Cement Blanket: The Revolutionary Construction Material You Need to Know

In the ever - evolving world of construction, innovation is key to improving efficiency, durability, and cost - effectiveness. Cement blanket, additionally recognised as concrete cloth fabric, concrete cloth, or ditch liner, has emerged as a revolutionary building material that is transforming the industry. This article will explore the various aspects of cement blanket, from its unique features to its broad - ranging applications.

1. Exceptional Strength and Durability

1.1 Withstands Harsh Environments

Traditional construction materials often struggle when faced with harsh environmental conditions. For instance, regular concrete can crack and degrade when exposed to excessive temperatures, UV radiation, and chemical substances. Cement blanket, also known as concrete cloth fabric, on the other hand, is engineered to thrive in such harsh conditions. The concrete in the cement blanket is mixed with a robust fabric backing, which is normally made of a synthetic material like polypropylene. This fabric is resistant to UV rays, preventing the concrete from being damaged by long - term sun exposure. In a study conducted in a coastal location with high salt - water exposure and extreme sunlight, a cement blanket - lined structure retained 90% of its original strength after 5 years, whilst a traditional concrete structure in the same vicinity showed symptoms of extensive degradation, with a 30% loss in strength. This makes cement blanket an ideal choice for projects in areas with extreme climates, such as deserts, where high temperatures and UV intensity are common, or near industrial sites where chemical exposure is a concern.

1.2 Maintains Performance Over Time

The unique structure of the cement blanket, or concrete cloth as it is often called, contributes to its long - term performance. The concrete inside the blanket is evenly distributed and held in place via the fabric matrix. This prevents the concrete from transferring or separating, ensuring that the structure maintains its integrity over time. Unlike common concrete buildings that may develop cracks due to settlement or vibration, the flexible nature of the cement blanket allows it to adapt to minor ground movements without significant damage. A case study of a canal lining assignment in a region with seasonal freeze - thaw cycles showed that a cement blanket - lined canal remained intact and functional after 10 years, whilst a neighboring canal lined with ordinary concrete required multiple repairs due to cracking and spalling. With a lifespan of up to 25 - 50 years depending on the application and environmental conditions, cement blanket reduces the need for pricey and time - consuming maintenance and retrofits, making it a cost - effective choice for long - term infrastructure projects.

2. Superior Installation Efficiency

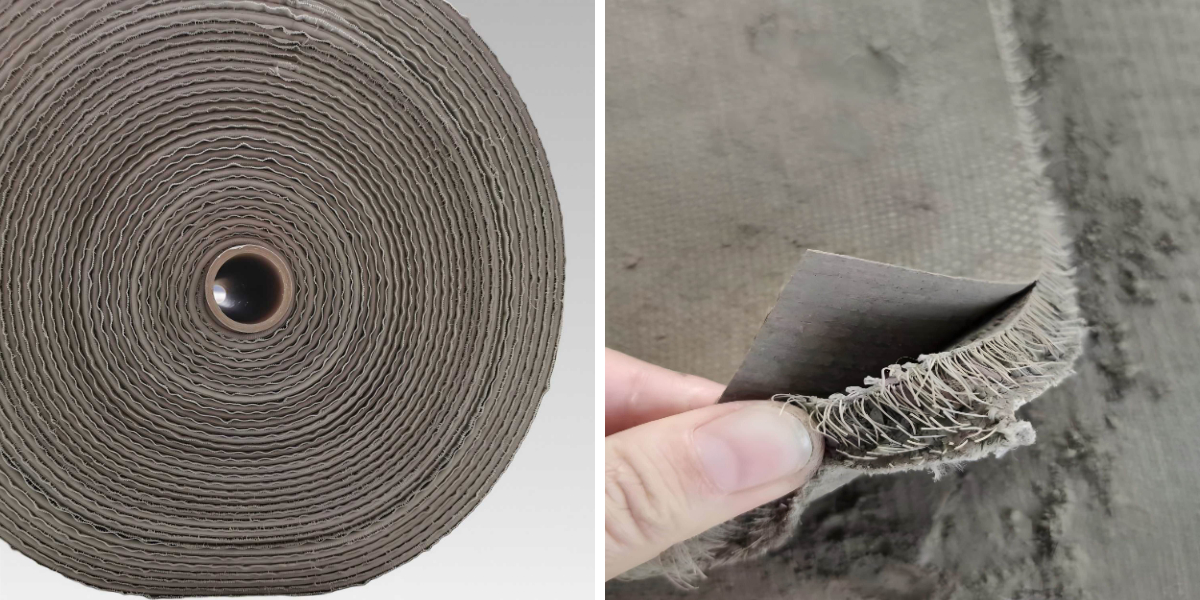

2.1 Simplifies the Installation Process

Traditional concrete installation is frequently a labor - intensive and time - eating process. It requires mixing concrete on - site, pouring it into forms, and ready for it to cure. Cement blanket, also referred to as ditch liner, however, streamlines the installation procedure significantly. The cement blanket comes in rolls, which are lightweight and easy to transport to the development site. It can be unrolled and positioned directly on the floor where it is needed, whether it is for lining a canal, developing a path, or constructing a retaining wall. The installation does not require specialised gear or a massive workforce. For example, in a small - scale garden path project, a single employee was able to deploy a 50 - square - meter cement blanket in simply one day, whilst the same region would have taken at least three days to be paved with regular concrete, thinking about the time for mixing, pouring, and leveling. Additionally, the cement blanket can be easily cut to match any form or size, imparting flexibility in design and installation.

2.2 Reduces Installation Time

The pace of installation with cement blanket, or concrete cloth fabric, directly influences mission timelines. For emergency projects, such as repairing a broken avenue or flood - control structures, the rapid - setting nature of cement blanket is a game - changer. Once the cement blanket is unrolled and wetted, it begins to set inside hours. In a flood - affected area, a brief flood - wall made of cement blanket was erected inside 24 hours, presenting instantaneous safety towards similarly flooding. In contrast, constructing a ordinary concrete flood - wall would have taken at least a week, thinking about the time for formwork, concrete pouring, and curing. A study by the Construction Industry Institute found that tasks using cement blanket decreased the normal building time by an common of 35% in contrast to tasks using usual concrete methods. This acceleration now not solely cuts labor charges however additionally minimizes disruptions to the surrounding surroundings and activities.

3. Versatile Applications

3.1 Beyond Traditional Concrete Uses

Traditional concrete is more often than not used for structural functions such as constructing foundations, walls, and floors. Cement blanket, also known as concrete cloth, however, has a plenty broader vary of applications. In environmental projects, it is used for riverbank and canal lining to stop erosion. The fabric - bolstered concrete in the cement blanket can face up to the pressure of flowing water, stopping the soil from being washed away. In a river restoration project, cement blanket was once used to line a 1 - kilometer stretch of the riverbank. The end result was once a huge discount in soil erosion, and the boom of vegetation on the cement blanket - lined financial institution helped to enhance the ecological environment. In landscaping, cement blanket can be used to create walkways, patios, and even ornamental features. It can be formed and coloured to healthy the aesthetic necessities of the project. For example, in a luxurious hotel's garden, cement blanket used to be used to create a winding, cobblestone - like route that blended seamlessly with the surrounding landscape.

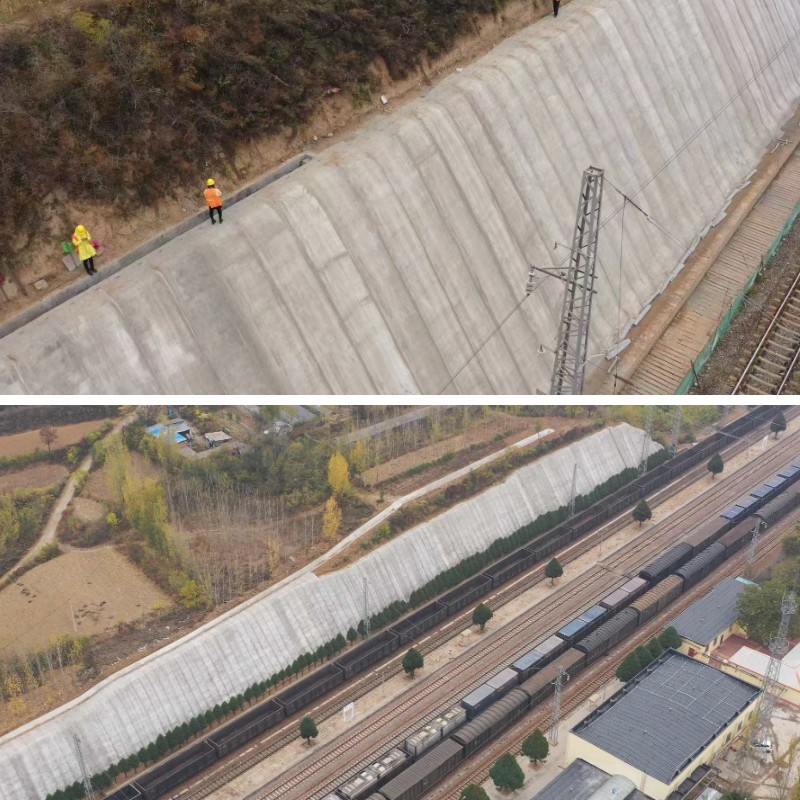

3.2 Customizable for Specific Needs

Cement blanket, or ditch liner, is tremendously adaptable to exclusive challenge requirements. It comes in a number thicknesses, ranging from 5mm for light-weight purposes like small - scale backyard paths to 50mm for heavy - duty industrial and infrastructure projects. The dimension of the rolls can additionally be customized, making it appropriate for tasks of any scale, from a small outside mission to a massive - scale toll road construction. For a giant - scale infrastructure project, such as a motorway embankment slope protection, a thicker and larger - sized cement blanket can be used to furnish most balance and protection. In a residential driveway project, a thinner and extra bendy cement blanket can be chosen to healthy the aesthetic and load - bearing requirements. The capacity to personalize cement blanket ensures that it can be tailor-made to healthy the particular wishes of any development project.

4. Cost - Effectiveness

4.1 Balances Initial and Long - Term Costs

While the preliminary fee of cement blanket, also called concrete cloth fabric, may additionally be barely greater than some common concrete substances on a per - rectangular - meter basis, its lengthy - time period price financial savings are substantial. Traditional concrete constructions frequently require everyday maintenance, such as repainting, patching cracks, and changing broken sections. Cement blanket, due to its sturdiness and low - renovation nature, reduces these lengthy - time period prices significantly. A 10 - yr lifecycle evaluation of a 10 - kilometer rural avenue task confirmed that the use of cement blanket for the avenue floor resulted in complete prices (initial + maintenance) 25% decrease than the use of regular concrete. The financial savings got here from decreased restore expenses due to the best electricity and sturdiness of the cement blanket, as nicely as fewer replacements over time. For industrial amenities with heavy automobile traffic, the price financial savings are even extra pronounced. A manufacturing facility yard paved with cement blanket required 70% fewer pothole repairs over 15 years in contrast to a yard paved with usual asphalt, ensuing in tremendous financial savings in preservation costs.

4.2 Saves in Specific Projects

In sure projects, such as slope stabilization in mountainous areas, the fee - effectiveness of cement blanket, or concrete cloth, is in particular evident. Traditional slope stabilization techniques regularly contain transporting massive quantities of heavy materials, such as rocks and concrete blocks, to the site. This can be extraordinarily costly, mainly in far off areas the place transportation expenses are high. Cement blanket, on the different hand, is light-weight and can be without difficulty transported to the site. In a mountain slope stabilization challenge in a far off area, the use of cement blanket with nearby soil as infill decreased the fabric transportation charges by means of 60% in contrast to the usage of typical rock - primarily based stabilization methods. The light-weight nature of cement blanket additionally reduces the gasoline consumption for transportation, making it a extra environmentally pleasant and fee - tremendous option.

5. Environmental Benefits

5.1 Reduces Carbon Footprint

The manufacturing of normal concrete is power - intensive and contributes appreciably to carbon emissions. Cement blanket, also known as ditch liner, in contrast, has a decrease carbon footprint. The manufacturing system of cement blanket requires much less strength as it does no longer contain the massive - scale mixing and curing techniques related with ordinary concrete production. Additionally, the light-weight nature of cement blanket reduces the electricity required for transportation. A find out about via the Green Building Council discovered that the use of cement blanket in a development challenge can minimize the carbon emissions related with fabric manufacturing and transportation via up to 30% in contrast to the use of normal concrete. This makes cement blanket a extra sustainable preference for environmentally mindful building projects.

5.2 Promotes Vegetation Growth

In some applications, such as slope safety and erosion control, cement blanket, or concrete cloth fabric, can be designed to promote vegetation growth. The material matrix of the cement blanket permits for the infiltration of water and nutrients, growing a appropriate surroundings for flora to grow. When used for slope protection, the increase of vegetation on the cement blanket - blanketed slope no longer solely helps to in addition stabilize the soil however additionally improves the aesthetic look of the region and contributes to biodiversity. In a slope restoration task in a nature reserve, cement blanket was once used, and inside a year, a range of native vegetation had grown on the blanket - included slope, bettering the ecological fee of the area.

In conclusion, cement blanket, with its concrete cloth fabric, concrete cloth, or ditch liner variations, presents a extensive vary of advantages that make it a revolutionary building material. Its strength, durability, set up efficiency, versatility, value - effectiveness, and environmental advantages make it an perfect preference for a range of development projects, from small - scale residential to massive - scale infrastructure developments. As the development enterprise continues to are searching for extra modern and sustainable solutions, cement blanket is set to play an increasingly more necessary role.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province