How HDPE Geomembrane Enhances Leakage Prevention in Landfill Sites

Landfills are essential for managing municipal and industrial waste, however they pose a most important environmental risk: leakage of leachate. Leachate—contaminated liquid shaped when rainwater mixes with decomposing waste—can seep into soil and groundwater, poisoning ecosystems and endangering public health. To mitigate this threat, engineers and waste administration experts be counted on a established barrier solution: HDPE Geomembrane. Unlike ordinary liners (e.g., clay or concrete), HDPE Geomembrane affords ultimate durability, flexibility, and leak resistance, making it the spine of current landfill leakage prevention systems. Below, we wreck down 4 key approaches HDPE Geomembrane safeguards landfills in opposition to leaks, from fabric science to real-world application.

1. HDPE Geomembrane’s Inherent Leak-Proof Material Properties

The first line of protection in opposition to landfill leakage lies in HDPE Geomembrane’s unique bodily and chemical characteristics. Unlike porous substances that enable liquid to seep thru over time, HDPE (High-Density Polyethylene) is engineered to create an impermeable barrier—even when uncovered to the most harsh landfill conditions.

1.1 Dense Molecular Structure Blocks Liquid Penetration

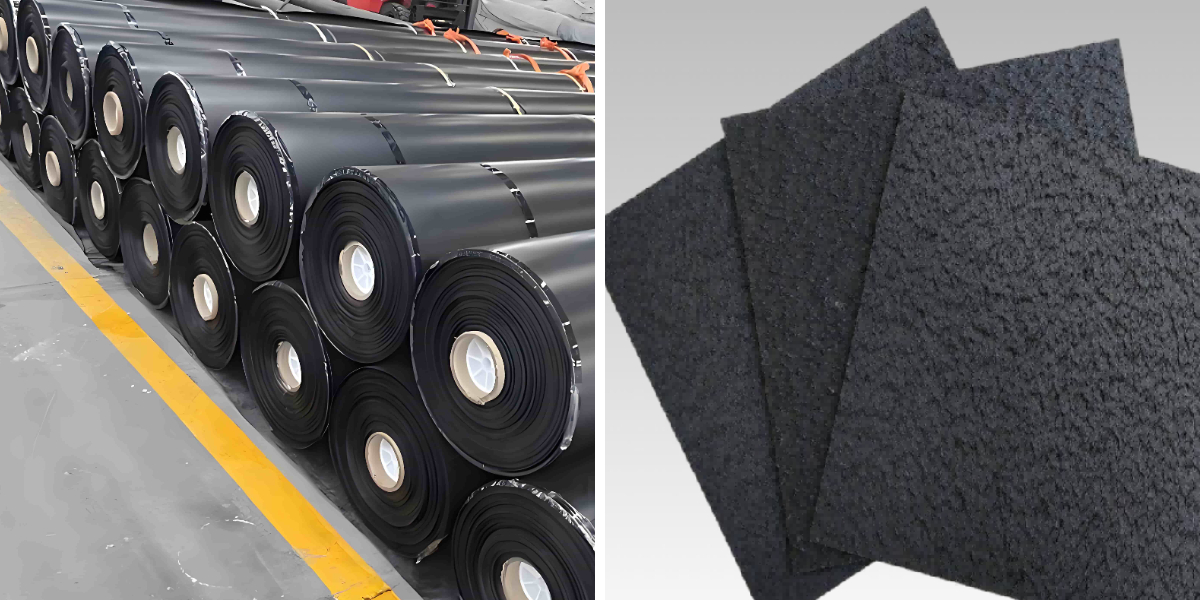

HDPE Geomembrane is made from high-density polyethylene pellets melted and extruded into thin, uniform sheets. Its molecular shape is tightly packed, with minimal gaps between polymer chains. This density ability water, leachate, and gases can't penetrate the cloth below everyday landfill pressure. Laboratory exams verify that top notch HDPE Geomembrane has a hydraulic conductivity of much less than 1 x 10⁻¹² cm/s—far under the threshold for “impermeable” set via environmental regulators. For landfills, this interprets to near-zero leachate migration via the geomembrane itself.

1.2 Chemical Resistance Against Aggressive Leachate

Landfill leachate is relatively corrosive. It includes natural acids, heavy metals (e.g., lead, mercury), and poisonous chemical substances that can damage down weaker liners like PVC or low-density polyethylene (LDPE). HDPE Geomembrane, however, resists degradation from these substances. Its inert nature prevents chemical reactions with leachate components, making sure the barrier remains intact for decades. For example, in industrial landfills dealing with hazardous waste, HDPE Geomembrane is the solely geomembrane kind licensed to stand up to long-term publicity to solvents and acidic compounds barring creating cracks or pores.

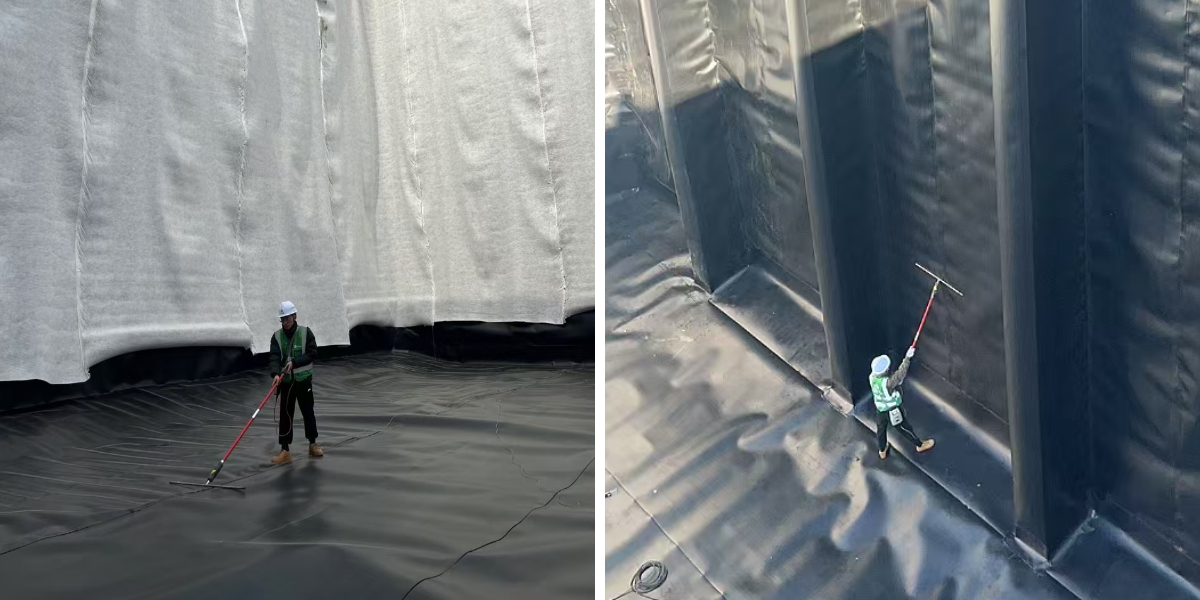

2. Seamless Installation: Eliminating Leakage Points with Precision Welding

Even the most impermeable geomembrane fails if its seams—where character rolls connect—are poorly sealed. Seams are the single largest vulnerability in any landfill liner system, however HDPE Geomembrane’s set up procedure is designed to do away with this hazard entirely.

2.1 Hot Air Welding: The Gold Standard for Seam Integrity

Professional installers use hot air welding (or extrusion welding for thicker sheets) to fuse HDPE Geomembrane rolls into a single, non-stop barrier. This technique heats the edges of two HDPE Geomembrane sheets to their melting factor (around 180–200°C) and presses them together, growing a bond superior than the geomembrane itself. Unlike adhesive-based seams (which degrade over time), welded HDPE seams withstand pulling, tearing, and leachate penetration.

2.2 Post-Welding Testing to Ensure Zero Gaps

No welding procedure is foolproof—so exceptional manipulate is critical. After putting in HDPE Geomembrane, groups behavior rigorous seam assessments to discover even microscopic gaps. The most frequent approach is vacuum field testing: a sealed container is positioned over the seam, and a vacuum is applied. If air (or smoke, in smoke tests) is drawn into the box, it shows a leak, which is straight away repaired. For giant landfills, electrical conductivity trying out is additionally used: electrodes are positioned on both facet of the seam, and a modern is applied. A drop in conductivity alerts a gap, permitting installers to restore it earlier than waste is deposited.

3. Synergy with Composite Liner Systems: HDPE Geomembrane as the Core

HDPE Geomembrane hardly ever works alone. It is section of a composite liner system—paired with geotextiles and drainage layers—that amplifies its leakage prevention power. This machine addresses a couple of dangers (e.g., punctures, hydraulic pressure) that a single geomembrane should no longer handle.

3.1 Geotextiles Protect HDPE Geomembrane from Punctures

Landfill waste carries sharp objects: damaged glass, steel scraps, and inflexible plastic. These can puncture a naked geomembrane, developing leaks. To stop this, a non-woven geotextile is positioned at once above or beneath the HDPE Geomembrane. The geotextile acts as a buffer, absorbing have an impact on and distributing stress evenly throughout the geomembrane surface. For example, in municipal strong waste (MSW) landfills, a 200-300 g/m² geotextile paired with 1.5 mm-thick HDPE Geomembrane reduces puncture hazard by using over 90%.

3.2 Drainage Layers Reduce Hydraulic Pressure on the Geomembrane

Leachate buildup creates hydraulic stress on the geomembrane. If strain turns into too high, it can pressure liquid thru tiny seams or defects. Composite structures encompass a drainage layer (e.g., gravel or geonet) above the HDPE Geomembrane to gather and channel leachate to pumps. By eliminating extra leachate, the drainage layer continues strain low—ensuring the geomembrane stays flat and leak-free. In giant landfills, this layer can divert heaps of gallons of leachate daily, defending the HDPE Geomembrane from stress.

4. Long-Term Durability and Maintenance: Sustaining Leak Protection for Decades

Landfills function for 20–30 years (or longer for closed web sites below post-closure care). For a liner to be effective, it ought to preserve its integrity over this whole lifespan. HDPE Geomembrane excels here, thanks to its resistance to getting older and ease of maintenance.

4.1 UV and Weather Resistance

Exposed HDPE Geomembrane (e.g., on landfill caps) faces harsh sunlight, temperature fluctuations, and rain. Unlike LDPE, HDPE is stabilized with UV inhibitors that forestall degradation from photo voltaic radiation. It additionally stays bendy in bloodless temperatures (down to -40°C) and does no longer crack in heat, making sure the barrier stays intact thru seasonal changes. Studies exhibit that top established HDPE Geomembrane retains over 80% of its power after 25 years of outside exposure.

4.2 Simple Inspection and Repair Protocols

Even with sturdy design, ordinary renovation is key to stopping leaks. HDPE Geomembrane’s easy floor makes visible inspections easy—teams can spot tears, punctures, or seam injury quickly. Repairs are equally straightforward: small holes are patched with HDPE tape (welded in place), whilst large defects are constant by using reducing out the broken area and welding a new HDPE Geomembrane patch. This low-cost, quick renovation ensures the liner stays leak-proof barring disrupting landfill operations.

Why HDPE Geomembrane Is Non-Negotiable for Landfill Leakage Prevention

Landfill leakage is now not simply an environmental issue—it is a criminal and monetary one. Fines for groundwater infection can attain hundreds of thousands of dollars, and cleanup efforts take years. HDPE Geomembrane eliminates these dangers through combining impermeability, durability, and ease of installation. It is the solely geomembrane kind that meets international requirements (e.g., ASTM D751, ISO 14663) for landfill liners, making it the default preference for engineers, waste managers, and regulators worldwide.

For any landfill project—whether municipal, industrial, or hazardous waste—investing in gorgeous HDPE Geomembrane and expert set up is the most fine way to defend soil, groundwater, and public health.

Contact Us

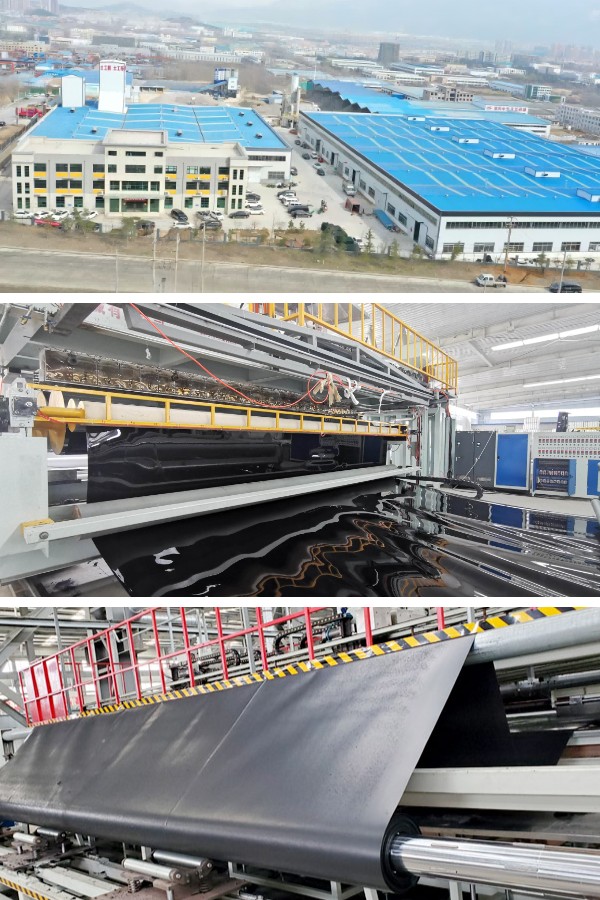

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province