How Geomembranes Help Meet EPA & Environmental Regulations

The United States Environmental Protection Agency (EPA) performs a essential function in safeguarding the surroundings and public health. Since its institution in 1970, the EPA has been tasked with developing and imposing a huge vary of environmental regulations. These rules cowl numerous elements such as air quality, water quality, waste management, and soil contamination. For instance, the Clean Air Act, enforced via the EPA, units strict requirements for air pollution to minimize smog, acid rain, and different hazardous consequences on the atmosphere. The Clean Water Act targets to defend and fix the nation's water our bodies by using regulating the discharge of pollution into water sources.

Compliance with these rules is now not solely a criminal duty for industries however additionally critical for the lengthy - time period properly - being of the planet. Non - compliance can lead to vast fines, felony actions, and injury to a company's reputation. For example, a manufacturing plant that illegally discharges untreated wastewater into a close by river may also face giant monetary penalties and terrible public perception.

The Role of Geomembranes in Environmental Protection

Geomembranes are artificial membranes made from polymers like excessive - density polyethylene (HDPE). They have emerge as necessary in a variety of environmental safety applications. These thin, impermeable sheets act as a barrier to forestall the migration of drinks and gases, defending the surroundings from contamination.

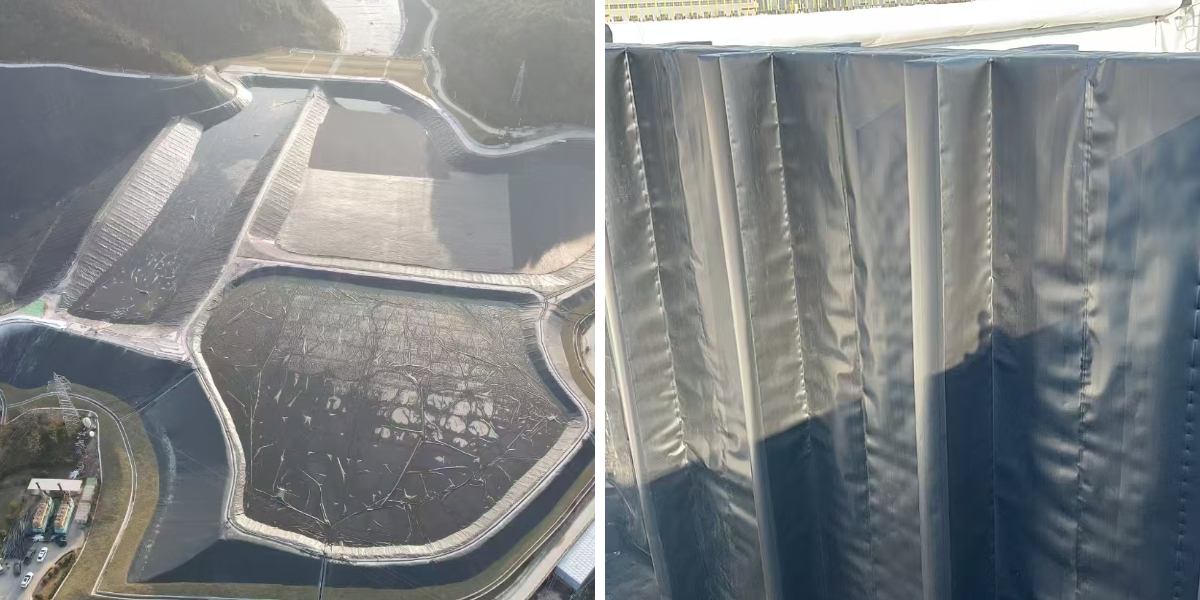

HDPE geomembranes, in particular, are relatively resistant to chemicals, UV radiation, and organic degradation. Their sturdiness and flexibility make them appropriate for a large vary of projects. For example, in landfill sites, HDPE geomembranes are used to line the backside and aspects of the landfill. This prevents leachate, a extraordinarily polluted liquid generated from the decomposition of waste, from seeping into the surrounding soil and groundwater. A easy geomembrane, such as HDPE liner, presents an high-quality seal, decreasing the danger of environmental contamination. In the building of reservoirs and canals, geomembranes are used to forestall water seepage, conserving water sources and defending the underlying soil from water - brought on erosion. Their position in environmental safety is fundamental, and they serve as a key device in supporting industries meet the stringent necessities set via the EPA and different environmental regulations.

Types of Geomembranes and Their Features

HDPE Liner: High - Density Polyethylene Liner

HDPE liners are a kind of geomembrane made from excessive - density polyethylene. One of their most distinguished facets is their magnificent chemical resistance. They can face up to publicity to a large vary of chemicals, which includes acids, alkalis, and industrial waste. This chemical resistance is fundamental in functions such as chemical waste storage facilities. For example, in a chemical plant the place a variety of hazardous chemical compounds are stored, an HDPE liner is used to line the storage tanks and containment areas. The liner prevents the chemical substances from seeping into the soil and groundwater, for that reason assembly the EPA's strict rules on the containment of hazardous substances.

HDPE liners additionally possess excessive tensile strength. This energy approves them to suffer considerable stress and pressure besides tearing or puncturing. In landfill applications, the liner has to stand up to the weight of the waste being deposited on it over time, as properly as the motion and agreement of the waste. The excessive tensile electricity of the HDPE liner ensures its integrity is maintained, efficiently stopping leachate leakage and defending the surrounding surroundings from contamination.

HDPE Geomembrane: The Workhorse of Geomembranes

HDPE geomembranes are extensively used in a plethora of environmental projects, making them the workhorse of geomembranes. In the building of landfills, HDPE geomembranes are used as the essential barrier to stop leachate from contaminating the soil and groundwater. Their resistance to organic degradation is a key benefit in this application. Since landfills are stuffed with decomposing natural be counted and microorganisms, the HDPE geomembrane's potential to face up to organic assault ensures its lengthy - time period effectiveness.

In pond and reservoir lining projects, HDPE geomembranes play a integral function in water conservation. They forestall water seepage, which is no longer solely necessary for retaining the water degree in the pond or reservoir but additionally for defending the underlying soil from water - prompted erosion. In accordance with environmental regulations, these initiatives want to make sure that water sources are conserved and that there is no terrible affect on the surrounding environment. The use of HDPE geomembranes helps meet these necessities with the aid of imparting an advantageous water resistant barrier.

Smooth Geomembrane: Special Advantages

Smooth geomembranes, such as easy HDPE geomembranes, have a number of different advantages. One of the important blessings is their low coefficient of friction. This attribute makes them simpler to install, specifically in massive - scale projects. For example, in the lining of a massive - scale canal, the clean floor of the geomembrane lets in it to be unrolled and laid greater rapidly in contrast to a textured geomembrane. This now not solely reduces the set up time however additionally minimizes the workable for harm throughout installation.

The easy floor additionally contributes to higher waft characteristics. In functions the place beverages want to float over the geomembrane, such as in some industrial wastewater therapy systems, the easy floor reduces drift resistance. This ensures that the wastewater can be efficaciously dealt with and disposed of in compliance with environmental regulations. Additionally, the clean floor is much less probably to accumulate particles or sediment, which helps keep the overall performance of the geomembrane over time.

How Geomembranes Meet EPA and Environmental Regulations

Containment and Leak Prevention

In landfills, HDPE geomembranes are established as liners at the backside and aspects of the landfill pits. These liners act as a most important barrier in opposition to leachate. Leachate is a fairly contaminated liquid that is generated as waste decomposes in the landfill. It carries a number pollution such as heavy metals (like lead, mercury, and cadmium), natural compounds, and pathogens. Without an positive containment machine like HDPE liners, this leachate can seep into the underlying soil. Once in the soil, it can contaminate the groundwater, which is a foremost supply of consuming water for many communities. The EPA has strict policies concerning the containment of landfill leachate to guard groundwater quality. HDPE geomembranes, with their low permeability, efficaciously stop leachate from migrating into the soil and groundwater, making sure compliance with these regulations.

Similarly, in wastewater remedy plants, easy geomembranes are used to line therapy ponds and storage tanks. Wastewater regularly includes excessive ranges of chemical pollutants, along with nitrates, phosphates, and industrial chemicals. If this wastewater have been to leak from the remedy facilities, it ought to contaminate close by floor water our bodies such as rivers and lakes. Smooth geomembranes, like easy HDPE geomembranes, supply a seamless and impermeable barrier. Their easy floor additionally reduces the possibilities of small cracks or imperfections that should doubtlessly lead to leakage, accordingly assisting wastewater remedy flora meet EPA's water air pollution manage regulations.

Chemical Resistance and Durability

HDPE geomembranes are relatively resistant to a vast vary of chemicals. In industrial settings, the place chemical waste storage is a frequent requirement, this chemical resistance is of utmost importance. For example, in a manufacturing plant that produces or makes use of chemical compounds such as acids (sulfuric acid, hydrochloric acid) and alkalis (sodium hydroxide, potassium hydroxide), the storage tanks and containment areas are lined with HDPE liners. These liners can stand up to the corrosive consequences of these chemical compounds over lengthy periods.

The sturdiness of geomembranes ensures that they hold their integrity and overall performance over time. Environmental policies regularly require that waste administration and containment amenities have a lengthy - time period lifespan to decrease the hazard of contamination. HDPE geomembranes can closing for decades, even when uncovered to harsh environmental stipulations such as UV radiation, temperature fluctuations, and mechanical stress. In landfill applications, the HDPE geomembrane liner has to suffer the weight of the waste, the motion of the waste as it decomposes, and the workable for puncture from sharp objects in the waste. Its excessive tensile energy and resistance to degradation make certain that it can function its characteristic of stopping leachate leakage at some point of the lifespan of the landfill, which can be 30 years or greater in some cases. This lengthy - time period sturdiness helps landfill operators meet the EPA's necessities for the suited administration and containment of waste over prolonged periods.

Ease of Installation and Maintenance in Compliance

Geomembranes, specially HDPE geomembranes, are exceedingly effortless to install. In giant - scale environmental tasks such as landfill building or the lining of massive reservoirs, the ease of set up is a great advantage. The set up technique of HDPE geomembranes entails unrolling the sheets and then welding them together. The welding methods used, such as extrusion welding or warm - wedge welding, are nicely - mounted and can be carried out correctly via skilled professionals. This ease of set up helps building initiatives meet regulatory closing dates for completion. For example, in a landfill enlargement project, a speedy and appropriate set up of the HDPE geomembrane liner ensures that the new landfill location can be put into use in a well timed manner, whilst additionally assembly the EPA's necessities for applicable containment all through the building phase.

Maintenance of geomembranes is additionally straightforward, which is vital for lengthy - time period compliance. Regular inspections can be carried out to test for any signs and symptoms of damage, such as punctures or tears. In case of minor damage, repairs can be without difficulty made with the aid of patching the affected area. For example, if a small puncture is detected in a clean geomembrane used in a pond lining, a patch of the identical fabric can be welded over the puncture site. This easy upkeep method helps to make sure that the geomembrane continues to characteristic efficaciously in stopping seepage or leakage, for that reason preserving the facility in compliance with environmental regulations. In contrast, greater complicated or much less long lasting containment structures may additionally require normal and pricey maintenance, growing the chance of non - compliance due to device disasters all through preservation periods.

Case Studies

Landfill Projects

In a landfill challenge in a mid - sized city, strict compliance with EPA rules was a pinnacle priority. The landfill was once in an vicinity with a high water table, making the prevention of leachate leakage into the groundwater crucial. HDPE geomembranes had been chosen as the essential lining material.

During the set up process, the HDPE geomembrane used to be cautiously unrolled and laid over the organized sub - grade of the landfill pit. The seams have been welded collectively the use of warm - wedge welding techniques. Rigorous exceptional manage measures had been implemented, inclusive of non - unfavorable trying out of the welds the usage of strategies like vacuum container trying out and ultrasonic testing. This ensured that the liner had no gaps or holes that should doubtlessly permit leachate to escape.

As a result, over the years of operation, the landfill has efficaciously contained the leachate. Regular monitoring of the groundwater high-quality in the surrounding region has proven that the degrees of pollution such as heavy metals and natural compounds continue to be properly inside the EPA - mandated limits. The use of the HDPE geomembrane has efficaciously avoided soil and groundwater pollution, demonstrating how geomembranes can meet and exceed EPA's landfill - associated regulations.

Wastewater Treatment Plants

A giant - scale wastewater cure plant in an industrial location serves more than one factories and a good sized element of the nearby community. The plant wished to meet strict environmental rules related to the remedy and disposal of wastewater.

Smooth HDPE geomembranes have been used to line the remedy ponds and storage tanks inside the plant. The clean floor of the geomembrane facilitated the environment friendly waft of wastewater at some stage in the therapy process. It additionally decreased the adhesion of sludge and different contaminants, making the renovation of the remedy amenities easier.

In addition to lining, the geomembranes additionally furnished a dependable barrier to stop any leakage of partly dealt with or untreated wastewater. This used to be integral as the wastewater contained excessive stages of chemical pollution from industrial processes, as properly as organic contaminants from home sewage. By the usage of clean HDPE geomembranes, the plant was once in a position to make certain that there was once no illness of the close by floor water bodies, such as a river that flowed thru the area. Regular water first-rate trying out of the river, as required with the aid of environmental regulations, has proven that the water stays protected and appropriate for its unique uses, such as leisure things to do and as a supply of water for sure industrial techniques downstream. This case learn about highlights how geomembranes play a crucial function in assisting wastewater therapy vegetation meet environmental rules and protect water resources.

Conclusion

Summarize the Significance

Geomembranes, specifically HDPE liners, HDPE geomembranes, and easy geomembranes, play a pivotal position in assembly EPA and environmental regulations. Their potential to forestall leakage, face up to chemicals, and provide lengthy - time period sturdiness makes them critical in waste management, water treatment, and different environmentally touchy projects. By presenting an positive barrier, they protect soil, water, and air quality, defending ecosystems and public health.

Looking Ahead

As environmental rules proceed to evolve and come to be greater stringent, the function of geomembranes will solely end up greater important. Future lookup and improvement may additionally lead to even extra superior geomembrane substances with improved properties, such as higher chemical resistance, multiplied UV stability, and higher flexibility. More industries and tasks are stimulated to undertake geomembranes in their building and waste administration practices. By doing so, they can make certain compliance with regulations, defend the environment, and make contributions to a greater sustainable future.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province