10 Innovative Uses for Cement Blankets You Haven't Considered

Introduction: Rethinking a Versatile Solution

When you hear "cement blanket," the idea generally jumps to fundamental slope stabilization or emergency repair. However, this flexible, fiber-reinforced composite fabric is quietly revolutionizing initiatives some distance past the development site. Its special properties—rapid deployment, first-rate durability, and conformability—make it a secret weapon for engineers, environmental managers, and innovative professionals. This article unveils ten groundbreaking functions that mission traditional thinking, with a one of a kind focal point on fundamental protection and environmental purposes like Petrochemical Containment and Bund Lining. Prepare to find out how this progressive fabric is fixing complicated issues throughout various industries.

1. Rapid-Deployment Secondary Containment & Bund Lining

In industrial settings, pace and reliability in protection measures are non-negotiable. Traditional concrete Bund Lining—the barrier round storage tanks to comprise spills—involves prolonged pours, curing times, and complicated forming. Cement blankets seriously change this process. They can be unrolled without delay onto organized subgrades, hydrated, and cured to shape a seamless, impermeable monolithic liner in a fraction of the time. For Petrochemical Containment, this potential substantially decreased downtime all through facility enhancements or emergency repairs. The material's chemical-resistant system is perfect for containing hydrocarbons, supplying a strong secondary layer of protection that seamlessly integrates into current infrastructure.

2. Sculpted, Aesthetic Landscaping and Art Installations

Move over, poured concrete. Landscape architects and artists are leveraging the malleability of cement blankets to create organic, flowing forms. The cloth can be draped over customized armatures to create seamless, textured planters, benches, water features, and even large-scale art. This utility extends to purposeful splendor in industrial design: a integral Bund Lining region can be sculpted with mild curves and coloured or stamped for the duration of installation, remodeling a utilitarian security function into an intentional diagram issue that enhances the surrounding environment.

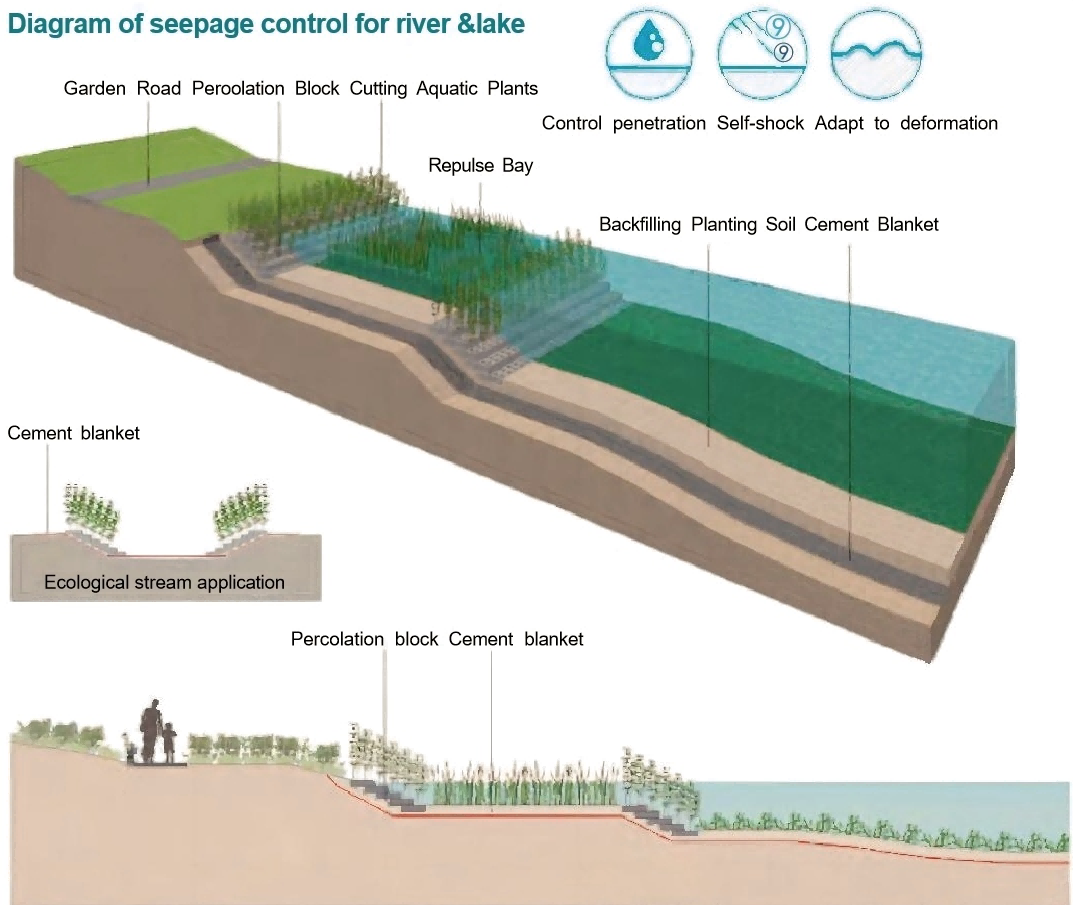

3. Pre-Cast, On-Site Canal and Ditch Linings

Lining irrigation canals or drainage ditches with concrete normally requires costly forming and curing in variable weather. Cement blankets provide a streamlined alternative. Rolled out without delay into the channel profile and anchored, they hydrate to structure a durable, high-strength lining that minimizes water loss and prevents erosion. This technique is distinctly treasured for preserving clean, environment friendly channels in touchy areas adjoining to Petrochemical Containment zones, the place stopping contaminated runoff is paramount. The set up minimizes web page disturbance and is frequently quicker than ordinary methods.

4. Temporary Event Infrastructure and Ground Stabilization

From track gala's to humanitarian useful resource camps, developing stable, mud-free surfaces is a regular challenge. Cement blankets furnish an instant, roll-out answer for growing get admission to roads, staging areas, and gear pads. Once the tournament concludes, the hardened floor can be damaged up (if temporary) or left as a everlasting improvement. This use additionally applies to developing secure, secure foundations for transient Bund Lining round gasoline or water storage tanks at far flung tournament sites, making sure environmental safety even for temporary operations.

5. Protective Caps for Landfills and Environmental Remediation

Capping closed landfills or contaminated web sites requires a durable, impermeable layer that prevents leachate formation and controls fuel emissions. Cement blankets can serve as a protecting cap or as a factor inside a multi-layer capping system. Their fast set up reduces the window of environmental exposure, and their rugged floor offers instantaneous erosion resistance. In eventualities involving historic Petrochemical Containment failures, they can be used to rapidly encapsulate and stabilize affected areas, mitigating similarly environmental influence all through longer-term remediation planning.

6. High-Performance Firebreaks in Wildland Areas

In wildfire-prone regions, developing positive firebreaks is critical. Cement blankets can be deployed through floor crews or even dropped from plane in key strategic locations. Once hydrated via herbal dew, rain, or a mild spray, they treatment into a non-combustible mineral barrier that stops the enhance of floor fire. This revolutionary use offers a rapid-response device for defending indispensable infrastructure perimeters, such as amenities the place Petrochemical Containment is a foremost concern, including a layer of fire-resistant protection to storage bunds and containment areas.

7. Underwater Pipeline and Cable Protection

Protecting subsea or sub-fluvial infrastructure from abrasion, anchor damage, and scour is a steady engineering challenge. Cement blankets can be deployed underwater through divers or ROVs, conforming to pipelines or cables on the seabed. Upon curing, they create a solid, protecting armor jacket. This utility is indispensable for securing intake/outfall strains or pipelines close to coastal facilities, the place they additionally act as a stabilized Bund Lining equal for submerged infrastructure, stopping erosion that may want to expose and jeopardize the assets.

8. Modular, Rapid-Assembly Flood Defense Walls

As local weather alternate will increase flood frequency, communities want adaptable protection systems. Interlocking panels or rolls of cement blankets can be pre-positioned and unexpectedly deployed to construct brief flood walls, door barriers, or to enhance present levees. Hydrated on site, they fuse into a continuous, water-tight barrier. This thought is without delay relevant to improving Petrochemical Containment throughout flood events, the place a quick-to-assemble secondary wall can be erected round storage tank bunds to defend in opposition to overtopping from flash floods.

9. Durable Flooring for Heavy Industrial & Agricultural Use

Concrete flooring in barns, warehouses, or processing flora crack beneath heavy masses and chemical exposure. Cement blankets can be established as a thick, wear-resistant overlay over present broken concrete. The end result is a seamless, joint-free floor that is effortless to smooth and notably durable. In agricultural or industrial settings the place Petrochemical Containment for saved fuels or chemical substances is needed, this seamless ground can be sloped at once to a sump or built-in with a Bund Lining, growing an easy-to-maintain, impermeable principal containment surface.

10. Reinforced Vegetated Gabions and Green Walls

Combining structural energy with environmental benefits, cement blankets can shape the outer shell of "soft" gabion structures. Filled with soil and planted with native vegetation, these devices supply exquisite erosion manipulate with ecological value. This bio-engineered method is ideal for stabilizing slopes whilst bettering habitat. In industrial settings, such inexperienced partitions can be strategically used as ornamental and practical outer obstacles for Bund Lining areas, softening the visible influence of containment infrastructure whilst including an more layer of stabilization and environmental integration.

Conclusion: A Material Limited Only with the aid of Imagination

Cement blankets have decisively damaged free from their normal niche. From growing instantaneous Petrochemical Containment options and aesthetic Bund Lining to forming firebreaks and underwater armor, their utility is confined solely by way of creativity and engineering insight. This versatility stems from their core benefits: speed, strength, and simplicity. As industries face growing strain to work faster, safer, and with increased environmental responsibility, progressive substances like cement blankets will proceed to upward push to the challenge. The subsequent time you come upon a hassle involving protection, stabilization, or fast construction, reflect onconsideration on whether or not this roll-out answer may simply be the groundbreaking reply you need.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province