Geotextile Cloth Maintenance: Inspection, Repair & Longevity Tips

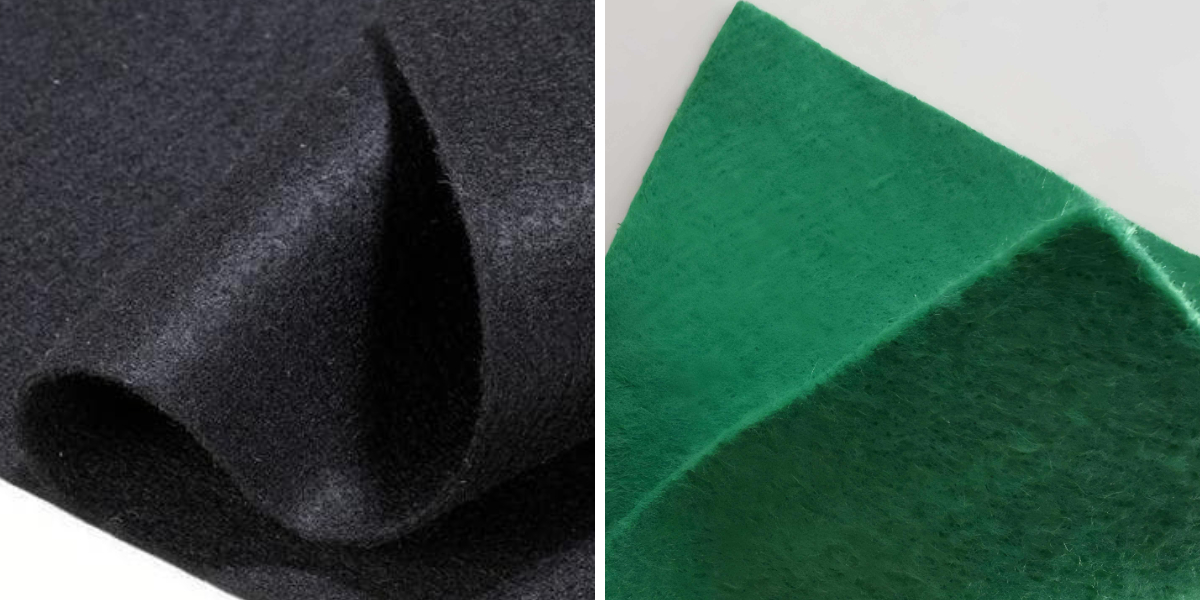

Geotextile Cloth is a versatile and imperative cloth in civil engineering, construction, agriculture, and environmental safety projects. Whether you use woven or non woven geotextile, acceptable protection is necessary to retaining its structural integrity, practical performance, and extending its carrier life. Neglecting Geotextile upkeep can lead to untimely degradation, compromised undertaking safety, and useless substitute costs. In this guide, we’ll discover 4 key factors of Geotextile Cloth maintenance—regular inspection, centered repair, longevity-boosting strategies, and each day care habits—providing actionable guidelines to preserve your geotextile substances in top-quality condition.

1. Regular Inspection: The Foundation of Geotextile Cloth Maintenance

Routine inspection is the first line of protection towards Geotextile degradation. It lets in you to become aware of minor troubles earlier than they amplify into most important damages, ensuring the fabric continues to operate its meant features (e.g., filtration, separation, reinforcement, or erosion control). The frequency and center of attention of inspections differ primarily based on the application, environmental conditions, and the kind of Geotextile (woven or non woven geotextile), however a structured inspection design is non-negotiable.

1.1 Inspection Frequency Guidelines

For most functions (e.g., street construction, panorama erosion control), habits a visible inspection month-to-month for the first six months after installation—this is when Geotextile Cloth is most inclined to preliminary put on and tear. After the preliminary period, swap to quarterly inspections for the first year, then semi-annual inspections thereafter. In high-stress environments (e.g., areas with heavy rainfall, robust winds, customary foot traffic, or industrial runoff), make bigger inspections to bi-weekly initially, then month-to-month indefinitely. Following intense climate activities (hurricanes, floods, or extreme storms), constantly operate an instantaneous post-event inspection to examine harm from particles impact, water pressure, or soil displacement.

1.2 Key Inspection Focus Areas for Woven & Non Woven Geotextile

When inspecting Geotextile Cloth, pay shut interest to the following necessary areas, adjusting your focal point primarily based on whether or not you’re working with woven or non woven geotextile:

Surface Damage: Look for tears, punctures, fraying, or abrasions. Woven geotextile is commonly greater resistant to abrasion however can tear alongside weft/warp traces if subjected to sharp impacts, whilst non woven geotextile is susceptible to fiber breakdown and floor abrasion from regular friction.

Edge Integrity: Check the edges of the Geotextile Cloth for unraveling or separation from anchors (e.g., stakes, trenches, or adhesive bonds). Edges are frequent failure points, as they undergo the brunt of environmental stress and mechanical tension.

Moisture & Contamination: Inspect for standing water, mould growth, or chemical illness (e.g., oil, fertilizer, or industrial chemicals). Excess moisture can weaken non woven geotextile fibers over time, whilst chemical compounds can degrade each woven and non woven geotextile materials.

Installation Alignment: Ensure the Geotextile Cloth stays true tensioned and aligned. Sagging or transferring can create pockets for water accumulation, main to erosion underneath the cloth and untimely failure.

UV Degradation: Look for signs and symptoms of discoloration (fading to yellow or brown), brittleness, or powdery residue—these are symptoms of UV damage. Non woven geotextile is regularly greater inclined to UV degradation than woven varieties, in particular if no longer dealt with with UV stabilizers.

2. Targeted Repair: Addressing Geotextile Cloth Damages Promptly

Even with normal inspections, Geotextile Cloth might also maintain harm over time. Prompt and suited restore is crucial to forestall the injury from spreading and compromising the material’s performance. The restore approach relies upon on the type of damage, the Geotextile cloth (woven or non woven geotextile), and the application. Below are the most frequent damages and their corresponding restore techniques.

2.1 Repairing Tears & Punctures

Tears and punctures are the most usual damages to Geotextile Cloth, regularly induced by means of sharp objects (rocks, tools, or debris) or immoderate tension. For small tears (less than 6 inches) or punctures:

Non Woven Geotextile: Use a patch of the equal or well suited non woven geotextile material. Cut the patch to be at least three inches large than the broken region on all sides. Clean the broken vicinity entirely to do away with dirt, moisture, and unfastened fibers. Apply a geotextile-compatible adhesive to the patch and press it firmly onto the broken area, making sure full contact. Allow the adhesive to therapy in accordance to the manufacturer’s directions (typically 24–48 hours) earlier than exposing the location to stress or moisture.

Woven Geotextile: For small tears, use a woven geotextile patch and both adhesive or stitching. Stitching is favored for high-tension applications, as it presents a greater bond. Use a heavy-duty thread (e.g., polyester or nylon) and a zigzag sew round the perimeter of the patch, making sure the sew penetrates each the patch and the authentic Geotextile Cloth. For large tears (over 6 inches), overlap two portions of Geotextile Cloth with the aid of at least 12 inches and sew or adhere the overlap to create a robust seam.

2.2 Fixing Edge Unraveling & Separation

Edge unraveling is frequent in each woven and non woven geotextile, specifically if the edges have been no longer appropriate sealed or anchored at some point of installation. To restore unraveling edges:

Trim the frayed edges with sharp scissors to create a clean, straight edge.

Fold the facet again on itself by using 2–3 inches and invulnerable it with stitches (for woven geotextile) or adhesive (for non woven geotextile).

Re-anchor the repaired facet the usage of stakes, trenches, or geotextile anchors. Ensure the anchor is invulnerable and distributes anxiety evenly throughout the aspect to forestall future unraveling.

2.3 Mitigating UV Damage

If Geotextile Cloth indicates symptoms of moderate UV harm (e.g., moderate discoloration), you can lengthen its lifestyles via making use of a UV-protective coating mainly formulated for geotextile materials. For extreme UV harm (brittleness, giant areas of degradation), alternative is necessary, as the material’s structural integrity is compromised. To stop future UV damage, select Geotextile Cloth with UV stabilizers in the course of installation, in particular for out of doors applications.

3. Longevity-Boosting Strategies: Protecting Geotextile Cloth from Environmental Stress

Proactive safety towards environmental stressors is key to extending the carrier lifestyles of Geotextile Cloth. Whether you use woven or non woven geotextile, the following techniques will assist reduce degradation and maximize performance.

3.1 UV Protection

UV radiation is one of the essential motives of Geotextile degradation. To defend in opposition to UV damage:

Choose Geotextile Cloth with built-in UV stabilizers. Most producers provide UV-stabilized varieties, which are fundamental for out of doors purposes uncovered to direct sunlight.

Cover uncovered Geotextile Cloth with a layer of soil, mulch, or different protecting material. This bodily barrier blocks UV rays and reduces direct exposure. For example, in erosion manipulate projects, cowl the Geotextile with 2–3 inches of topsoil after installation.

Apply UV-protective sprays or coatings annually, mainly for Geotextile Cloth used in high-sunlight areas (e.g., wasteland areas or open landscapes).

3.2 Soil & Water Erosion Control

Soil erosion and water strain can reason untimely put on on Geotextile Cloth. To mitigate these risks:

Ensure acceptable drainage round the Geotextile installation. Install French drains, perforated pipes, or different drainage structures to stop water accumulation, which can exert immoderate strain on the Geotextile Cloth and purpose stretching or tearing.

Use gorgeous Geotextile kind for the soil condition. For cohesive soils (e.g., clay), non woven geotextile is perfect for filtration, whilst woven geotextile presents higher reinforcement for granular soils (e.g., sand or gravel).

Avoid putting heavy gear or immoderate masses without delay on the Geotextile Cloth, as this can compact the soil beneath and reason the fabric to stretch or tear. Use plywood or different brief covers when working close to the Geotextile.

3.3 Chemical & Biological Protection

Chemical illness (e.g., oil, pesticides, or industrial waste) and organic boom (e.g., mold, mildew, or plant roots) can degrade Geotextile Cloth. To guard towards these threats:

Avoid putting in Geotextile Cloth in areas with excessive chemical publicity until the usage of a chemical-resistant range (e.g., polyester geotextile, which is greater resistant to chemical substances than polypropylene).

Regularly easy the Geotextile floor to do away with debris, natural matter, and chemical spills. Use moderate cleaning soap and water for cleaning—avoid harsh chemical substances that can injury the material.

Prevent plant roots from penetrating the Geotextile Cloth via putting in a root barrier layer below or the use of a Geotextile material designed to withstand root intrusion (common in panorama and agricultural applications).

4. Daily Care Habits: Sustaining Geotextile Cloth Performance Long-Term

In addition to ordinary inspections and proactive protection, adopting day by day care habits can considerably lengthen the lifestyles of Geotextile Cloth. These habits are simple, cost-effective, and effortless to combine into events undertaking maintenance.

4.1 Proper Handling During Maintenance Activities

When performing upkeep close to Geotextile Cloth, keep away from moves that can purpose damage:

Use sharp equipment (e.g., shovels, scissors) cautiously to keep away from puncturing or tearing the Geotextile. Wrap device blades with tape if working in shut proximity to the material.

Do no longer drag heavy equipment, rocks, or particles throughout the Geotextile Cloth. Lift and raise these objects instead, or use a transient shielding cover.

Avoid over-tensioning the Geotextile for the duration of repairs or adjustments. Follow the manufacturer’s suggestions for anxiety ranges to forestall stretching and weakening of the material.

4.2 Regular Cleaning & Debris Removal

Debris (e.g., leaves, branches, dirt) can accumulate on Geotextile Cloth, trapping moisture and advertising mould boom or UV damage. Schedule month-to-month particles elimination the usage of a soft-bristled broom, leaf blower, or mild water spray. For cussed debris, use a moderate detergent and a gentle brush—avoid high-pressure water jets, which can harm non woven geotextile fibers.

4.3 Documentation & Scheduled Maintenance

Maintain a particular renovation log for your Geotextile Cloth installation. Record inspection dates, findings, restore activities, and any environmental activities (e.g., storms, chemical spills) that can also have an effect on the material. This log helps you song the Geotextile’s situation over time, become aware of patterns of damage, and agenda proactive renovation (e.g., UV coating applications, re-anchoring) earlier than troubles arise. Additionally, evaluation the manufacturer’s assurance and upkeep suggestions in many instances to make sure compliance and maximize the material’s lifespan.

Conclusion: Invest in Maintenance for Long-Lasting Geotextile Performance

Proper renovation of Geotextile Cloth—including ordinary inspection, centered repair, proactive environmental protection, and day by day care—is indispensable to maintaining its structural integrity, purposeful performance, and carrier life. Whether you use woven or non woven geotextile, these practices limit alternative costs, make certain assignment safety, and maximize the return on your Geotextile investment. By following the recommendations outlined in this guide, you can preserve your Geotextile Cloth in most excellent circumstance for years to come, making sure it continues to meet the needs of your application.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province