Case Study: Successful HDPE Liner Installation in a Challenging Climate

Installing an impermeable geomembrane in intense climates—where temperature fluctuations, harsh weather, and unpredictable stipulations check cloth and set up resilience—requires cautious planning, specialised techniques, and satisfactory materials. This case find out about explores a profitable hdpe geomembrane set up challenge in a place with severe seasonal variations, highlighting how proactive strategies, specialist execution, and adherence to high-quality practices overcame climate-related challenges. The project, centered on a municipal wastewater containment facility, demonstrates how suitable geomembrane set up and extremely good hdpe geomembrane can supply reliable, long-lasting impermeability even in unforgiving environments.

Project Overview: Containment Needs in a Hostile Climate

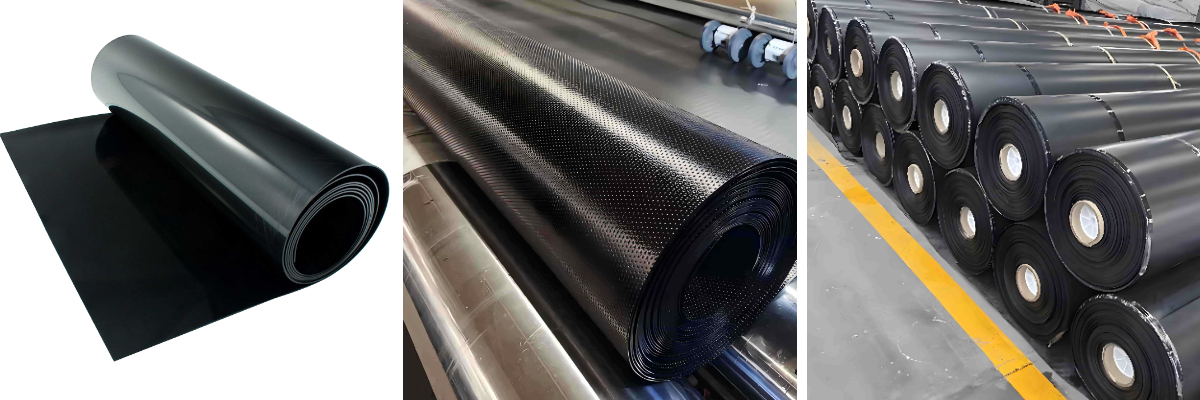

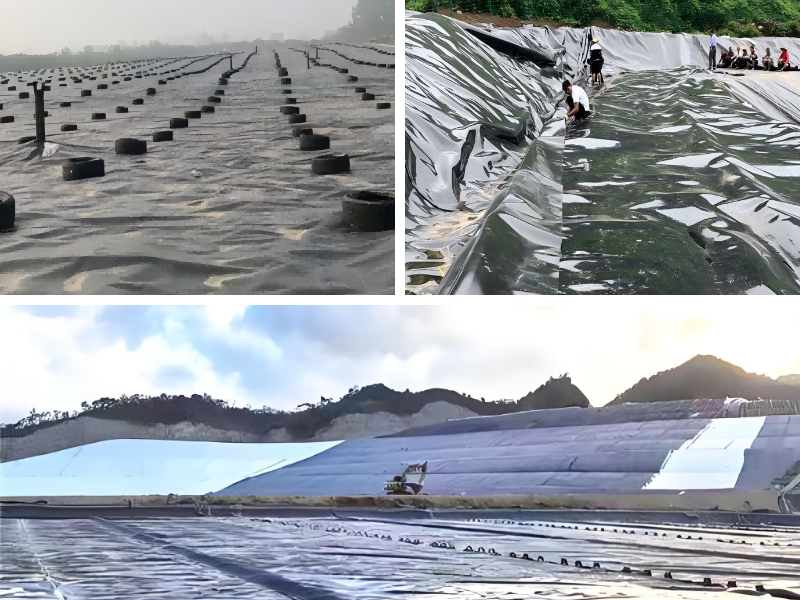

The undertaking aimed to improve the containment gadget of a wastewater remedy plant positioned in a vicinity characterised by using sizzling summers, freezing winters, and sudden, excessive rainstorms. The facility required an impermeable geomembrane answer to line two major storage ponds, stopping leaks that may want to contaminate neighborhood groundwater and ecosystems. HDPE geomembrane was once chosen for its durability, chemical resistance, and potential to stand up to severe temperature swings—critical residences for withstanding the climate’s harsh conditions. The undertaking lay in executing geomembrane set up at some point of a slender window between intense climate events, whilst making sure seams and cloth integrity remained uncompromised via temperature fluctuations and moisture.

Pre-Installation Planning: Mitigating Climate Risks

Success started out with rigorous pre-installation planning tailor-made to the climate’s special challenges. The crew first carried out a precise web site evaluation to map drainage patterns, soil conditions, and microclimates throughout the set up area—key for optimizing geomembrane set up logistics. To tackle temperature-related risks, the mission unique hdpe geomembrane with stronger UV stabilization and flexibility, making sure it would face up to brittleness in freezing temperatures and degradation in severe sunlight. A climate monitoring gadget used to be carried out to tune real-time conditions, permitting the crew to pause work throughout unexpected rainstorms or temperature extremes that may want to compromise geomembrane set up quality. Additionally, the crew sourced substances from a dealer with ride in climate-resistant hdpe geomembrane, making sure compliance with enterprise requirements for intense environments.

Overcoming Installation Challenges: Adapting to Extreme Conditions

Temperature Fluctuations and Material Handling

Extreme temperature swings posed the most sizeable venture to geomembrane installation. During summer, sunlight hours temperatures soared, growing the threat of hdpe geomembrane stretching or warping if treated improperly. To mitigate this, the crew scheduled set up for early mornings and late afternoons, when temperatures have been moderate. HDPE geomembrane rolls have been saved in shaded areas and unrolled progressively to forestall speedy temperature adjustments that may want to reason fabric stress. In cooler conditions, the crew used specialised heating tools to heat hdpe geomembrane edges earlier than welding, making sure acceptable fusion—critical for preserving impermeable geomembrane integrity when temperatures dropped beneath most reliable welding ranges.

Moisture and Rainstorm Preparedness

Sudden rainstorms threatened to introduce moisture to the set up site, which should contaminate seams and prevent welding. The crew applied a proactive drainage plan, grading the web page to direct water away from the work location and putting in transient storm barriers. Impermeable geomembrane sheets have been deployed and welded in sections, with every finished part blanketed with a shielding layer in a single day to defend it from surprising rain. If moisture used to be detected on hdpe geomembrane surfaces, the group wholly dried the place the usage of industrial blowers earlier than intending with welding—ensuring no water was once trapped in seams, which would weaken bond electricity and compromise impermeability.

Soil Stability and Base Preparation

Climate-related soil instability—exacerbated through freeze-thaw cycles and heavy rainfall—required meticulous base coaching earlier than geomembrane installation. The group compacted the soil in layers, trying out density at every stage to forestall settling that may want to stress the hdpe geomembrane over time. A geotextile cushion layer was once hooked up under the hdpe geomembrane to guard it from sharp soil particles and limit friction at some point of temperature-induced growth and contraction. This base education now not solely safeguarded the impermeable geomembrane from bodily harm however additionally ensured a smooth, steady floor for welding, optimizing seam strength.

Quality Control: Ensuring Long-Term Impermeability

Stringent excellent manipulate (QC) protocols had been necessary to the project’s success, specially given the climate’s demands. Every segment of geomembrane set up was once monitored through licensed QC inspectors, who confirmed cloth quality, welding parameters, and seam integrity. Welded seams—critical to the impermeable geomembrane’s performance—underwent rigorous testing, along with peel tests, shear tests, and vacuum tests, to make certain they met or surpassed enterprise standards. Any misguided seams had been right now repaired and retested, with documentation maintained for future reference. Post-installation, the crew performed a full-system leak detection survey, the use of electrical checking out to become aware of any hidden imperfections in the hdpe geomembrane that may want to lead to leaks in excessive weather.

Project Outcomes and Lessons Learned

The assignment used to be achieved on time table and inside budget, handing over a entirely functional, impermeable containment device that has withstood more than one excessive climate events. The hdpe geomembrane has maintained its integrity thru sizzling summers and freezing winters, with no leaks or overall performance problems suggested to date. Key training from the challenge consist of the significance of climate-specific cloth selection—choosing hdpe geomembrane tailor-made to temperature extremes and UV exposure—and bendy set up scheduling to keep away from damaging weather. Proper base coaching and rigorous QC additionally emerged as non-negotiable for making sure geomembrane set up success in difficult climates. The mission demonstrates that with cautious planning and specialist execution, hdpe geomembrane can supply dependable impermeability even in the most antagonistic environments.

Conclusion: HDPE Geomembrane as a Climate-Resilient Solution

This case find out about underscores the versatility and reliability of hdpe geomembrane in difficult climates, proving that with strategic planning, ideal geomembrane set up techniques, and interest to climate-specific risks, impermeable geomembrane structures can thrive in unforgiving conditions. The project’s success highlights that investing in terrific hdpe geomembrane and skilled set up teams—rather than slicing corners—delivers long-term price by using minimizing maintenance, repairs, and environmental risk. For groups dealing with comparable containment challenges in severe climates, this case find out about serves as a blueprint for attaining profitable geomembrane set up and making sure lasting impermeability.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province