Eco-Friendly Aspects of Concrete Impregnated Fabric in Construction

Introduction: A Sustainable Shift in Building Materials

In an generation the place building sustainability is no longer an alternative however a necessity, concrete impregnated cloth has emerged as a game-changer. This modern cloth combines the power of concrete with the flexibility of fabric, imparting a eco-conscious choice to regular constructing materials. From 8mm Concrete Cloth to versatile Cement Blanket , these merchandise are redefining how we method construction, decreasing environmental affect besides compromising on performance. This article explores the eco-friendly advantages of concrete cloth constructing and why it’s turning into a pinnacle preference for inexperienced development projects.

Reduced Material Waste: Efficiency in Production and Use

Minimal Raw Material Consumption

Concrete impregnated material is engineered to be especially material-efficient. Unlike standard concrete, which frequently requires extra combinations to account for pouring and curing losses, 8mm Concrete Cloth is pre-measured and pre-impregnated with a particular quantity of dry concrete. This focused method reduces the want for surplus materials, slicing down on uncooked cloth extraction and waste. For example, a single roll of Cement Blanket can cowl a unique vicinity with minimal trimming, making sure nearly no leftover cloth on-site.

Lower Transportation Emissions

The light-weight nature of concrete material constructing substances is a key eco-friendly advantage. Compared to heavy precast concrete panels or moist concrete mixes, 8mm Concrete Cloth is simpler to transport, requiring fewer journeys and much less fuel. This discount in transportation needs immediately lowers carbon emissions, making it a greener desire for tasks in far off or hard-to-reach areas the place logistics can extensively have an impact on a project’s carbon footprint.

Energy Efficiency: From Manufacturing to Installation

Reduced Production Energy

Manufacturing usual concrete is energy-intensive, involving high-temperature kilns for cement production. Concrete impregnated fabric, however, streamlines this process. The dry concrete used in 8mm Concrete Cloth is cured with water on-site alternatively than in energy-consuming factories, reducing down on industrial power use. Additionally, the cloth base—often made from recycled polyester—requires much less electricity to produce than the metal reinforcements used in traditional concrete, in addition reducing the material’s embodied energy.

Faster, Low-Energy Installation

Concrete material constructing simplifies on-site work, lowering electricity needs in the course of installation. Unlike usual concrete, which requires heavy equipment for mixing, pouring, and finishing, Cement Blanket can be unrolled, reduce to size, and activated with water the usage of simple tools. This eliminates the want for fuel-powered tools like mixers or pumps, reducing on-site electricity consumption. Projects the usage of 8mm Concrete Cloth additionally therapy faster, lowering the time heavy equipment is idle on-site, which similarly minimizes emissions.

Durability and Longevity: Reducing Lifecycle Impact

Resilience Against Environmental Stress

Concrete impregnated material is designed to face up to harsh conditions, from excessive temperatures to moisture and corrosion. 8mm Concrete Cloth, in particular, provides sturdy durability, with a lifespan related to normal concrete however with higher resistance to cracking. This sturdiness potential buildings constructed with concrete cloth constructing substances require fewer repairs and replacements over time, lowering the want for extra substances and the related environmental fees of manufacturing and transportation.

Resistance to Degradation

Unlike timber or some plastics, Cement Blanket is no longer susceptible to rot, pests, or UV degradation. This steadiness ensures that buildings preserve their integrity except the want for chemical remedies or coatings, which can leach damaging materials into the environment. By keeping off these additives, concrete cloth constructing helps more healthy ecosystems round building web sites and reduces long-term air pollution risks.

Versatility and Adaptability: Supporting Green Design

Flexible Applications in Eco-Projects

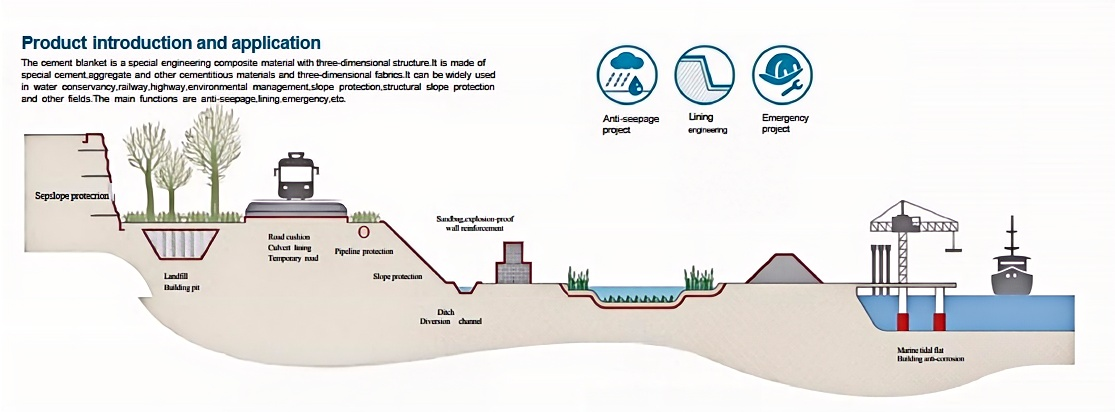

Concrete material constructing substances excel in a vary of sustainable building scenarios. 8mm Concrete Cloth is perfect for erosion control, inexperienced roofs, and transient or everlasting holding walls, the place its flexibility lets in it to conform to uneven terrain except compromising structural integrity. Cement Blanket is additionally used in catastrophe alleviation shelters, imparting quick, long lasting housing with minimal environmental disruption—critical for lowering the ecological influence of emergency responses.

Compatibility with Renewable Systems

Concrete impregnated cloth integrates seamlessly with renewable strength and inexperienced infrastructure. For example, it can be used to assemble bases for photo voltaic panels or aid structures for rainwater harvesting, improving the effectivity of these sustainable technologies. Its adaptability ensures that it suits into various eco-friendly designs, making it a versatile device for builders aiming to meet inexperienced constructing standards.

Conclusion: Embracing Eco-Friendly Construction with Concrete Impregnated Fabric

Concrete impregnated fabric—including 8mm Concrete Cloth and Cement Blanket —represents a enormous step ahead in sustainable construction. Its cloth efficiency, decreased electricity use, durability, and versatility make it a eco-conscious desire for present day projects. By minimizing waste, reducing emissions, and assisting long-lasting, low-maintenance structures, concrete material constructing aligns with the desires of decreasing the development industry’s environmental footprint. As greater builders prioritize sustainability, these progressive substances are set to play a pivotal position in growing greener, greater resilient constructed environments. Whether for small-scale landscaping or giant infrastructure projects, concrete impregnated material proves that power and sustainability can go hand in hand.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province