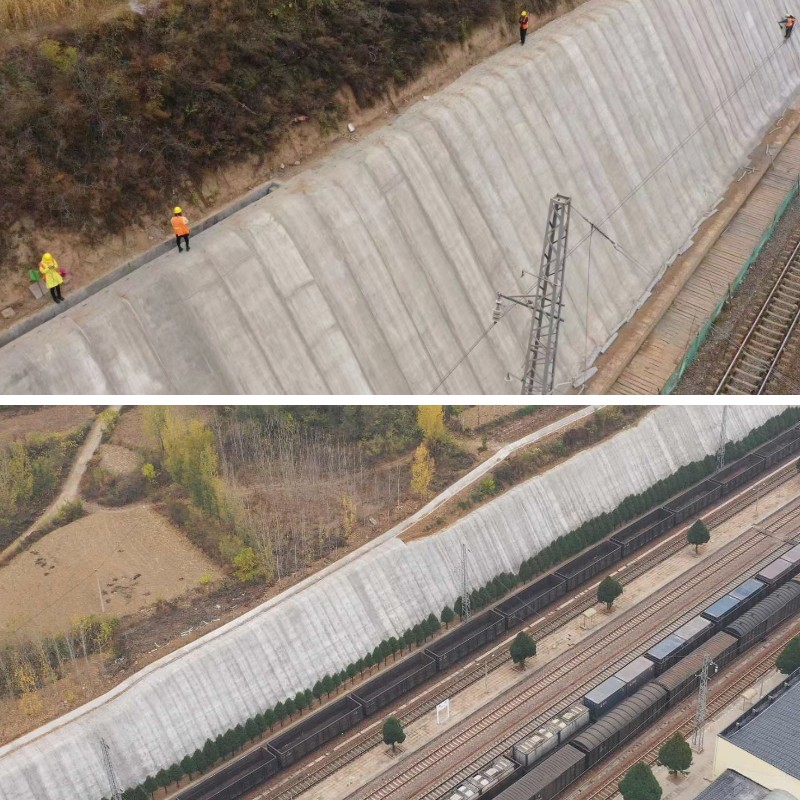

How to Properly Place and Secure a Cement Blanket on Slabs and Foundations

Are you worn-out of the mess, time, and inconsistency of standard concrete pouring and curing methods? Whether you are a contractor, a civil engineer, or a committed DIYer, there is a smarter way to attain durable, resilient concrete surfaces. The innovative answer lies in the cement blanket, a bendy material that hardens on hydration to structure a thin, strong concrete layer. Proper set up is the key to unlocking its full achievable for initiatives ranging from slab safety to complicated culvert lining and erosion manipulate ditch liner material applications. This definitive information will stroll you via each and every crucial step to make certain your mission is a long-lasting success.

Understanding the Cement Blanket Revolution

Before diving into the set up process, it is quintessential to apprehend what you are working with. A cement blanket is a technologically advanced, bendy composite material. It normally consists of a 3-dimensional fiber matrix crammed with a dry, powdered concrete mix. A water-proof membrane on one facet completes the system. When saturated with water, it treatment options to structure a durable, non-erodible concrete layer besides the want for mixing, pouring, or formwork. This makes it an perfect answer for culvert lining and slope stabilization, the place its function as an erosion manage ditch liner material is unmatched. Its versatility and ease of use are remodeling development and restore workflows globally.

Pre-Installation Essentials: Site Preparation is Key

The success of any cement blanket set up hinges on meticulous preparation. Rushing this stage is the most frequent reason of mission failure.

Thoroughly Clean the Substrate

The floor have to be sound, stable, and clean. For current slabs and foundations, do away with all debris, dirt, oil, laitance, and free material. For earthen slopes or culvert lining projects, the intention is to create a smooth, compacted subgrade. Remove vegetation, rocks, and any protruding objects that should puncture the material. A well-prepared subgrade ensures full contact between the cement blanket and the ground, stopping voids and making sure uniform curing.

Profile and Shape the Surface

The cement blanket is bendy however can't bridge massive gaps. Fill any large cracks in concrete or voids in soil with a appropriate compactable fill material. For slopes requiring erosion manage ditch liner material, the floor ought to be graded to a regular slope to facilitate easy water runoff as soon as installed. Proper profiling is non-negotiable for advantageous culvert lining, as it ensures a uniform waft channel.

Gather Your Tools and Materials

Having the whole lot on hand streamlines the process. You will need:The cement blanket itself.

A smooth water supply (a hose with a spray attachment is ideal).

Heavy-duty utility knife or scissors.

Staples, panorama stakes, or specialised fasteners.

A curler (a hand curler or garden roller).

Overlap adhesive (if required for your project).

Step-by-Step Guide to Placement and Securing

This is the core of the process, the place precision and care supply expert results.

Step 1: Unrolling and Positioning the Blanket

Carefully unroll the cement blanket over the organized location with the water-resistant membrane going through down (against the substrate). Avoid dragging the cloth to stop harm or loss of the dry mix. For giant areas or complex shapes like culvert lining, you may additionally want to reduce smaller, greater manageable sections. Always format your design to reduce seams and make sure they run in a course that might not intervene with water go with the flow or structural integrity.

Step 2: Cutting and Custom Fitting

The cement blanket can be effortlessly reduce to suit round corners, protrusions, or curves. Use a sharp utility knife and reduce from the backing aspect for a cleaner edge. When performing culvert lining, precision reducing is integral to make certain the cloth conforms flawlessly to the culvert's indoors shape, growing a seamless protecting layer. For slabs, make sure the blanket extends to the edges barring overhanging unnecessarily.

Step 3: The Critical Securing Phase

Before including any water, you have to routinely tightly closed the blanket. This prevents motion and moving for the duration of the hydration process, which is critical for its overall performance as an erosion manage ditch liner material.

On Soil/Slopes: Use sturdy panorama U-stakes or comparable fasteners. Place them round the perimeter and in a grid sample throughout the field, about 12-18 inches apart. Stakes need to be pushed flush with the floor of the blanket.

On Concrete Slabs: Use concrete nails or a powder-actuated device to impenetrable the blanket at once to the current slab. On vertical or overhead surfaces, a mixture of fasteners and specialised adhesives may also be necessary.

Overlapping Seams: When a couple of rolls are needed, create a minimal 4-inch overlap. Secure each layers of the overlap completely with fasteners. For permanent, watertight seams in culvert lining applications, use the manufacturer-recommended overlap adhesive between the layers earlier than securing.

Step 4: Achieving Perfect Hydration

This is the place the magic happens. Using a hose with a great spray nozzle, start evenly saturating the cement blanket. Start from the pinnacle and work your way down on slopes to forestall water from pooling underneath the material. The purpose is a consistent, darkish gray shade throughout, indicating full saturation. Avoid the use of a high-pressure jet, as it can displace the cement particles. The cement blanket generally requires a unique quantity of water per rectangular meter; seek advice from the product guidelines. Proper hydration transforms the bendy cloth into a solid, monolithic erosion manage ditch liner material.

Post-Installation: Curing and Long-Term Performance

Your job is not pretty carried out after the water is applied. The curing technique is indispensable for electricity development.

Monitor the Initial Set

The cement blanket will firstly end up pliable after hydration. Do no longer disturb it at some stage in this phase. It will usually set to the contact inside a few hours. For culvert lining projects, make certain the shape stays out of carrier till the fabric has utterly cured to cope with hydraulic flow.

Ensure a Moist Cure

While the water resistant backing retains moisture, in warm or windy conditions, a mild misting of water after 12-24 hours can forestall plastic shrinkage cracking and promote a more advantageous cure. The cement blanket will acquire excessive early electricity rapidly, however full electricity develops over 28 days, like traditional concrete.

Final Inspection

Once cured, check out the floor for any free edges or unsecured areas. The end result have to be a hard, long lasting floor equipped to furnish long-term protection. As an erosion manipulate ditch liner material, it will now face up to wind and water, stabilizing slopes and channels effectively.

Conclusion: A Durable Future with Proper Installation

The cement blanket is greater than simply a product; it is a paradigm shift in how we follow concrete. By following these targeted steps for applicable placement and securing, you make certain that this modern cloth performs as supposed for years to come. From defending foundational slabs and developing impermeable culvert lining to deploying a exceptionally high quality erosion manage ditch liner material on difficult slopes, a right set up is the basis of success. Embrace this technology, grasp its application, and construct with self assurance and efficiency.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province