HDPE Geomembranes for Landfills: Design, Specification, and Compliance

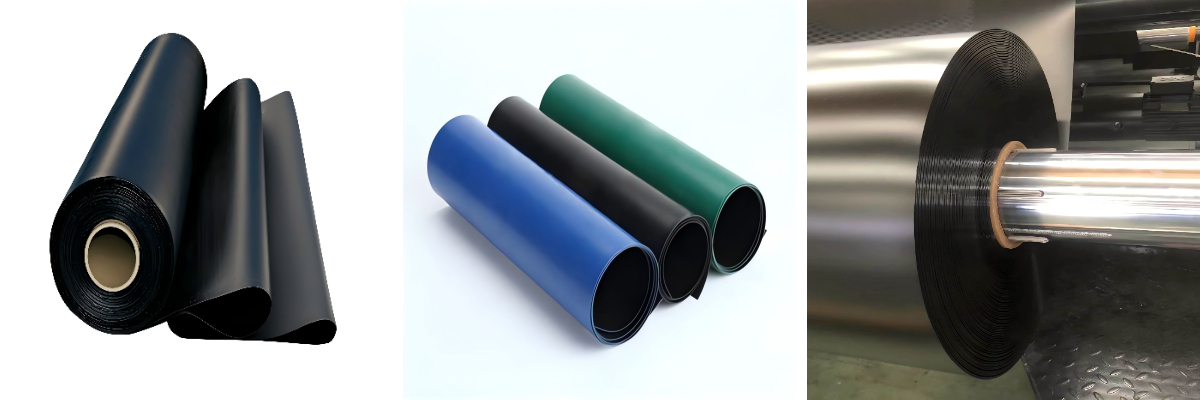

Landfills are necessary factors of waste administration systems, however they pose substantial environmental dangers if now not suitable contained. Leachate—toxic liquid generated through decomposing waste—and methane gasoline can seep into groundwater, soil, and the atmosphere, inflicting illness and local weather impacts. This is the place hdpe geomembrane emerges as a cornerstone solution. As the gold popular impermeable geomembrane liner for landfills, HDPE (high-density polyethylene) presents a sturdy barrier that prevents leakage and ensures long-term environmental protection. However, success relies upon on three key pillars: considerate design, particular specification, and strict regulatory compliance. This information breaks down every pillar, exploring how to optimize geomembrane liner landfill systems the use of HDPE to meet safety, durability, and felony requirements.

The Critical Role of HDPE Geomembrane in Landfill Design

A landfill’s containment gadget is solely as robust as its liner, and hdpe geomembrane is uniquely suitable for this worrying application. Unlike different liner materials, HDPE combines extremely good impermeability with chemical resistance, flexibility, and durability—addressing the special challenges of landfill environments.

The foremost characteristic of an impermeable geomembrane liner in landfills is to create a barrier between the waste and the surrounding environment. HDPE’s dense molecular shape minimizes leachate and fuel migration, whilst its flexibility permits it to conform to uneven landfill terrain besides cracking. In contemporary landfill designs, HDPE liners are normally used as phase of a composite system: a fundamental liner without delay below the waste, a secondary liner (often some other HDPE layer) as a backup, and a leachate series machine between them to seize any seepage. This redundant sketch ensures failsafe protection, even if one layer is compromised.

Design concerns for HDPE geomembranes additionally encompass slope balance and anchoring. Landfill slopes require liners that can face up to sliding, so HDPE is regularly textured on one aspect to enhance friction with the underlying soil or geotextile. Anchoring systems—such as trench anchors alongside the landfill perimeter—secure the liner to stop shifting, making sure the geomembrane liner landfill stays intact at some stage in waste placement and settlement.

Key Specifications for Landfill-Grade HDPE Geomembranes

Not all HDPE geomembranes are created equal. Landfill purposes demand specialised specs to face up to harsh conditions, which includes chemical exposure, UV radiation, and mechanical stress. Here are the necessary parameters to outline when choosing an impermeable geomembrane liner:

1. Thickness

Landfill-grade hdpe geomembrane usually stages in thickness from a minimal of 1.5mm to 3mm or more. Thicker liners provide larger puncture resistance and durability, making them best for landfills with sharp waste or heavy gear traffic. Thinner liners may additionally be used for secondary backup layers, however predominant liners ought to prioritize thickness to deal with direct contact with waste.

2. Material Properties

Critical cloth homes consist of tensile strength, elongation at break, and chemical resistance. HDPE liners for landfills must have excessive tensile electricity to face up to stretching for the duration of landfill settlement, and adequate elongation to accommodate minor floor shifts. Chemical resistance is non-negotiable—HDPE ought to stand up to leachate’s acidic or alkaline nature except degrading. Look for liners made from virgin HDPE resin, as recycled content material can also introduce impurities that compromise performance.

3. Seam Quality

Seams are the most inclined factors in any geomembrane liner landfill system. Landfill HDPE liners require warmth fusion seams (either warm wedge or extrusion welding) that create a molecular bond between sheets. Specifications must mandate seam energy testing—such as peel and shear tests—to make certain seams are as robust as the liner itself. Extrusion welding is frequently favored for necessary areas, as it provides a bead of molten HDPE to toughen the seam.

4. UV Stabilization

While HDPE liners are specially buried under waste, uncovered sections (e.g., in the course of set up or landfill capping) want UV protection. Specifications need to require UV stabilizers to stop photo-oxidation, which can make the liner brittle and inclined to cracking. This is mainly necessary for landfill caps, the place the liner may also be uncovered to daylight for prolonged periods.

Regulatory Compliance: Meeting Landfill Liner Standards

Landfill containment structures are closely regulated to defend public fitness and the environment. Compliance with local, national, and global requirements is non-negotiable when putting in an hdpe geomembrane liner. Here’s what you want to know:

1. Global and Regional Standards

Major requirements governing geomembrane liner landfill structures consist of ASTM International requirements (e.g., ASTM D4716 for HDPE geomembranes) and ISO requirements (e.g., ISO 14663 for geomembrane testing). These requirements outline fabric requirements, checking out methods, and set up practices. Regional guidelines may additionally add unique requirements—for example, the U.S. EPA’s Subtitle D requirements for municipal strong waste landfills mandate minimal liner thickness, leachate series systems, and monitoring protocols.

2. Leachate and Gas Monitoring

Compliance isn’t simply about liner installation—it additionally requires ongoing monitoring. Landfills should put into effect leachate monitoring structures (e.g., groundwater wells round the site) to discover any seepage. Methane gasoline monitoring is additionally mandatory, as HDPE liners play a position in fuel containment for strength restoration or flaring. Regular trying out ensures the impermeable geomembrane liner is functioning as meant and permits for rapid motion if problems arise.

3. Documentation and Quality Control

Regulators require complete documentation during the liner lifecycle. This consists of cloth take a look at reviews (proving HDPE meets specifications), set up logs (detailing seam checking out and anchor placement), and monitoring records. Quality manipulate at some stage in set up is critical—third-party inspectors frequently affirm seam strength, liner thickness, and applicable anchoring to make certain compliance earlier than waste placement begins.

Installation Best Practices for Landfill HDPE Geomembranes

Even the best-specified hdpe geomembrane will fail except suitable installation. Follow these fine practices to make certain a dependable geomembrane liner landfill system:

Site Preparation: Clear the landfill base of rocks, debris, and sharp objects that ought to puncture the liner. Use a non-woven geotextile underlay to add an more layer of protection.

Weather Considerations: Avoid putting in liners in severe temperatures (too warm or too cold) or moist conditions, as this can compromise seam quality. Windy prerequisites must additionally be avoided, as they can motive liner sheets to shift all through placement.

Seam Testing: Test each and every seam the use of vacuum trying out (for warm wedge seams) or spark trying out (for extrusion seams) to become aware of leaks. Repair any misguided seams at once and retest.

Waste Placement: Start waste placement gently to keep away from adverse the liner. Use light-weight tools for preliminary compaction, and keep away from dragging sharp waste throughout the liner surface.

Conclusion: HDPE Geomembranes—The Foundation of Safe Landfills

Hdpe geomembrane is the spine of current landfill containment systems, providing the impermeability, durability, and chemical resistance wished to shield the environment. By focusing on considerate layout (including composite liner systems and slope stability), unique specs (thickness, fabric properties, seam quality), and strict regulatory compliance, landfill operators can make sure their geomembrane liner landfill device performs reliably for decades.

Investing in magnificent HDPE and following quality practices isn’t simply a prison requirement—it’s a dedication to environmental stewardship. A well-designed and mounted impermeable geomembrane liner prevents contamination, reduces greenhouse fuel emissions, and ensures landfills function safely for communities and ecosystems alike. For landfills, HDPE geomembranes aren’t simply a cloth choice—they’re a quintessential thing of accountable waste management.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province