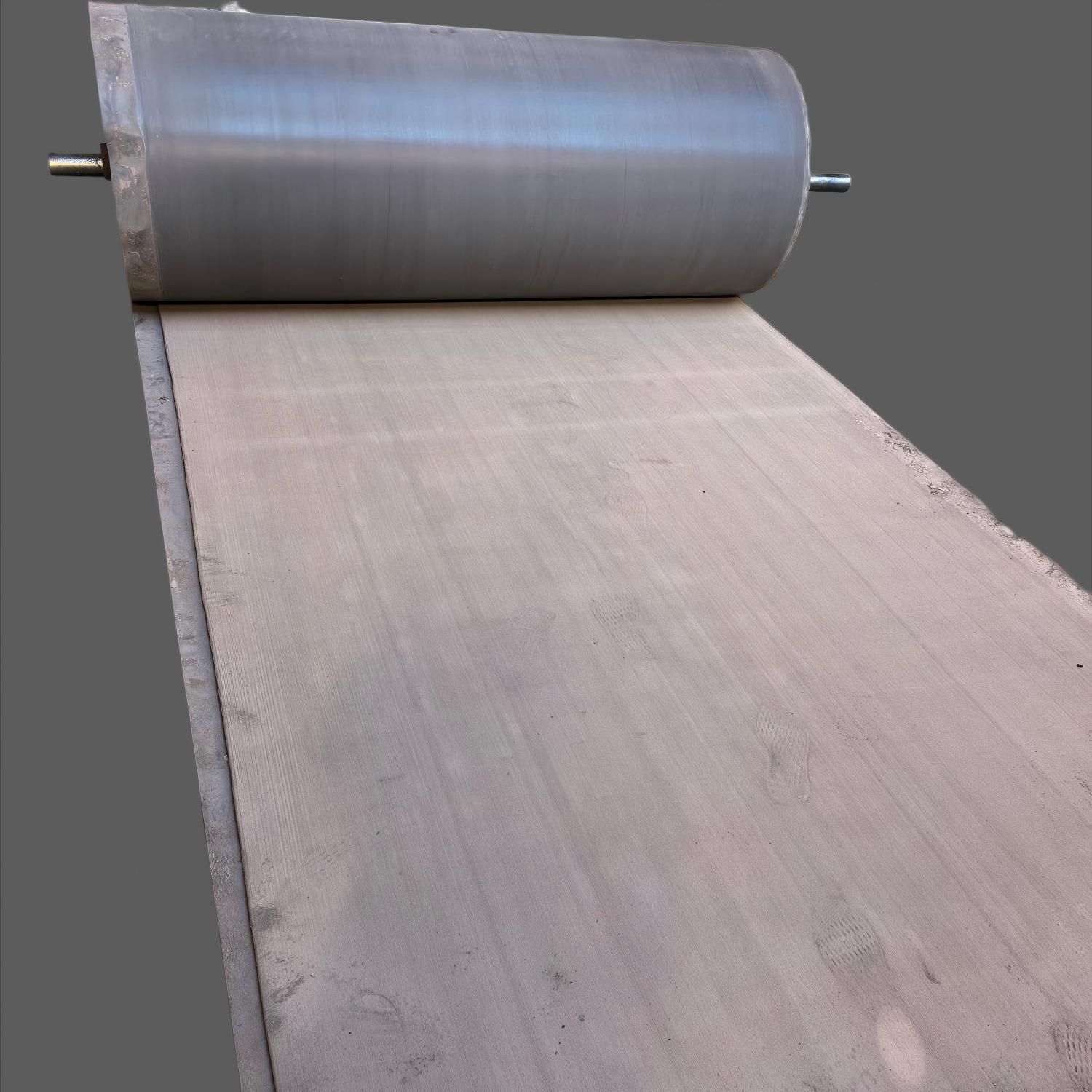

Fast-Setting Concrete Cloth

1. Rapid construction

After laying, it solidifies by watering, sets within 24 hours, and can reach its strength within 3 days, which is more than 10 times faster than traditional concrete. It is suitable for emergency repairs and projects.

2. Save labor and materials

No need for templates or mixing equipment, 2 people can operate, reducing labor costs; High material utilization and minimal waste.

3. Lightweight and flexible

Roll packaging, convenient transportation; Can be trimmed, bent, and adapted to complex terrain.

4. High strength and durability

Fiber reinforced crack resistance, corrosion resistance, UV resistance, and long service life.

Product Introduction:

Fast-Setting Concrete Cloth is an innovative geosynthetic material that combines cement-based materials with fiber weaving technology. The core principle is to uniformly impregnate dry concrete mixture (including cement, sand, additives, etc.) into a three-dimensional fiber skeleton through a special process, forming a flexible blanket like structure that can be curled. After encountering water, dry concrete undergoes hydration reaction and can harden into a high-strength, waterproof and fireproof concrete layer within 24 hours, combining the durability of traditional concrete with the flexibility of textile materials.

Product characteristics

1. Easy to use: It can be provided in bulk or rolled up, making it convenient for manual loading, unloading, and transportation without the need for large lifting machinery. Concrete is prepared according to scientific proportions and does not require on-site preparation.

2. Rapid solidification molding: After watering and hydration reaction, its size and shape can still be processed within 2 hours, and it can harden to 80% strength within 24 hours. It can also achieve rapid solidification or delayed solidification through special formulas.

3. Environmentally friendly: It is a low-quality and low-carbon technology that uses 95% less materials than commonly used concrete in many applications. The alkali content is limited, the erosion rate is very low, and the impact on the local ecology is minimal.

4. Flexible application: It has good drape and can conform to the complex shape of the covered object surface, even forming a hyperbolic shape. Before solidification, it can be cut or trimmed freely with ordinary hand tools.

5. High material strength: Fibers play a role in enhancing material strength, preventing cracking, and absorbing impact energy to form failure modes.

6. Long term durability: It has good chemical resistance, resistance to wind and rain erosion, and will not undergo ultraviolet degradation even in sunlight.

7. Good waterproof performance: The bottom has a waterproof layer, making it completely waterproof and enhancing the material's chemical resistance.

Product Parameters:

surveillance project | DYSNT-A1 | DYSNT-B1 | DYSNT-C1 | Test basis | remarks |

length (M) | 10--50 | / | |||

width (M) | 1--3 | / | |||

thickness (mm) | 6mm/8mm/9mm/10mm/12mm/15mm/20mm | / | |||

Compressive strength (MPa) | ≧50 | ≧70 | ≧85 | GB/T17671-2021 | |

Flexural strength (MPa) | ≧13 | ≧18 | ≧22 | GB/T 7019-2014 | |

Flexural strength retention rate after freeze-thaw cycles (%) | ≧85% | ≧90% | ≧90% | GB/T 50082-2009 | The freezing and thawing cycle from 50 to 200 times changed the indexes accordingly |

Water quality requirements for hydration | running water | Tap water, sea water | Tap water, seawater, sewage | / | |

Construction temperature conditions | · Construction above 0℃ | · Construction above-5℃ | · Construction above-5℃ | / | |

fire protecting performance | B1 | GB 8624-2012 | |||

Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||

Copper (total copper) (mg/L) | ≤100 | ||||

Zinc (total zinc) (mg/L) | ≤100 | ||||

Cadmium (total) (mg/L) | ≤1 | ||||

Lead (total lead) (mg/L) | ≤5 | ||||

Total chromium (mg/L) | ≤15 | ||||

Nickel (total nickel) | ≤5 | ||||

Arsenic (total) | ≤5 | ||||

Product Applications:

1. Water conservancy engineering

Slope protection and erosion prevention: Cement blankets are used to cover river channels and reservoir embankments to prevent soil erosion, and ecological greening is achieved by planting grass seeds.

Anti leakage treatment: laying underground pipelines and inner walls of water tanks to replace traditional waterproofing membranes and reduce the risk of leakage.

2. Transportation infrastructure

Road repair: Quickly lay temporary roads after earthquakes and floods, allowing light vehicles to pass within 2 hours.

Permanent pavement: airport runways and emergency lanes on highways are reinforced to reduce cracks and ruts.

3. Disaster prevention

Flood control embankment: on-site roll and harden, replace sandbags, and construct impact resistant barriers.

Seismic resistant structure: used for strengthening building foundations and enhancing overall seismic performance.

4. Ecological Engineering

Mine reclamation: Covering exposed rock surfaces to prevent dust and promote vegetation restoration.

Wetland protection: Build artificial bird nests and trails to reduce interference with the natural environment.

5. Temporary and permanent buildings

Military facilities: Field hospitals and command posts can be quickly built with bulletproof and explosion-proof functions.

Civil buildings: roof waterproof layer, wall decorative panels, replacing traditional concrete slabs to reduce structural load.

Cement blankets are reshaping traditional concrete application scenarios with their dual advantages of "material revolution+construction innovation". From hydraulic engineering to ecological restoration, from disaster prevention to smart cities, its lightweight, rapid hardening, environmentally friendly and durable characteristics provide efficient and sustainable solutions for infrastructure construction. With technological iteration, the future application boundaries will continue to expand, becoming an important growth point in the field of geotechnical materials.