Coastal Erosion Control: Why HDPE Geomembrane Is the Go-To Barrier Material

Durable, Eco-Friendly Protection for Shorelines & Coastal Infrastructure

Coastal erosion is a world catastrophe pushed through capacity of rising sea levels, immoderate local weather (hurricanes, storm surges), and human activity. It devours shorelines, damages coastal homes, roads, and ecosystems, and threatens communities that consider on healthful coastlines for tourism, fishing, and safety. Traditional erosion manipulate methods—such as riprap (rock armor), concrete seawalls, and sandbags—often fail to stand the test of time: they’re heavy, high priced to install, prone to cracking, and disruptive to marine life. Enter HDPE Geomembrane: a progressive barrier material that combines strength, flexibility, and eco-friendliness to handle coastal erosion’s one-of-a-kind challenges. For engineers, municipal planners, and environmental managers, HDPE Geomembrane has come to be the gold prevalent for reliable, long-term coastal protection. This article explores why HDPE Geomembrane outperforms ordinary methods, its key advantages, imperative applications, and fine practices for installation—proving why it’s the go-to want for coastal erosion control.

1. The Coastal Erosion Challenge: Why Traditional Methods Fall Short

Limitations of Riprap, Concrete, and Sandbags

Coastal environments are unforgiving: saltwater corrosion, constant wave action, and fluctuating tides demand a barrier fabric that can face up to immoderate stress. Traditional methods, however, conflict to meet these demands. Riprap (large rocks) is heavy and steeply-priced to transport and install, often shifting or sinking beneath wave pressure—creating gaps the location erosion persists. Concrete seawalls are rigid, unable to adapt to soil action or storm surges, predominant to cracking and cave in over time. Sandbags are short at best, deteriorating in months and requiring constant replacement. Worse, these techniques disrupt marine ecosystems: riprap and concrete block daytime from conducting seagrass beds, even as sandbags leach chemical compounds and entice sediment. As coastal erosion accelerates, there’s an urgent prefer for a cloth that balances durability, flexibility, and environmental compatibility—something HDPE Geomembrane offers effortlessly. Unlike rigid concrete or cumbersome rock, Geomembrane conforms to shoreline contours, absorbs wave energy, and protects every infrastructure and ecosystems.

2. HDPE Geomembrane’s Core Advantages for Coastal Environments

Strength, Corrosion Resistance, and Flexibility

HDPE Geomembrane stands out as a coastal barrier cloth due to four game-changing residences that address the different rigors of saltwater, waves, and weather. First, best corrosion resistance: HDPE (high-density polyethylene) is inert to saltwater, salt spray, and marine chemicals—unlike metallic or concrete, which rust or degrade interior years. This resistance ensures HDPE Geomembrane maintains its integrity for 25–30 years, even in harsh coastal conditions. Second, extremely good tensile electrical energy and flexibility: The material’s immoderate elongation cost (500%+) approves it to adapt to soil settlement, wave movement, and minor shoreline shifts barring tearing—critical for withstanding storm surges that would crack rigid barriers. Third, impermeability: HDPE Geomembrane acts as a watertight barrier that prevents water from seeping beneath seashores or eroding soil from under infrastructure (e.g., seawalls, boardwalks). Fourth, eco-friendliness: Unlike concrete or riprap, HDPE Geomembrane is non-toxic, enabling sunlight hours and water to ignore through when used in vegetated coastal duties (e.g., salt marsh restoration). It moreover minimizes habitat disruption for the length of installation, as it’s lightweight and requires a great deal much less heavy gear than frequent methods. These advantages make HDPE Geomembrane now now not honestly durable, then again moreover a sustainable desire for balancing coastal security and ecological health.

3. Key Applications of HDPE Geomembrane in Coastal Erosion Control

Shorelines, Seawalls, Salt Marshes, and Beyond

HDPE Geomembrane’s versatility makes it excellent for a fluctuate of coastal erosion manipulate projects, each tailored to defend specific property and ecosystems:

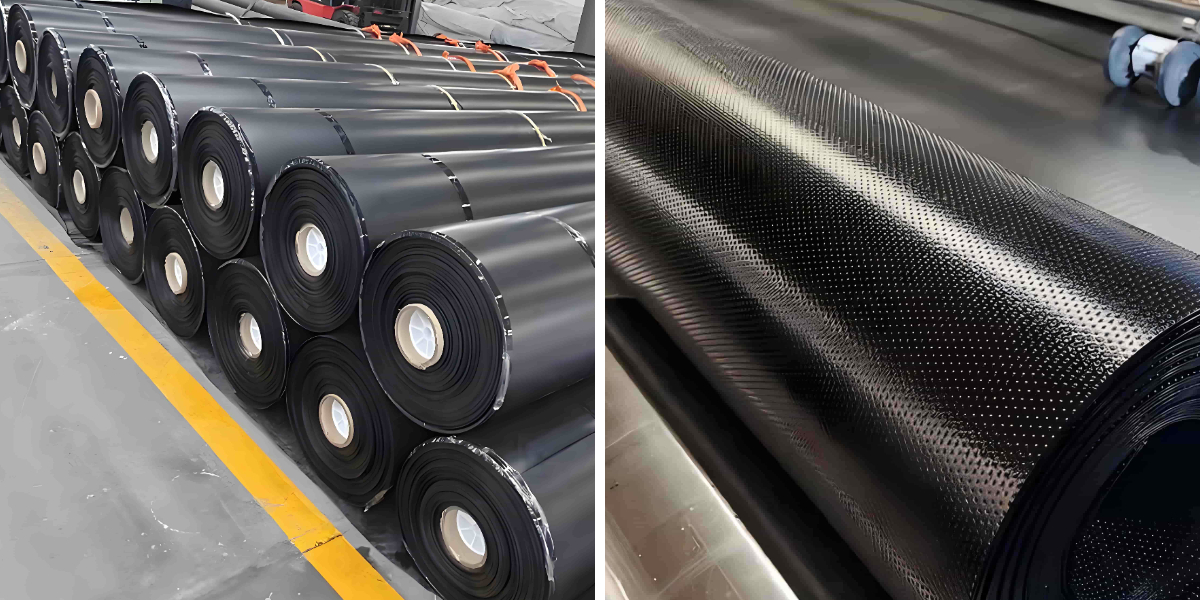

Shoreline Armoring: Installed alongside uncovered coastlines, HDPE Geomembrane creates a continuous barrier that absorbs wave electrical energy and prevents soil erosion. It’s regularly paired with a geotextile underlay for greater puncture protection and included with a skinny layer of sand or gravel to combination with the natural landscape. For high-wave areas, textured HDPE Geomembrane (with a hard surface) enhances friction, stopping sliding and bettering stability.

Seawall and Revetment Reinforcement: HDPE Geomembrane traces the face or base of seawalls and revetments, stopping water from seeping in the returned of the structure and inflicting undermining. It acts as a secondary barrier, extending the lifespan of existing concrete or rock seawalls via the usage of reducing corrosion and pressure.

Salt Marsh and Wetland Restoration: Wetlands are natural erosion buffers, then again they’re disappearing at an alarming rate. HDPE Geomembrane is used to create contained areas for salt marsh restoration: it lines shallow trenches to trap sediment and information the make bigger of native plant existence (e.g., cordgrass), which in a similar way stabilize the shoreline. The permeable nature of Geomembrane editions ensures water and nutritional vitamins gain plant roots, fostering healthful ecosystems.

Port and Harbor Protection: HDPE Geomembrane traces the slopes of ports, harbors, and jetties, defending them from wave action and sediment erosion. Its sturdiness makes it ideal for high-traffic marine areas, the area constant boat wakes and tidal shifts would damage weaker materials.

Coastal Road and Infrastructure Protection: Coastal highways, bridges, and residential areas are commonly at hazard of erosion. HDPE Geomembrane is set up alongside the edges of these structures to create a defending buffer, stopping soil loss and extending the existence of crucial infrastructure.

4. Installation & Maintenance Best Practices for Coastal HDPE Geomembrane

Ensuring Long-Term Performance in Harsh Conditions

Proper set up and renovation are quintessential to HDPE Geomembrane’s effectiveness in coastal environments—mistakes can lead to leaks, shifting, or premature failure. Follow these awesome practices:

Site Preparation: Clear the set up region of rocks, shells, and sharp particles (which can puncture Geomembrane). Level and compact the soil or substrate to create a smooth base, and lay a non-woven geotextile underlay to add extra security in opposition to abrasion from wave action. For uneven shorelines, contour the base to in form the natural slope, making certain full contact with the Geomembrane.

Welding and Seaming: Seams are the weakest elements of any Geomembrane system—use heat welding (the most reliable approach for HDPE) to create continuous, leak-proof seams. Overlap sheets with the resource of 15–20 cm and take a appear at each and every seam with air stress or vacuum checking out to make sure no gaps. For curved or vertical surfaces, use extrusion welding for precise, sturdy bonds.

Anchoring and Protection: Secure the HDPE Geomembrane to cease shifting from waves or tides. Bury the pinnacle thing in a trench (30–50 cm deep) and backfill with compacted soil, or use concrete anchors for vertical installations (e.g., seawalls). Cover the Geomembrane with a protective layer (sand, gravel, or vegetative soil) to protect it from UV radiation and bodily damage.

Maintenance: Conduct quarterly inspections (especially after storms) to check for tears, punctures, or lifting edges. Repair small damages with HDPE patches (welded in place) and replacement severely damaged sections immediately. Monitor the defending pinnacle layer—replenish sand or gravel if it’s washed away to stop UV exposure. With proper care, HDPE Geomembrane requires minimal maintenance, outlasting everyday strategies thru decades.

5. Environmental Compliance & Long-Term Cost Savings

Why HDPE Geomembrane Delivers Value Beyond Protection

Coastal erosion manipulate initiatives have to comply with strict environmental hints (e.g., EPA Clean Water Act, EU Marine Strategy Framework Directive) to protect marine existence and habitats. HDPE Geomembrane excels here: it’s non-toxic, recyclable, and properly applicable with eco-restoration projects, making it handy to meet regulatory requirements. Unlike concrete or riprap, which can disrupt fish spawning grounds or seagrass beds, HDPE Geomembrane helps biodiversity by using allowing vegetation amplify and minimizing habitat disturbance.

From a charge perspective, HDPE Geomembrane offers large long-term savings. While the preliminary set up rate would possibly additionally be comparable to riprap or concrete, its 25–30-year lifespan (vs. 10–15 years for ordinary methods) reduces choice and maintenance costs. It’s lightweight and accessible to transport, reducing down on transport and labor expenses—critical for a ways off coastal areas. Additionally, HDPE Geomembrane’s flexibility eliminates the desire for pricey formwork or personalized fabrication, rushing up project timelines and reducing downtime. For municipalities and venture managers, these monetary financial savings add up, making HDPE Geomembrane a low-cost funding in coastal resilience.

Conclusion: HDPE Geomembrane Is the Future of Coastal Erosion Control

Coastal erosion is a urgent threat, then again HDPE Geomembrane affords a reply that balances durability, flexibility, and environmental responsibility. Its viable to face up to saltwater, wave action, and excessive weather—while supporting ecosystems and complying with regulations—makes it the most fabulous choice for coastal protection. Whether you’re restoring a salt marsh, reinforcing a seawall, or defending a coastal highway, HDPE Geomembrane gives you reliable, long-term results that ordinary strategies can’t match.

By deciding on HDPE Geomembrane, you’re no longer really defending shorelines—you’re investing in the resilience of coastal communities and the health of marine ecosystems. Partner with a depended on supplier to pick out out the suitable thickness (1.5–2.0mm is huge for coastal projects) and set up team, and make positive your coastal erosion manipulate mission stands the take a appear at of time.

Ready to defend your shoreline with HDPE Geomembrane? Explore our differ of coastal-grade Geomembrane products, or contact our specialists for personalized recommendations. Invest in HDPE Geomembrane today—and construct a more resilient coastal future.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province