Geocell

Successfully imposing a geocell stabilization mission requires a meticulous approach. Here is a precise step-by-step procedure for the usage of geocell for avenue construction on tender ground.

Step 1: Site Assessment and Subgrade Preparation

The first step is a thorough geotechnical investigation to decide the houses of the tender subgrade, such as its California Bearing Ratio (CBR) and moisture content. The website have to then be prepared:

Clear and Grade: Remove vegetation, debris, and giant stones.

Excavate (if necessary): In extraordinarily smooth conditions, a shallow excavation may additionally be required.

Compact and Level: Compact the present subgrade to create a uniform, degree surface. Proper drainage have to be ensured to stop water accumulation, which can weaken the subgrade further.

Step 2: Geotextile Installation (Optional however Recommended)

Before setting the geocell, it is especially recommended to lay a non-woven geotextile material immediately on the organized subgrade. This cloth serves two integral functions:

Separation: It prevents the best particles of the tender subgrade from mixing with the coarse infill fabric of the geocell, keeping the integrity and drainage potential of the infill.

Filtration: It approves water to ignore via whilst maintaining soil particles, accordingly assisting in consolidation and improving drainage.

Step 3: Geocell Placement and Expansion

Unfold the geocell panels over the geotextile. Stretch the panels utterly to attain their designed depth and telephone size. The improved road building geocell have to structure a continuous, interlocked layer. Anchor pins or stakes are used at the edges and junctions to impenetrable the device in place, stopping motion in the course of the infill process.

Step 4: Infilling the Geocell

This is a crucial section the place the composite basis is created. The preference of infill fabric relies upon on availability and challenge requirements, however it normally includes:

Quality Aggregate: Crushed stone or gravel is the favored desire for high-traffic roads as it offers exceptional shear electricity and drainage.

Sand: Suitable for lighter masses or brief get admission to roads.

Local Soil: In some cases, stabilized neighborhood soil can be used, imparting huge price savings.

The infill is positioned in two stages. First, a shallow layer is unfold and compacted to about one-third of the cellphone depth to furnish a secure base for equipment. The cells are then stuffed to their full height, barely overfilling to create a "cap" that protects the geocell membrane from abrasion.

Step 5: Compaction and Surface Finishing

Compact the infill fabric the use of a vibratory curler or plate compactor. Proper compaction is critical to gain the excessive density and interlock of the infill inside the cells, maximizing the confinement effect. After compaction, the floor is graded to the favored profile, equipped for the subsequent base direction and asphalt or concrete pavement layers.

Key Benefits of Using Geocell for Road Construction

The use of geocell for avenue construction gives a multitude of blessings over common methods:

Superior Load Support: The 3D confinement creates a stiff mattress that substantially reduces deformation underneath static and dynamic loads.

Reduced Aggregate Thickness: By improving the overall performance of the infill, a geocell device can limit the required thickness of the mixture base direction with the aid of up to 50%, main to large value financial savings on substances and transport.

Sustainability: Using much less quarry-based combination and enabling the use of on-site soils reduces the project's carbon footprint and preserves herbal resources.

Construction on Very Soft Soils: Road development geocell is distinctly advantageous on soils with very low CBR values (even beneath 1%), the place common strategies would be unfeasible or prohibitively expensive.

Increased Service Life: By presenting a secure foundation, it minimizes differential contract and rutting, thereby extending the pavement's lifespan and decreasing long-term preservation costs.

Faster Construction: The set up procedure for a geocell is fast and straightforward, accelerating mission timelines.

Conclusion: A Smart Investment for Long-Term Performance

Stabilizing smooth subgrades with geocell is a proven, engineered answer that overcomes the inherent weaknesses of not easy soils. The technological know-how of road development geocell offers an efficient, economical, and sustainable choice to common methods, remodeling susceptible floor into a strong, secure platform. By following the perfect installation steps—from web site practise to infill compaction—you can make sure the success of your street or pavement project, guaranteeing sturdiness and overall performance for years to come. For your subsequent assignment on difficult ground, reflect onconsideration on the effective confinement and load distribution advantages of geocell for street construction as your predominant stabilization strategy.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province